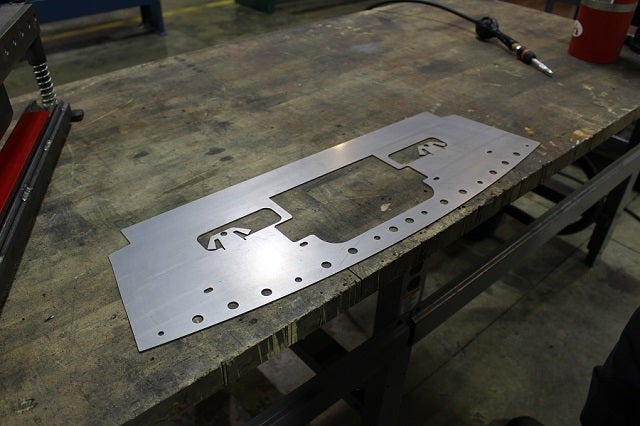

In our last post we took a look at our plans for the Mustang radiator and how we were designing it in Solidworks. Thanks to the speedy design, our first functional prototype is complete and ready for some test fitment!

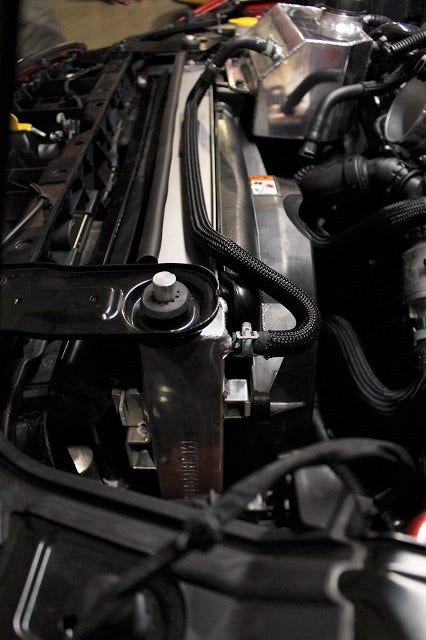

Straight out of the box, it is quite a hefty unit and should provide some much needed cooling for this GT. Check out some installed photos of our functional prototype.

