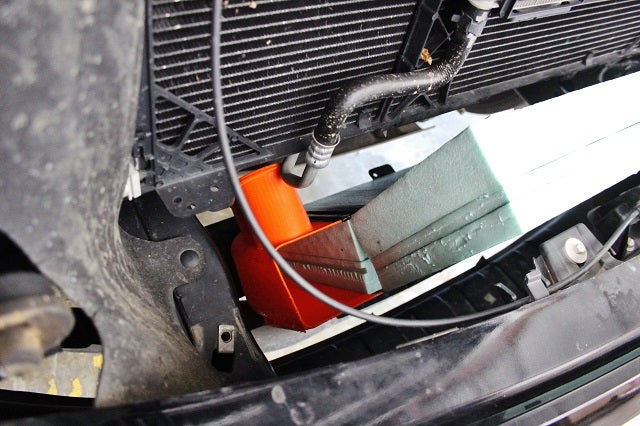

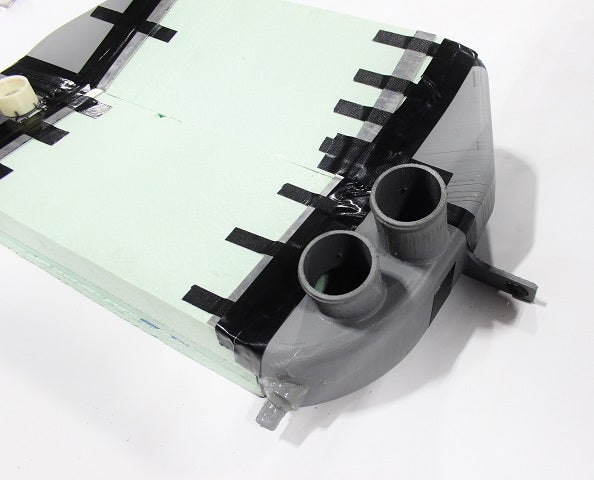

When we last had our test vehicle in the shop, the team fully evaluated the stock intercooler and piping system. In addition, we started to determine our projected core size and mocked up a foam prototype. In this segment, we will be expanding upon that by creating a mock-up prototype to test fitment.

3D-Printing Prototype

Using our mock-up foam core dimensions and data from the factory intercooler, our team began to construct the end tanks using 3D-modeling software. To confirm fitment, each section was 3D printed to create a prototype that could be placed in the vehicle.

This process required some trial and error to ensure that the 3D model was as accurate as possible. The inlet/outlet portions were the most challenging, so these were printed and tested first.