Mishimoto 2011+ Chevrolet/GMC 6.6L LML Duramax Performance Intercooler, Part 6: Final Results and Product Conclusion

Interested in purchasing this Duramax Intercooler? Check out our product page for more information!

Mishimoto Chevrolet/GMC 6.6L Duramax Intercooler Kit

With our testing complete, it was time to recap the results and see what kind of benefits our cooler was capable of producing. The testing procedures and information from our previous posts are outlined below.

Testing Procedures and Information

Vehicle: 2011 Chevrolet 2500 6.6L LML Duramax

Engine Modifications: None, all factory equipped

Ambient Temperature: 85°F (29.5°C)

Humidity: 35%

Sensors: PLX Pressure and temperature sensors were placed on both the hot-side and cold-side intercooler boots.

Physical Benefits

Before we jump right into the testing data, let's compare the physical aspects of our intercooler design that distinguish our unit from the factory cooler. We increased the core size of this cooler significantly, so let's take a look at the actual numbers behind the increase.

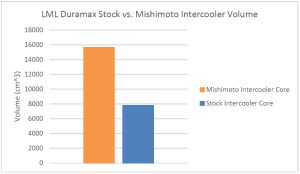

Comparison chart of intercooler volumes

The gains in size are huge. We increased the core thickness by 73%, resulting in a core volume increase of 101%! The additional volume will allow our cooler to support vehicles with higher power output that generate greater heat within the CAC system.

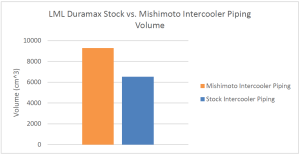

Next, we compiled data related to the volume of the intercooler piping we developed for this truck. You saw it sneaking into a few of the images from our last post. Check out a volume comparison of the piping we designed.

Comparison chart of intercooler piping volume

We've managed to increase internal volume by a staggering 42%. You may be wondering why we would want to do this. Our team does not simply enlarge every product we create; each design is evaluated to provide optimal performance for a specific need. In theory, a larger volume would require greater time to fill, potentially resulting in increased lag or pressure drop. On the other hand, for modified vehicles, small piping can restrict flow and reduce maximum power output. Our goal here is to find a sweet spot where lag is not increased, yet the overall flow provides support for modified trucks. If our math is right (it always is!), we certainly achieved this.

Power Output Data

The composition of fins and bars is an important consideration when developing an intercooler. Ideally we want to cram as many fins into the core as possible. The external fins provide heat-transfer contact points, which facilitate the heat transfer from the internal air to the external air. We also have to consider the space for the bars. Too many fins (or rows of fins) could affect the size of the intercooler bars. Bars that are too small could restrict flow throughout the core and have a negative impact on performance. Although we like to put a ton of math and science behind our product designs, sometimes real-world testing is more accurate and informative.