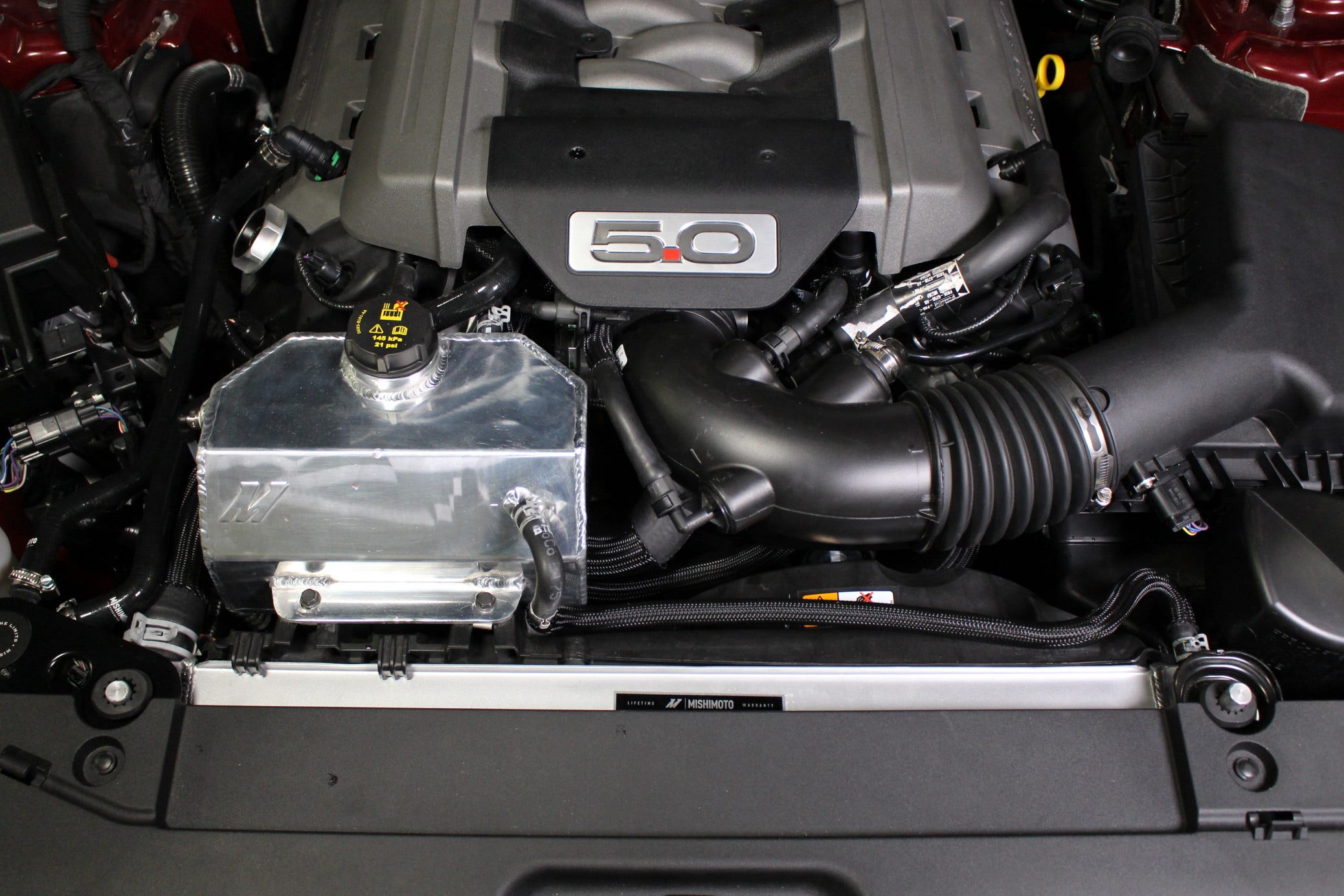

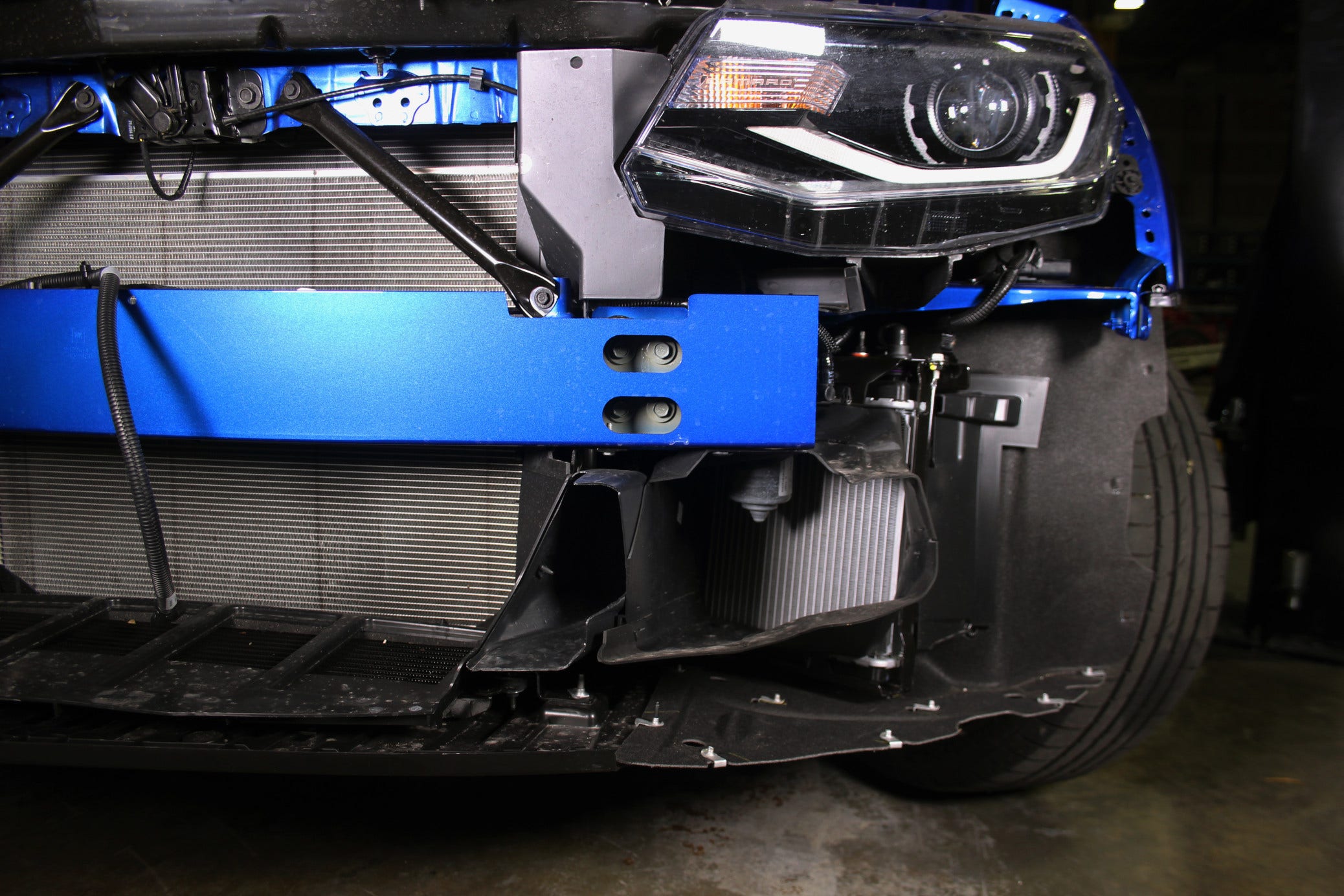

