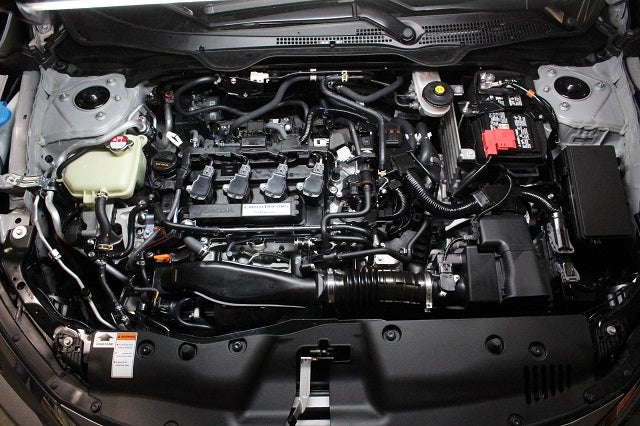

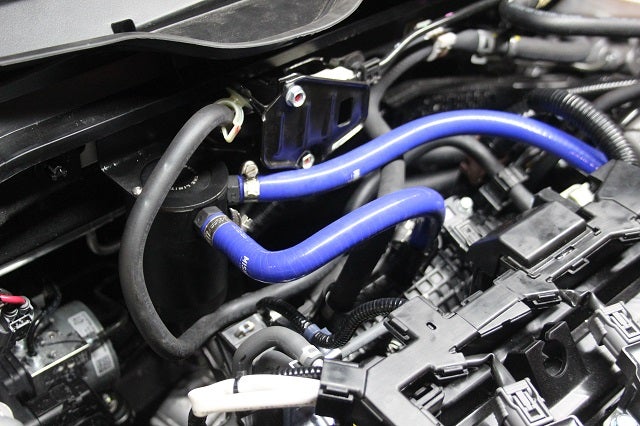

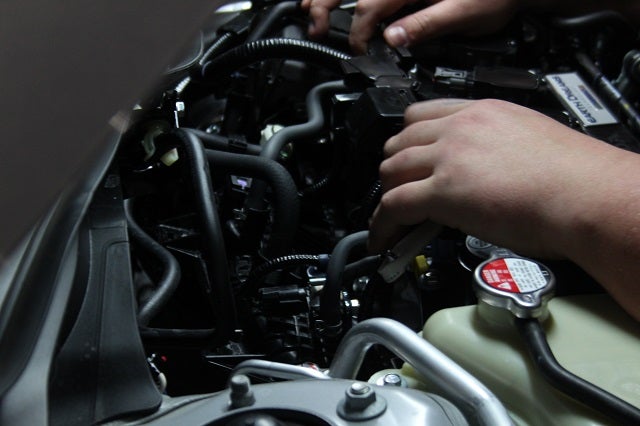

We have an update for our Focus ST intake project! Our first production sample has finally reached our R&D facility, and we have been able to test fit it onto a 2013 Ford Focus ST. Fitment was spot on, and we were able to get all the components properly snug into the car. We made some minor adjustments from our initial design and we included an awesome new feature that will help accommodate more Focus ST's on the road, so let's check it out!

It's the Little Things

During the time we were updating our design, we discovered small differences between the stock 2013"2015 and the 2016+ Focus ST intakes. The 2013"2015 Focus ST's have a screw type mass airflow (MAF) sensor that goes into the stock pipe. In the 2016+ model, however, the MAF sensor is replaced with an IAT sensor in the same location and it fits into a push-type clip housing. Many aftermarket intakes retain use of the stock accordion style boot that holds the sensor in place, " especially in

Subaru Forester XT performance parts up for testing

Subaru Forester XT performance parts up for testing