Whether you're hauling a heavy trailer through the mountains or crawling over rocks in 4WD low, your truck’s transmission is under constant stress—and that stress generates heat. Lots of it. Left unchecked, heat is one of the fastest ways to wear down a transmission. That’s where a transmission cooler steps in. So, what does a transmission cooler actually do, and why might it be time to consider replacing or upgrading one?

An automatic transmission operates by using hydraulic fluid to transfer power, control gear changes, and lubricate internal components. Every time your truck shifts, tows, climbs, or even just idles in traffic, that fluid heats up. Ideally, it stays within a temperature window around 175°F, but under heavy load, temps can climb fast—often past 225°F or even 250°F. That’s bad news for longevity.

A transmission cooler functions as a dedicated heat exchanger, just like your radiator or intercooler. It works by routing hot ATF (automatic transmission fluid) away from the transmission case and through a set of narrow tubes. Air passing over these tubes pulls away heat, cooling the fluid before it's sent back into the transmission. This closed-loop system helps regulate fluid temperature, keeping it in the safe zone and preventing thermal breakdown.

What Happens When a Transmission Overheats?

Heat is the silent killer of automatic transmissions. Once fluid temps rise above 220°F, it begins to oxidize—thickening, breaking down, and losing its lubricating properties. Internal seals harden, clutches glaze over, and metal parts wear prematurely. At 250°F, transmission life can be cut in half. Go higher, and you're risking complete failure.

That’s why even a factory transmission cooler may not be enough for truck owners pushing their rigs beyond stock use. If you’ve added bigger tires, bumped up power output, or use your truck for towing or off-road work, your ATF temps are likely spiking more than you think.

When to Replace or Upgrade Your Transmission Cooler

Like any heat exchanger, a transmission cooler can degrade over time. Fins bend. Tubes clog. Corrosion sets in, especially on trucks that see salty winter roads or river crossings. And in many cases, OEM coolers are built with basic materials and minimal surface area—just enough to get by for light-duty use.

If you’re noticing any of these signs, it might be time for a replacement:

• ATF temperature warnings or frequent overheating

• Sluggish or hard shifting during long drives or towing

• Discoloration or burnt smell in the transmission fluid

• Transmission failure or premature wear despite regular maintenance

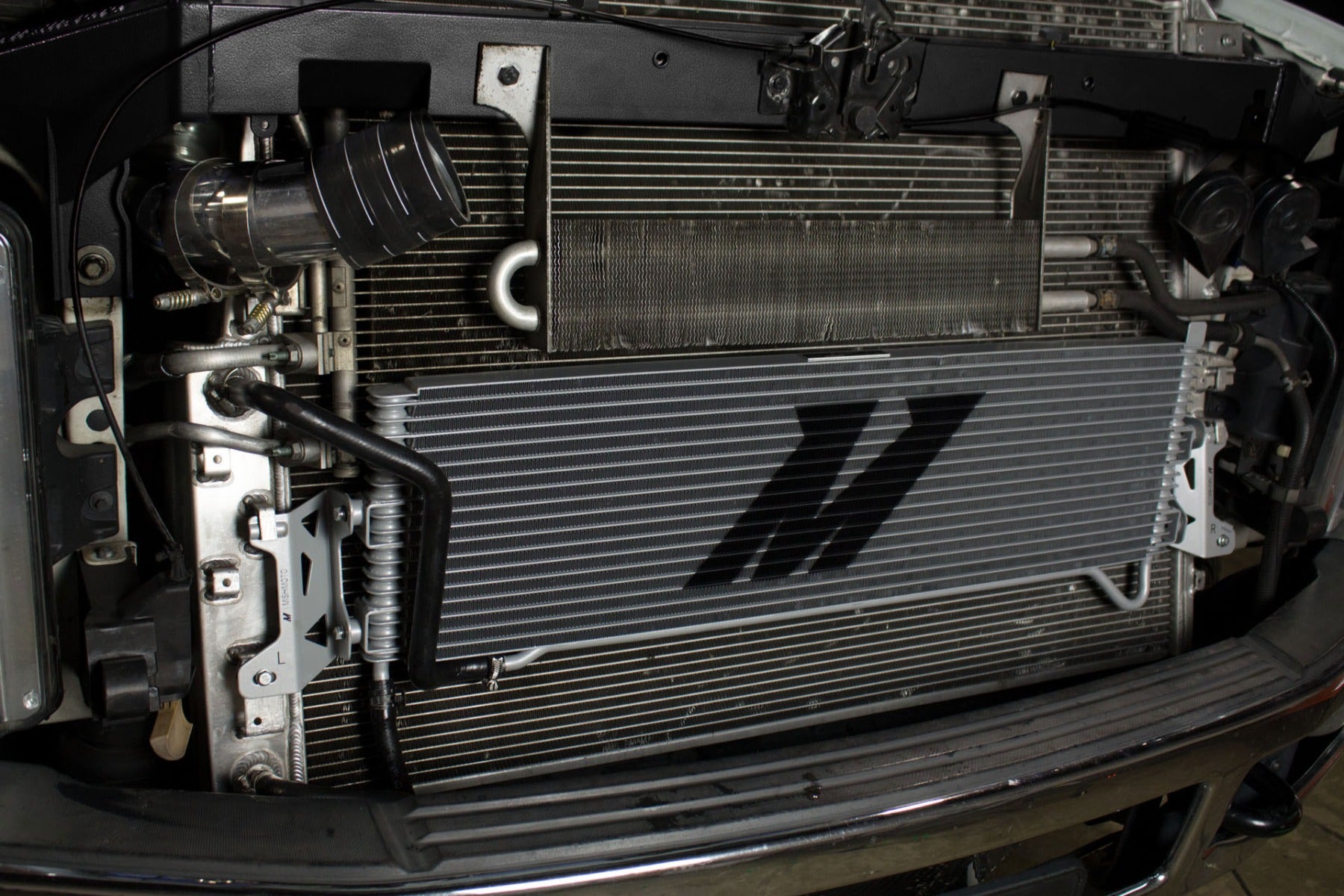

Upgrading to a performance transmission cooler is a smart move—especially for trucks that live in the right lane with a trailer behind them. Aftermarket coolers often feature more efficient designs, including larger cores, stacked-plate construction, and better airflow paths. These designs maximize surface area and thermal transfer, helping keep fluid temps low even when you’re pushing your truck to the limit.

Built for the Job

A transmission cooler upgrade isn’t worth much if it can’t stand up to real-world demands—and that’s where our experience designing coolers for some of the hardest-working trucks on the road sets this one apart. Whether it’s for a newer diesel towing rig or a classic gasoline truck for off-roading, our coolers are engineered to solve the same problem: heat. And we solve it by building systems that are more effective, more durable, and easier to install than the stock equipment they replace.

Our coolers feature rugged, high-efficiency cores that are engineered to outmatch stock designs in every measurable way. Whether using stacked-plate or tube-and-fin construction, each one is tailored to the vehicle’s specific cooling needs. That could mean improving core volume by over 500%, adding louvered external fins for maximum airflow, or integrating internal fins that maximize contact with fluid inside the cooler. Bench testing confirms what the numbers suggest: greater inlet-to-outlet temperature drops, lower peak temps, and reduced strain on the transmission under load.

But cooling capacity is just part of the equation. We also invest heavily in making sure these systems install cleanly and work seamlessly with factory components. That includes precision-machined fittings, quick-disconnect couplers, adjustable brackets for older chassis with variable mounting locations, and even relocation brackets for ambient air sensors and OE cooler lines.

We also work to create unique designs for each make and model for a tailor-fit application. For example, on the 2020–2022 6.7L Powerstroke, our engineers rotated and remounted the factory liquid-to-liquid cooler to work in tandem with our air-to-fluid unit, then designed dedicated CNC-machined isolation clamps and hard line routing to deliver bulletproof performance under extreme towing conditions.

The result is a lineup of transmission coolers that are ready to handle whatever the job demands. Whether you're towing at max capacity, pushing through mountain grades, or crawling off-road in high heat, these coolers are proven to keep temps in check and keep your transmission protected—mile after mile.

A quality transmission cooler isn’t just a luxury—it’s insurance for your drivetrain. Whether you’re trailering a boat to the lake or crawling up a steep grade with your lockers engaged, managing transmission heat is key to protecting your investment. If your truck is working harder than stock, your cooler should be too. Keep your ATF temperatures in check, and your transmission will thank you for miles to come.