Last time we wrapped up our resonator-delete testing, and with that component good to go, we're on to our next conquest, axleback exhausts. If you have not had a chance to take a look at our resonator deletes check out our blog posts HERE.

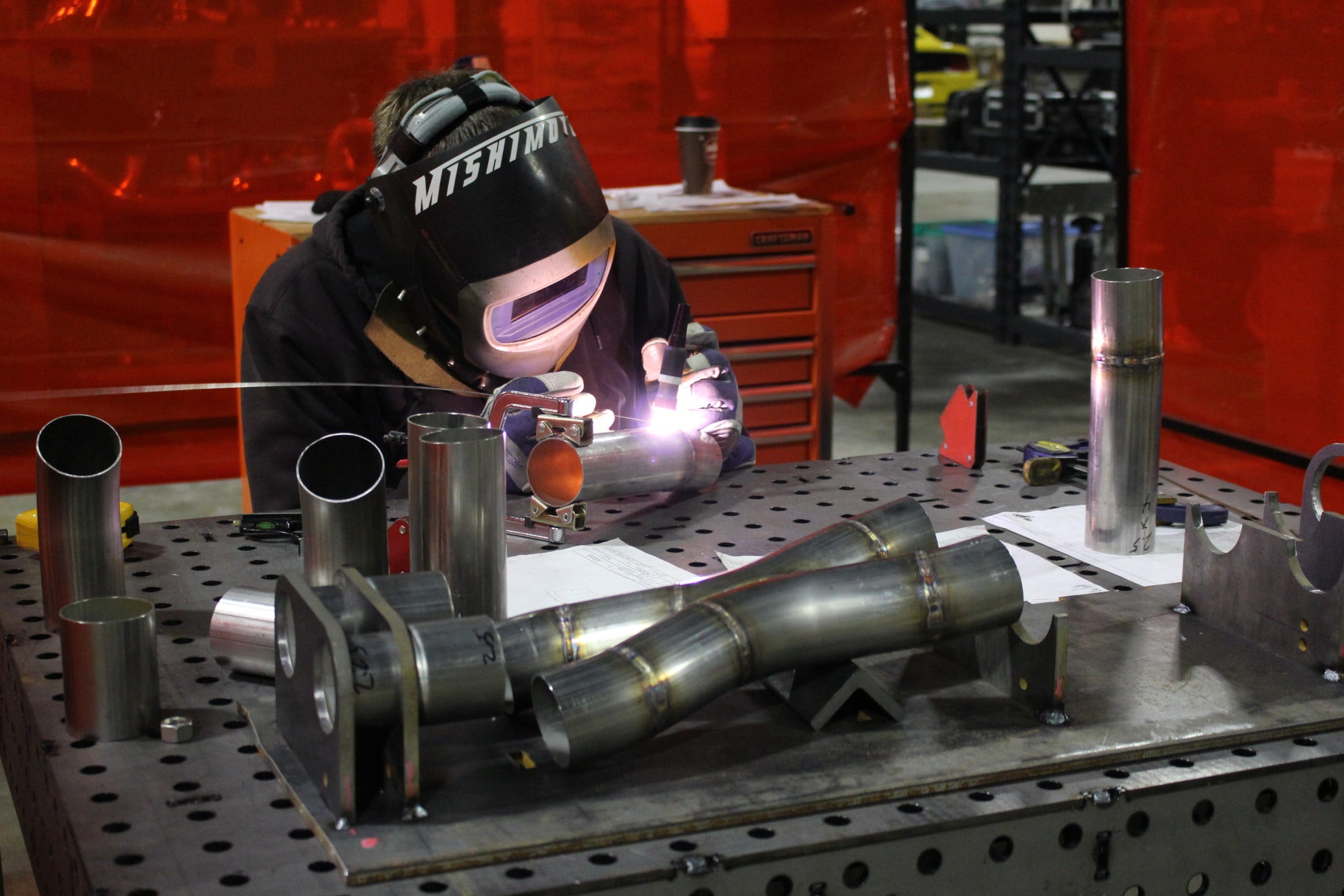

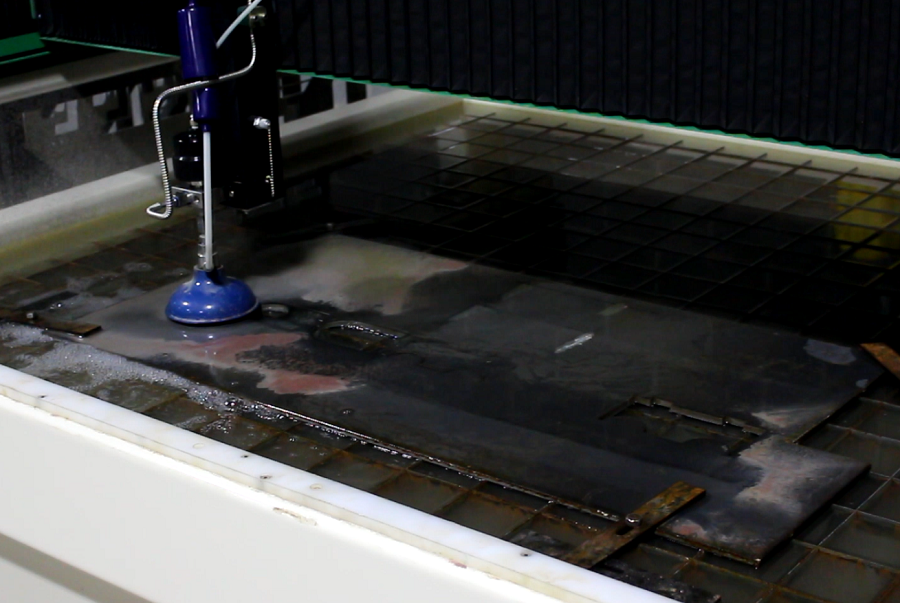

Axleback Fabrication

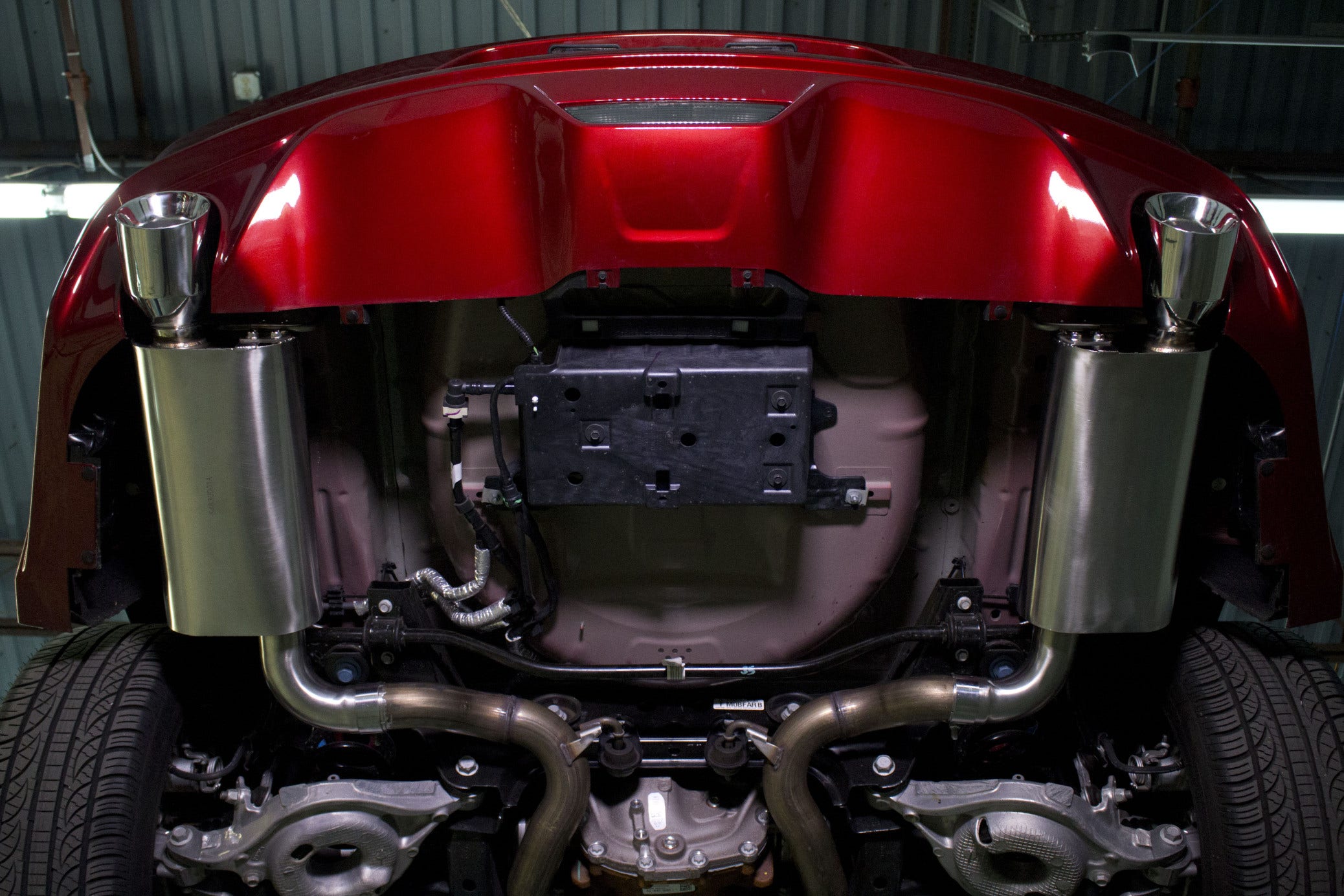

