Going with the Flow: SuperFlow Dynamics SF-1020 - Flow Bench Equipment Profile

Performance is always on the enthusiast's mind. So, if you find us deep in thought behind the wheel, we're usually pondering what parts or tweaks will squeeze out another few drops of power. We here at Mishimoto have the same thoughts and are on a mission to achieve that performance potential. Since most modern vehicles, even the performance-oriented models, are left breathing through straws thanks to stringent standards and regulations, reducing restrictions in the intake and intercooler systems is one of the quickest routes to adding some pep to any engine's step.

Improving your vehicle's respiratory system is just one of our areas of expertise since more air means more power. However, how do we know we're on the right track for a deeper breathing engine? Making things bigger is one option, but there's so much more to flow dynamics than just a big pipe that requires precision testing, and we have the right tool for the job.

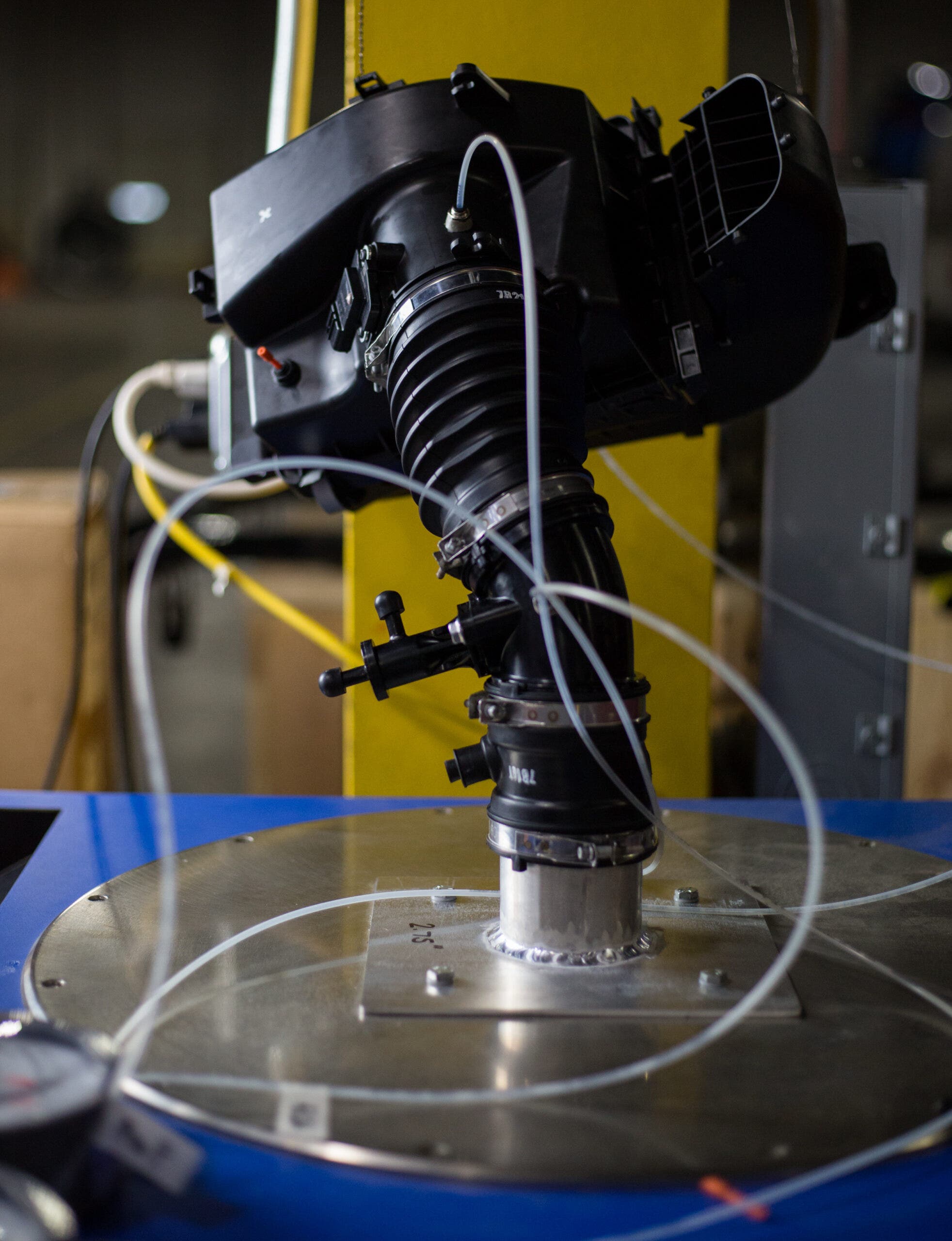

Enter the Superflow Dynamics SF-1020 flow bench. This model is the top dog of Superflow's flow bench range, equipped with sophisticated air pumps that allow our engineers to push or pull specific air pressures through the test component. Specifically, this flow bench can adjust its variable orifice to dial in precise flow ratings from 25 to 1000 CFM, or cubic feet of air moved per minute, allowing our engineers to dial in flow ratings that simulate the actual load on the component.

