The most exciting part of product R&D is always the testing phase. This typically includes setting up some neat sensors, running the car on the dyno or on the street, and crunching our data. We are anxious to see how our first prototype coolers perform on the Fiesta. Let's jump right into the plans for this first round of testing.

Testing Plans

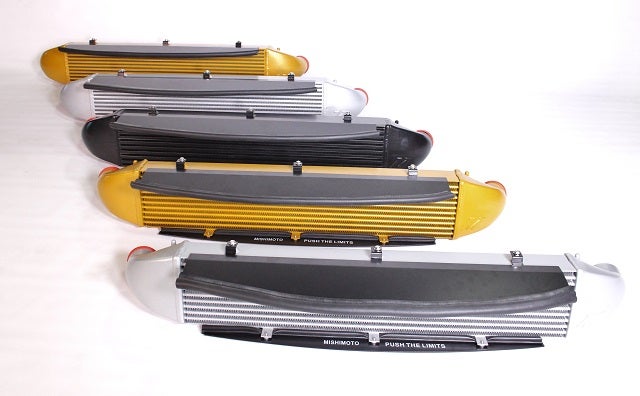

As mentioned in the previous segment, we will test four different coolers.

- Stock intercooler

- Mishimoto bar-and-plate prototype 1 (larger internal bar height)

- Mishimoto bar-and-plate prototype 2 (smaller internal bar height)

- Mishimoto tube-and-fin prototype

For each cooler we will be collecting data for temperature, pressure, and power output. Each cooler will be tested repeatedly until we have three consistent runs producing data as accurate as possible.

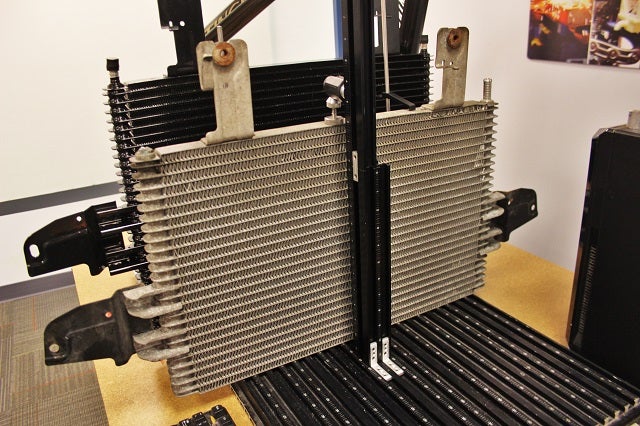

Below is a look at the three different core types that will be tested.

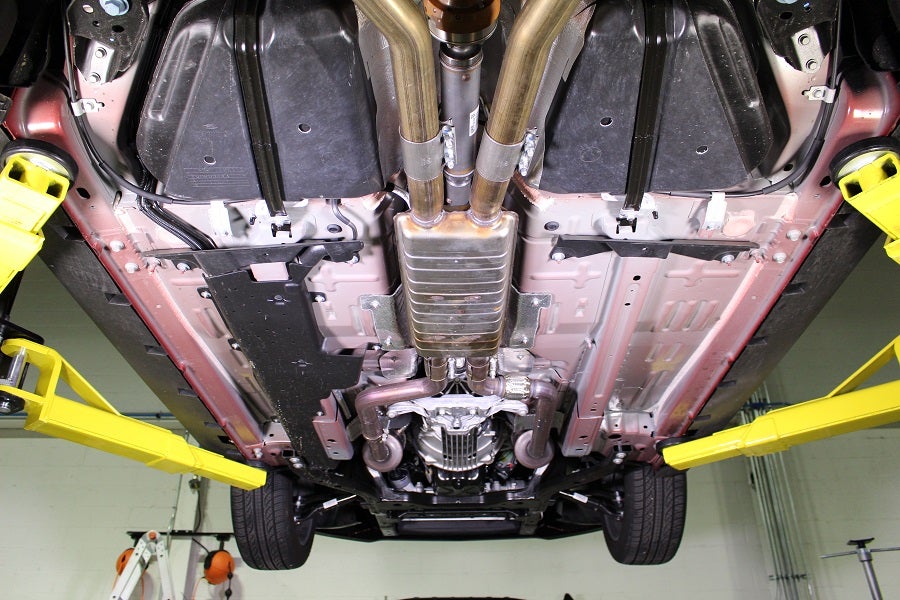

Stock Mustang GT exhaust

Stock Mustang GT exhaust Stock Mustang GT exhaust

Stock Mustang GT exhaust