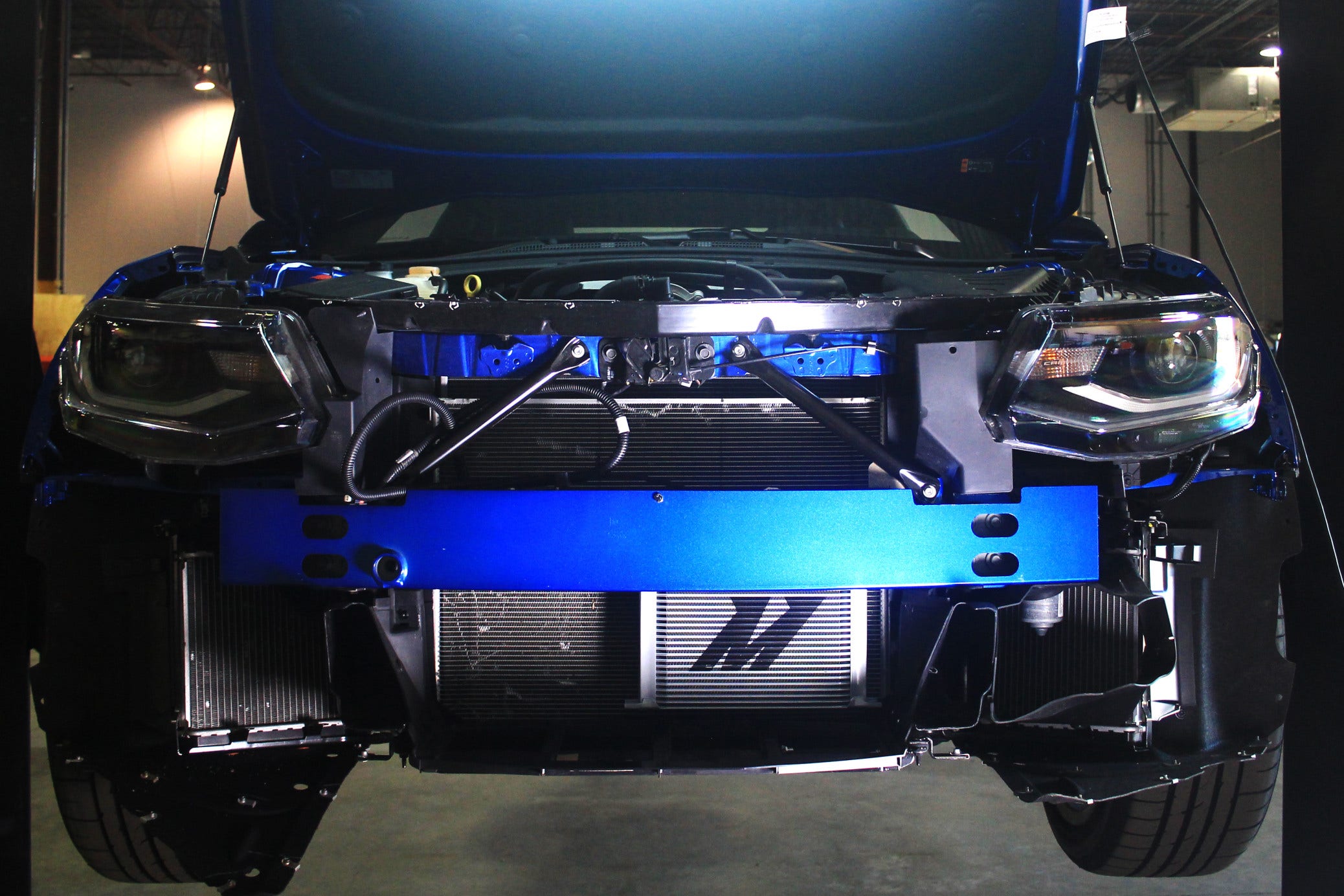

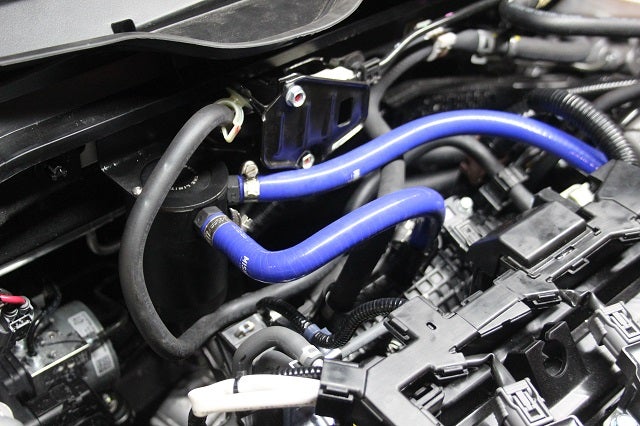

