Transmission Cooling to the duraMAX - 2001-2010 Chevy /GMC Duramax Transmission Cooler, Part 1 - Stock Review

Extreme heat is always the enemy, especially when it comes to vehicles equipped with an automatic transmission. The Allison gearbox mated with your 6.6L Duramax is no exception. With the high temperatures produced by an automatic transmission, it seems almost cruel that the sweltering summer heat comes when most of the towing of campers, boats, and other outdoor toys happens. GM did include some help to keep your gears cool. Unfortunately, it's a little small.

For such an iconic towing machine, it seems strange to equip it with such a small transmission cooler.

While the 9 rows on the factory cooler keep the transmission cool enough during regular driving, it shows its limited cooling abilities once a few thousand pounds are attached to the rear of the truck.

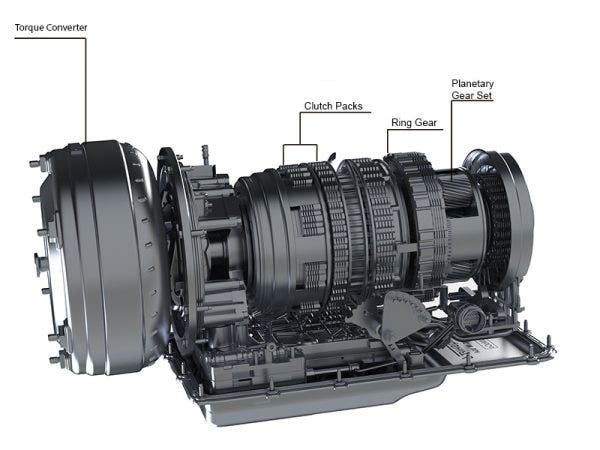

Before we start with the adorably small transmission cooler on the GM Duramax, some of you might be wondering why this extra heat exchanger is mounted on the front of your truck to begin with. Like your own body, the heart and soul of your Duramax operates best at a specific temperature. As you sit and read this, your body is functioning at optimal capacity while hovering right around 98°F. On average, the automatic transmission in your vehicle will be shifting through gears the smoothest between 160-180°F. All that heat is being produced from friction caused by components slipping, pressing, and syncing together. A big portion of heat comes from the constant churning and compression of the fluid in the torque converter, on top of the slippage rates of the clutch packs.

Labeled are the main culprits for the heat produced inside of your transmission housing. To put it simply, your ATF keeps the hundreds of moving parts lubricated, and extreme heat can diminish the lubrication properties of the fluid, hence the importance of keep it within the recommended temperature parameters.

Much like when your internal temperature spikes, as the operating temperature of your Allison transmission begins to increase, problems begin to surface. Think of it like your transmission having a fever. While most automatic transmission fluid, or ATF, is rated as being able to handle temperatures over 300°F, running at that temperature can shorten the fluid's lifespan to just a few hundred miles. Remember all of that slipping, pressing, and synchronization? The fluid in your transmission is a lubricant which makes sure everything can move smoothly. However, the heat oxidizes the fluid, and as the temperature increases, less lubrication reaches the hundreds of components inside the housing, which will lead to burnt ATF, or worst case, a totaled transmission.

Most major brands manufacture their automatic transmission fluids up to the standards of the GM Dexron blend as well as other manufacturer's recommended tolerances.

This is something that all car manufacturers take into consideration during the engineering process, and equip safeguards for what is effectively the second most important component on your vehicle. For starters, this is the reason for the cooler in the first place. As part of the lubrication cycle, fluid is sent through the lines to the heat exchanger for extra cooling before making sure all your gear changes are as smooth as possible. Since the Duramax trucks are designed for heavy lifting, GM specifically engineered their ATF to operate at temperatures up to 200°F. As a final safeguard, most manufacturers, including GM, incorporate what is commonly referred to as, "Limp Mode," which limits your gearing, allowing you to pull over and cool down. This might seem like a practical way to keep your transmission intact, but it could end a track day before it even starts if you spend most of your time on the shoulder.

To put it simply, the automatic transmission mated to your Duramax is a complex piece of machinery that needs some extra help to keep it cool. One of the best ways to keep your transmission operating at the optimal temperature, other than being able to control the weather, is by way of a transmission cooler, another useful feature that GM included to keep your Silverado and Sierra running and towing efficiently. However, as mentioned before, on the 2001-2005 models the heat exchanger seems a bit undersized, and in most cases, can't keep up with cooling the transmission while under a heavy load and in high ambient temperatures.

On the 2001-2005 models the cooler is mounted directly in front of the AC condenser, meaning it receives the proper airflow, however the size of the cooler still restricts it's ability to cool the transmission fluid.

While the size of the cooler increased with the styling refresh in 2006, the engineers at GM tucked it behind the bumper which limits the airflow to the heat exchanger.

From 2006-2010, GM must have realized their blunder of equipping one of their best-selling towing machines with such a small transmission cooler, and increased the width and surface area of the cooler, but tucked it underneath the bumper and limited the airflow. While there are a few tricks to give the newer cooler extra air, including flipping it on its axis, or bumper and shrouding modifications, there's still that elephant in the room"it's too small.

For comparison, here's a photo of the two options for the transmission cooler from the 6.0L Ford Powerstroke in the same year range as our loaner Silverado 2500HD. Their base option included a 26-row cooler, with the option to bump up to a 31 row.

The transmission coolers from the similarly aged Ford Powerstroke 6.0L. Ford equipped their diesel powered towing machine with a 26-row cooler and had an optional 31-row upgrade from the factory.

Moving over to our GM cooler, we're faced with less than half of the rows and a fraction of the surface area. How is your Chevy supposed to out-tow its Ford counterpart without the right transmission cooling?

Only 9 rows to compete with Ford's 26-31 rows.

Steve used out Faro Design ScanArm to create a 3D model for the front of our loaner 2500HD in order to easily determine a build envelope for the new and improved cooler

The size is exactly what we intend to correct. It's not always true, but in this case, bigger is better. After using the Faro Design ScanArm to model the front of our loaner, we can get to work on determining just how big we can make the new cooler. Our engineer, Steve has been pouring over data on his computer this week, sizing up the options as we continue to design a way to have your Allison transmissions from 2001-2010 properly cooled.

Thanks for Reading!

-Nick