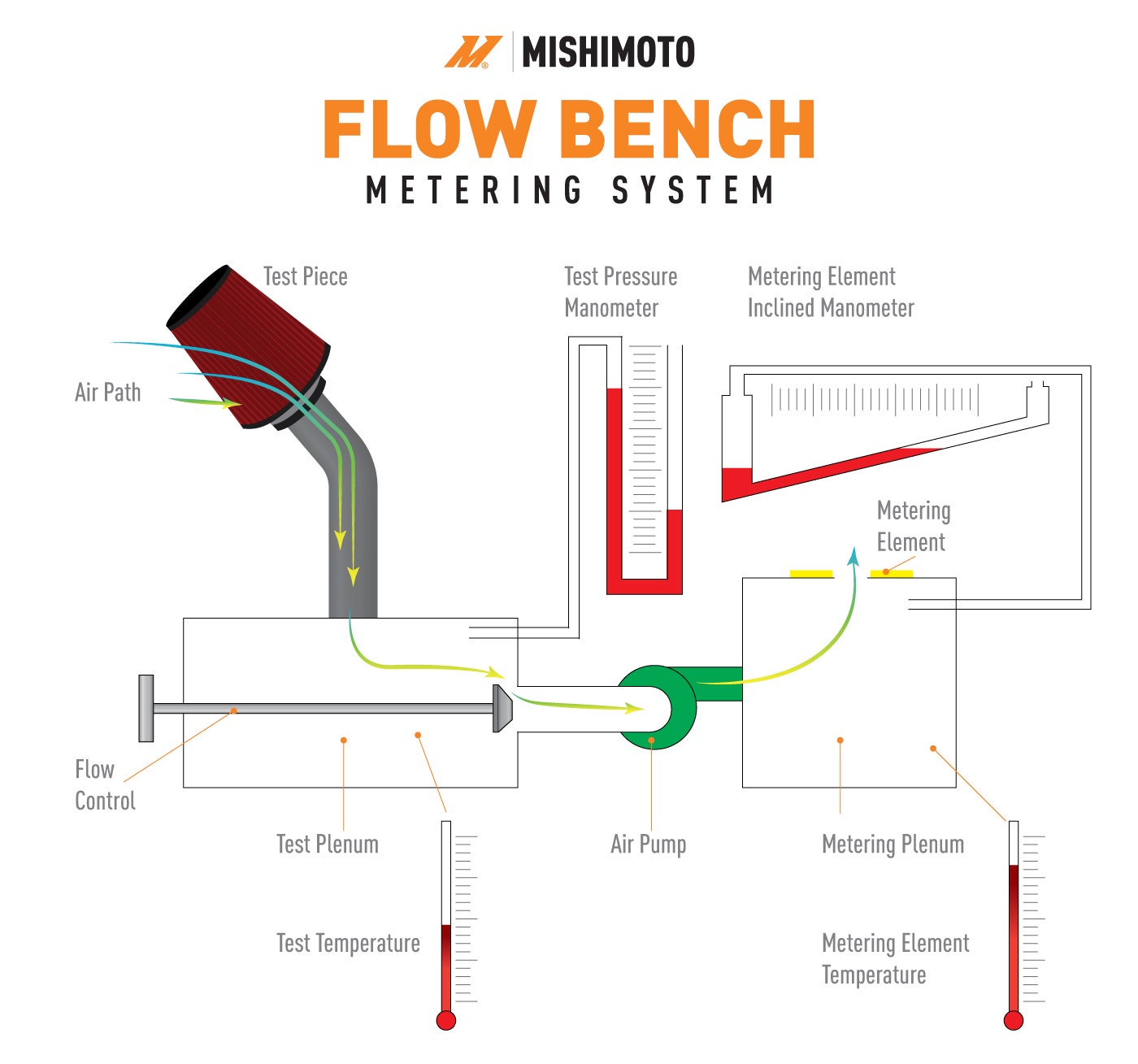

Dialing in specific flow rates is one thing, but gauging the effectiveness of our new designs is the real goal. Shown above is a general diagram of how a flow bench will meter different test perimeters. Still, this Superflow bench comes equipped with their proprietary FlowCom metering system, which combines the standard hardware with modern tech to compute testing results on the spot.

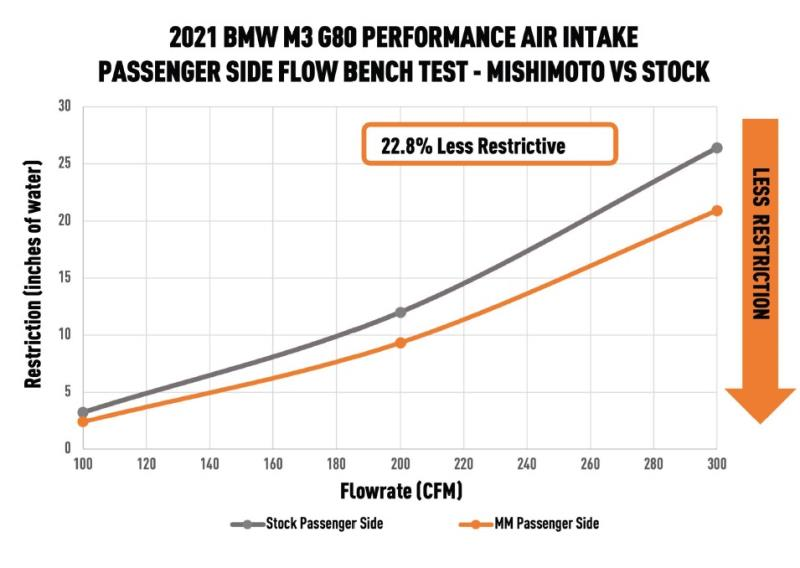

There's more to flow testing than blasting air through these components, though that is still involved. Basically, we're looking to determine how efficiently the air blasts through these components. So, we set up a specific testing procedure to ensure the best real-world results. In our testing, we input a target CFM value, otherwise changing the airflow to determine the total restriction of the component, which is measured as inH2O. Since the volumetric airflow rate will change at different RPMs and boost pressures, our engineers will test this component over a range of CFM values. They will then use the results to determine the restriction on both the stock component and our new design to create our flow data graphs:

When deciphering one of our flow graphs, there are a few important things to consider. First, what precisely is this restriction value. This number is a pressure drop figure which is the difference in pressure on either side of the component. The higher the pressure drop, the more restrictive the component is, leaving your engine gasping for air.

The second thing to keep in mind is that, in this case, less is more. The lower the final outputted pressure drop value, the more free-flowing the component is. Fewer obstacles and obstructions inhibit airflow through the component. So, since we're reducing restrictions, we aim to have a lower value than the stock component through our range of CFM values.

Every engine needs to breathe, and we're on a mission to make them breathe deeper. However, increasing an engine's lung capacity is a complex and intricate process that requires precision adjustments. Our Superflow Dynamics SF-1020 flow bench is the right tool for the job and is a crucial piece of equipment out on the shop floor. Make sure that you keep your eye out for our engineers measuring flow characteristics in our new products, and as always, let us know if you have any questions! Want to know more about our R&D equipment and processes? Let us know in the comments below.

Thanks for Reading!

-Nick