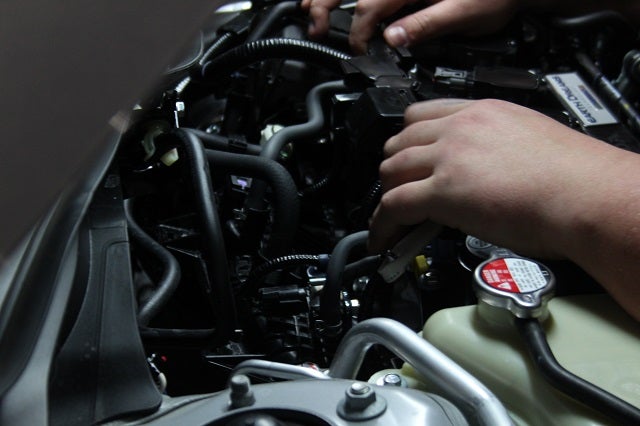

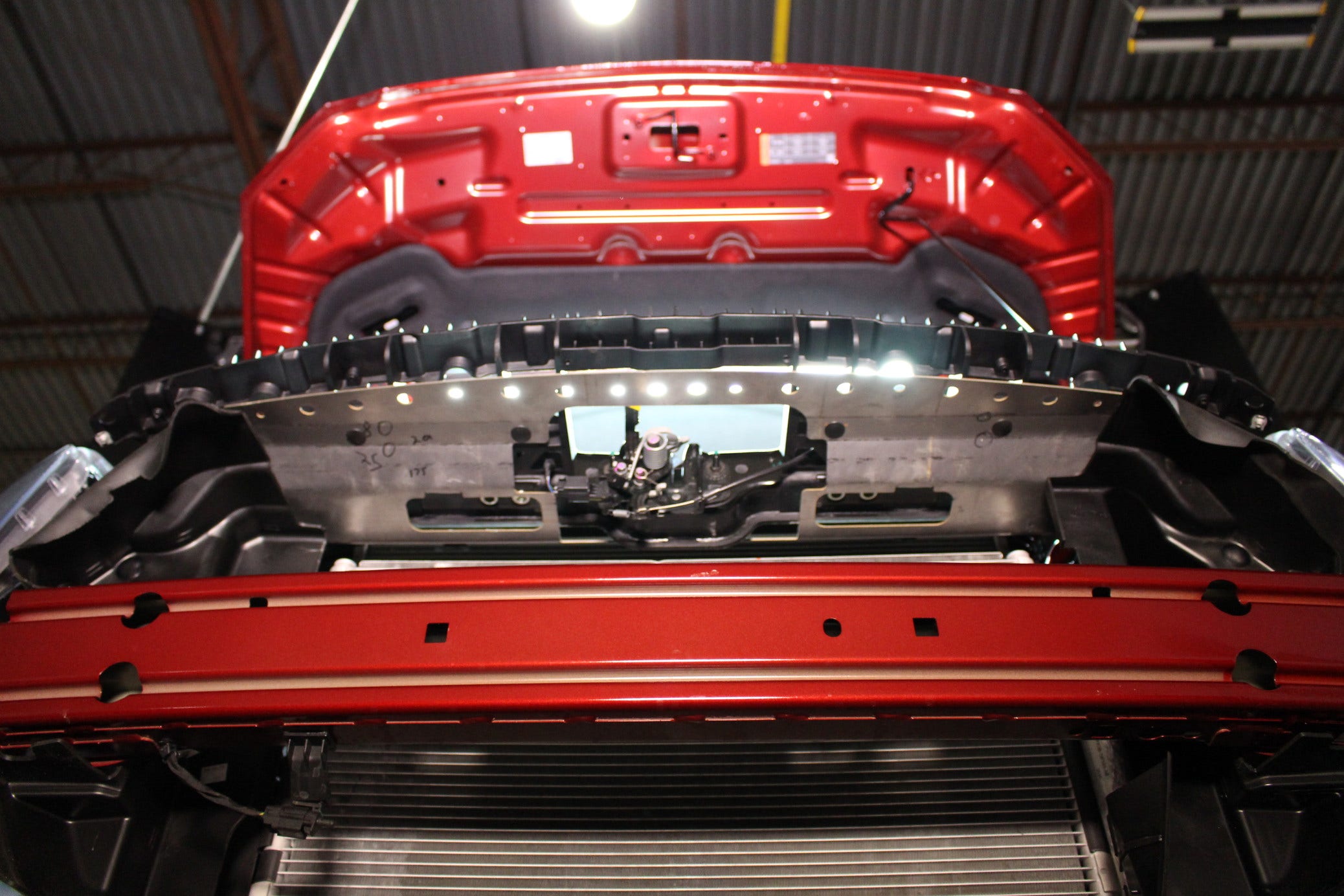

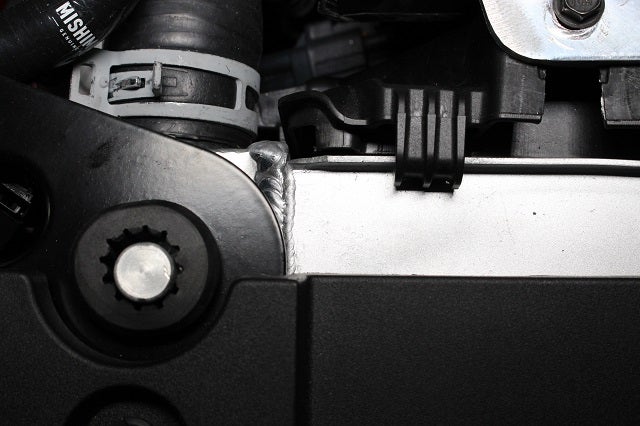

Mustang radiator installed

Mustang radiator installed