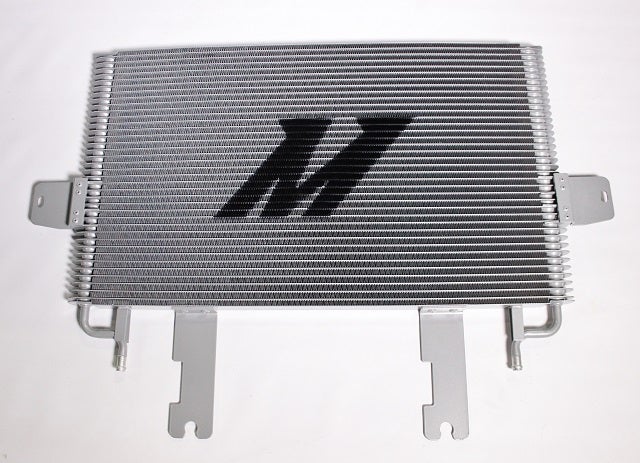

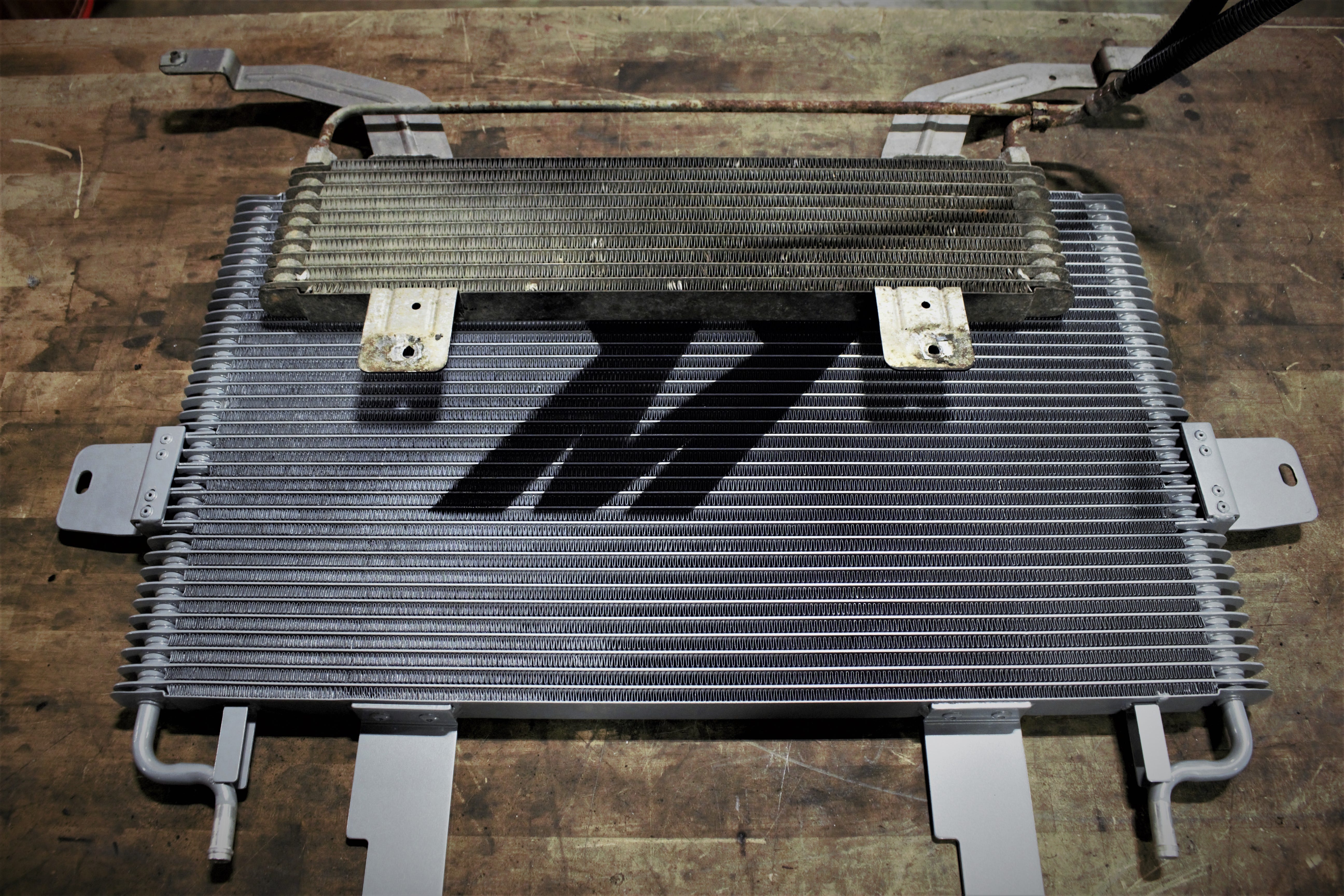

Sometimes there are products we can't wait to get on the market. The sense of urgency follows positive feedback after a release or hinting at a recently started project. There's pride in giving people what they want, what they need. When our 2003-2007 6.0L Powerstroke Transmission Cooler Kit was released, the question that kept coming was if it would fit the 7.3L. What followed was a "no, sorry." That didn't sit well with us. The efforts grew exponentially as more questions surfaced about fitment, and as the number of requests to make a direct fit kit increased.

In retrospect, it would have been best to provide all you 7.3L owners with upgraded cooling when the transmission cooler first launched. The reason why our 6.0L kit wasn't on option then was due to the hose routing. The lines are different. The 6.0L already has hoses that can adapt to our cooler without the necessity of lines from us. The inlets and outlets are in different spots here, so we needed to carefully design hoses that

![Love Is in the [Charge] Air - Secondary Radiator R&D, Part 2: Prototype Testing and Data](https://www.mishimoto.eu/media/magefan_blog/2016/07/015-2-1.jpg)