Getting Into The Thick of It - Intercooler R&D, Part 3: Running Numbers

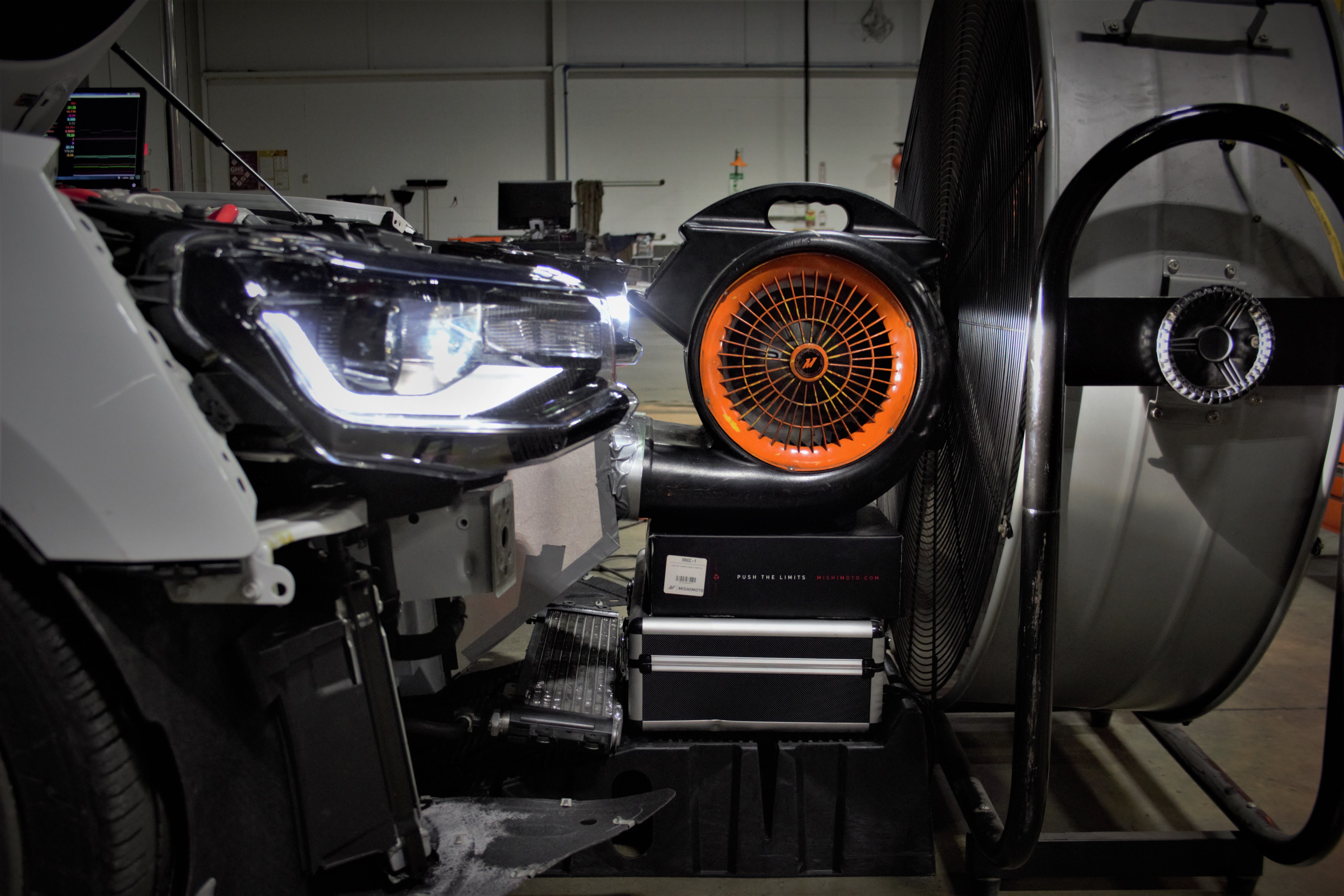

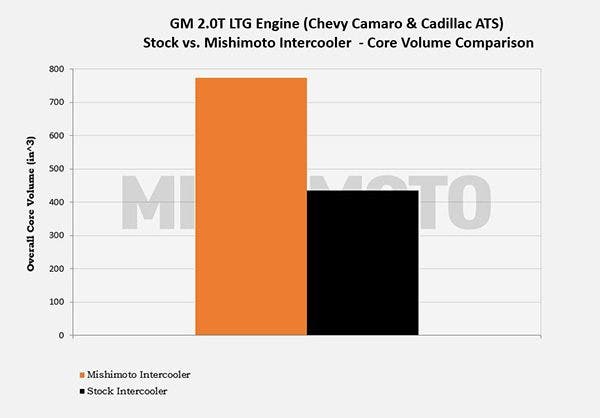

Our engineering department sought to bombard our intercooler with dyno runs, gathering as much data as possible to ensure that it could stand up to the abuse and intensity you plan to put it through. Due to the fact that this intercooler is sandwiched between the radiator and air conditioning condenser, we had to be sure that our core could effectively combat the effects of heat-soak while performing at maximum efficiency. First, we had to start with size. If the intercooler was going to be an effective modification, it had to be bigger. In case you guys need a refresher from our last update, see below for a size comparison between our core and the factory unit.

Core volume comparison

External fin surface area comparison

We have given the core a boost in several areas, including internal volume by 45%, external fin surface area by a sizeable 239%, and overall core size by 78%. This will allow for much better cooling and heat transfer. While the core is bigger than stock, it will also be a direct fit to another application besides the 2.0T. This core is also a direct fit for the 2013+ Cadillac ATS 2.0T, so the size benefits can be enjoyed across two different chassis!

Heat-soak was also something we had to pay close attention to, so we strapped our shop 2016 Camaro 2.0T to our Dynapack, and beat on the engine to see how we could improve temperatures through the core. The test consisted of at least five complete runs, with about a minute of idle in between. This allowed the intercooler to really heat soak with little breaks. We recorded temperatures on the very last run and compared stock numbers to our intercooler.

Results of the first heat-soak test

As you can see, we achieved a maximum temperature drop of 25˚ when comparing the stock and Mishimoto outlet temperatures through the stock outlet pipes. This is a substantial drop considering how heat-soaked the system was. The second test was louder to say the least. With the Camaro on the dyno, we let the 2.0T rev at wide open throttle around 4,000 RPM while the Dynapack loaded the run, forcing the engine to stay in high boost. We held it in these conditions for about 10 seconds to let the turbocharger work overtime and force boost.