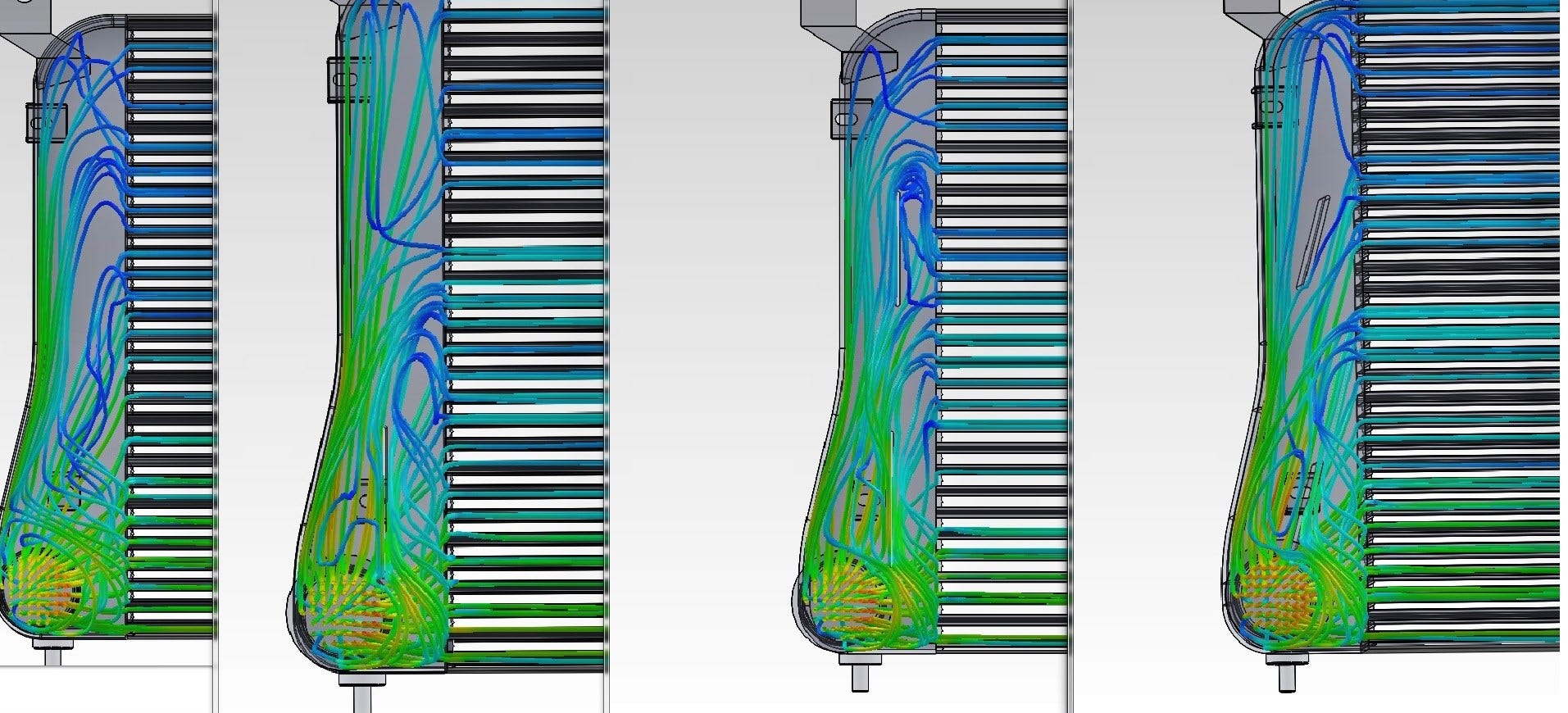

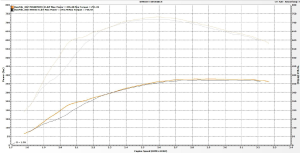

For this test, we decided to try out two different core designs. After making numerous dyno pulls with each, it was clear that one core outperformed the other in power output, as well as showing a slight improvement with temperature reduction. Check out the dyno plot below for the core we selected to move forward on this project!

Dyno plot of Mishimoto 2011+ Duramax intercooler

An intercooler typically does not add power. Rather, it is a supporting product for vehicles with other modifications. That being said, we are normally able to squeeze out a few ponies with our designs. In this case, we were able to provide maximum gains of 7 whp and 15 wtq. Additionally, our cooler makes greater power across the entire powerband. The initial gains you see prior to 2,200 rpm are a result of our throttle application during the test; this has been excluded from our posted gains. So in the power department, we saw quite a nice increase for a factory truck, and we expect similar if not better gains for a modified truck.

CAC Temperature Benefits

Air temperature reduction is the primary goal for any intercooler our team develops. With modern diesel trucks, the factory cooler is rather efficient in temperature reduction. We found that the outlet temperatures for the factory cooler and the Mishimoto unit were nearly identical during each test, dropping temperatures to around 10 degrees (F) above ambient. Keep in mind, this is a factory truck tested in fairly mild conditions without any appreciable load. Our team is confident that this cooler will provide ideal temperatures during towing, hauling, or through extreme weather. Additionally, our cooler will provide optimal performance for modified trucks that produce higher temperatures. Ideally we would perform a similar test during a longer drive with some form of bed load or trailer load to see the effect on temperatures. With additional engine load comes additional heat, which is guaranteed to affect inlet temperatures and truly test the efficiency of a heat exchanger. In the future we hope to have a vehicle available in a warmer climate, with some form of load to complete a more relevant test for those who use their trucks for towing/hauling on a regular basis. We have already spoken with a few truck owners; if you are local to Delaware and interested in such a test, please contact us!

As of right now, we are confident in our product and will be releasing it soon! Our overall design and physical benefits provide enough evidence that we can support our intended customers.

With our testing complete, let's review our goals and put a close on this project.

Project Goal Recap

- Intercooler must be a direct fit and require no vehicle modification.

Check! We designed this cooler to fit into the LML Duramax without modification. Additionally, we designed this cooler in conjunction with our aluminum radiator to ensure that it functions and fits with the Mishimoto radiator as well as the factory radiator. This intercooler fits into position just like the factory unit, making for an easy installation process.

- Intercooler volume must be increased.

We increased core thickness by 73%, which resulted in an overall core volume increase of 101%. Yes, that's right, we doubled the core capacity of the factory intercooler. Our team was able to achieve this while still providing drop-in fitment for the LML.

- Design a core dense enough for optimal heat transfer.

Our team used a combination of equations and real-world testing to design a core that would provide both optimal flow and ideal heat transfer. Our product is applicable for factory vehicles, and will also support modified vehicles with higher power and torque output.

- Fully test the product to reveal improvements and benefits.

We performed a great deal of testing to ensure that our product provides the performance our customers demand. Despite the physical and power benefits of our cooler, we would still like to conduct some additional temperature testing in a more demanding environment to show the benefits of this cooler for trucks operating with higher loads.

Thanks again for following along with the progress of this build! Feel free to follow up with any specific questions you have about this project, or any of the other components we offer for the Duramax!