Mishimoto Ford 6.0L Powerstroke Coolant Filter Kit, Part 2: Initial Design Prototypes

Interested in purchasing this Coolant Filter Kit? Check out our product page for more information!

Mishimoto Ford 6.0L Powerstroke Coolant Filter Kit

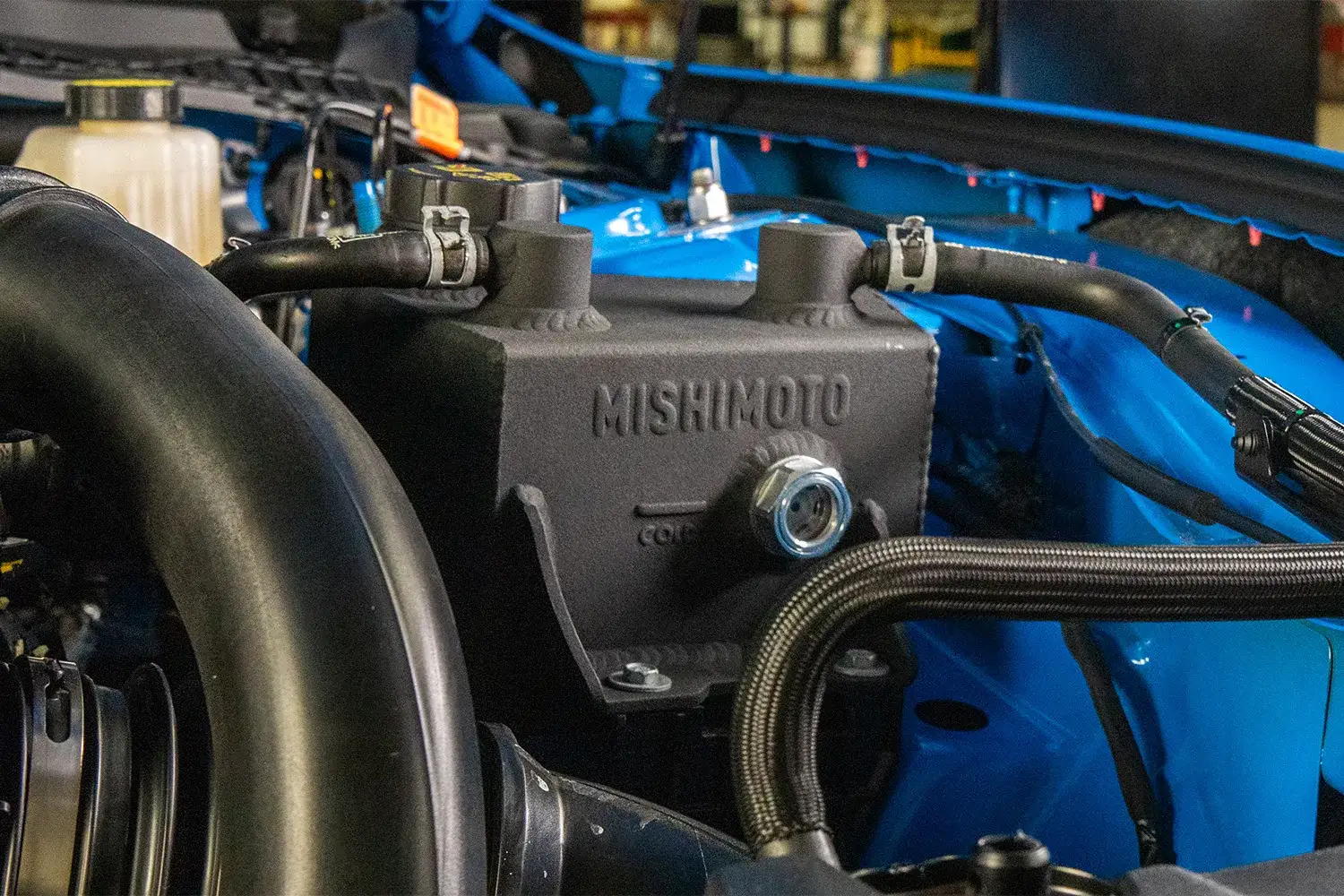

Coolant Filter Housing Prototype

Time for some CNC-machined goodies! Last time we left you with a look at our 3D-printed prototype housing. After reviewing the design and making some minor adjustments, we were able to create a CNC-machined aluminum housing. Check out the results below!

3D prototype housing (right) and CNC-machined housing

And a few close-up shots!

CNC-machined coolant filter housing

CNC-machined coolant filter housing

So let's chat about some of the features you see on this housing. First, this component is constructed from billet aluminum and machined into the proper shape. The inlet and outlet ports are both machined and threaded to accept the valves that we will discuss soon. We then use a threaded filter adapter on the base, which accepts the filter we have selected to use for this project.