Results of the second heat soak test

We had maximum temperature drops of around 61˚. Our outlet temps stayed at a constant level, while stock outlet temperatures kept rising, proving that our design is much more efficient and capable of rejecting heat.

Still not convinced? Check out the GIF images below. On the left is a heat-soaked dyno run, with the stock intercooler, and on the right, is a heat-soaked run with our intercooler.

The images show how well this intercooler reduces outlet temperatures. The entire stock unit gets hot, taking in some of the engine heat all the way to the outlet pipes and, feeding the engine air that's hotter than it needs to be. It also allows heat to concentrate in one area as it begins to spread around the core. Our core gets hot at in the inlet, but the airflow is immediately cooled through the rest of the core. Using computational fluid dynamics to analyze the end tanks, we added internal diverters to evenly distribute the heat and put the entire core to work. You can see proof-of-concept in the GIF comparison as the heat distributes evenly throughout the entirety of the core's height.

Note that the purpose of heat soaking is to get the performance numbers when the car is being run on the more extreme, heavy duty end of the spectrum, like doing back-to-back passes at your local drag strip, or attempting to set quicker lap times during autocross. Doing these tests while the car is cold would show that the stock setup cools adequately, however you and I both know that with this intercooler, you don't plan to go easy on your LTG, which is good considering what our intercooler does for horsepower performance.

Horsepower and torque curves for our intercooler

Our core bumped performance with gains of 15hp and 12 ft-lbs of torque - right out of the box, no other modifications, tunes or bolt on parts. That is a great power increase for an intercooler, showing that the stock unit just won't cut it if you want to make more power with other supporting modifications.

Thanks for reading. Keep an eye out for the upcoming presale!

-Diamaan