Any living, breathing car enthusiast knows that the exhaust is an important modification for modern muscle. Most owners want to rid themselves of the stock sound and let their pony car be heard right out of the gate. Being s550 owners ourselves, we want to hear the unrestricted growl of the Coyote in our GT, so we set out to design some axlebacks. We intend to design a few options as we want to offer an exhaust for every taste. We plan to test a straight-pipe option for those who want to hear the GT scream, a small-muffler option for those who want an aggressive note but have neighbors, and a large-muffler option for those who like

" width="900" height="603">

" width="900" height="603">

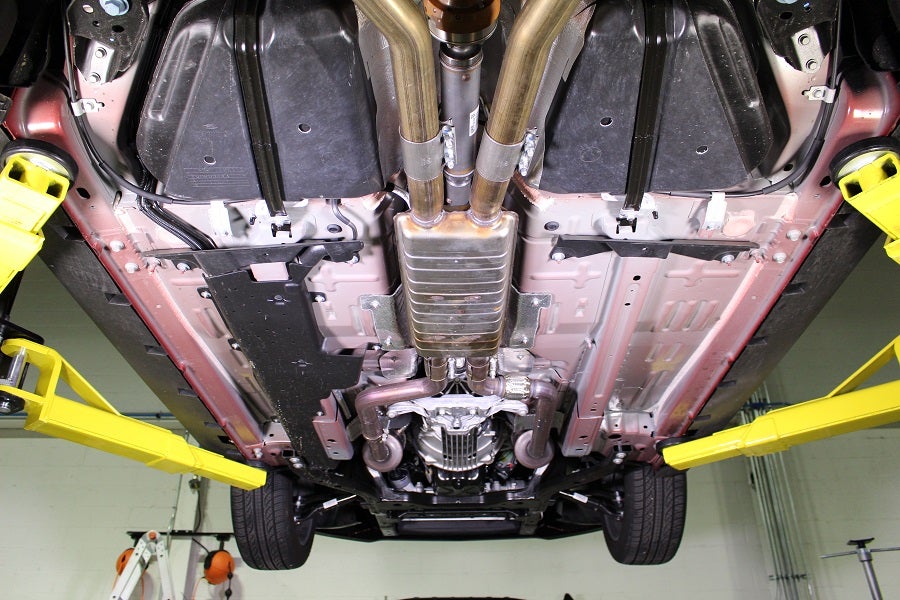

Stock Mustang GT exhaust

Stock Mustang GT exhaust Stock Mustang GT exhaust

Stock Mustang GT exhaust