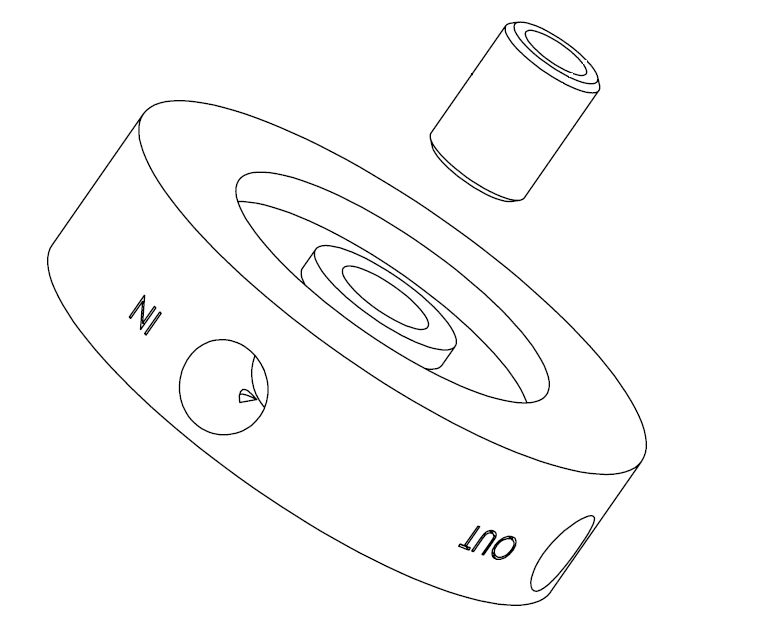

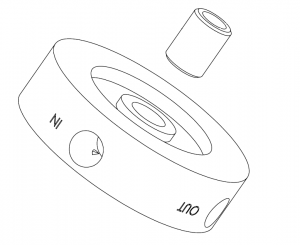

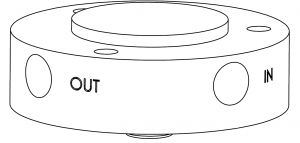

The top of this unit features a cylindrical bracket mount that is completely adjustable. Our team is always looking to the future during product design, so we decided to create a housing that could be incorporated into numerous coolant filtration kits, not just for the 6.0L. In fact, we already saw a need for a kit specific to the 6.4L, so development has begun to fulfill that need. We also use subtle silkscreen logos on the top of the housing as well as on the ports to identify which hose connects to each position. This is a really nice piece, and we are extremely pleased with the overall design, as well as the aesthetics. Check out a couple neat shots of this housing from our Solidworks drawing.

Mishimoto coolant filtration kit housing drawing

Mishimoto coolant filtration kit housing drawing

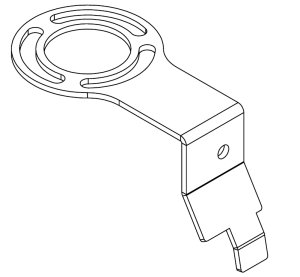

Bracket Fabrication and Prototype

Our next task was to develop a bracket specific to the 6.0L chassis, which would mount our coolant filtration housing in the engine bay. Our goal was to select a location that would provide easy servicing of the filter, while not impeding any other engine bay components. Additionally we would be looking for existing mounting points we could use. After evaluating the engine bay, our team decided upon a location near the radiator support on the passenger side of the vehicle. We then fabricated a bracket that would provide stabilization of the filter and housing. Check out what we came up with!

Fabricated housing bracket

The process by which we create these brackets is quite interesting. Our engineers take all the necessary measurements from the engine bay and our housing, and then they convert them to create a 3D model of the part. This part is then "flat packed," which means it is placed on a flat plane, while identifying the bends and holes needed to make the part. We can then glue this paper printout to a flat sheet of material and make the necessary bends and cuts. It is a pretty slick process that removes a ton of guesswork out of product fabrication, making our process quick and accurate. Once we confirmed the fitment of our fabricated unit on a test vehicle, a real prototype was worked up.

Fabricated housing bracket (left) and prototype bracket (right)

As you can see above, the bracket design changed slightly through the prototyping process. Initially we were using a three-hole bolt-on design. This was later adjusted to a slotted mounting location that could swivel around a center radius. This design provides greater mounting flexibility and will allow our users to clock the housing in whatever way they prefer. Check out some shots of our prototype bracket.

Prototype coolant filter housing bracket

Prototype coolant filter housing bracket

And a neat look at our drawing for this particular component!

Drawing of coolant filter housing bracket

Check back with us next time for a look at our filter, valve selection, and silicone hoses, as well as this kit fully installed!

Thanks for reading!