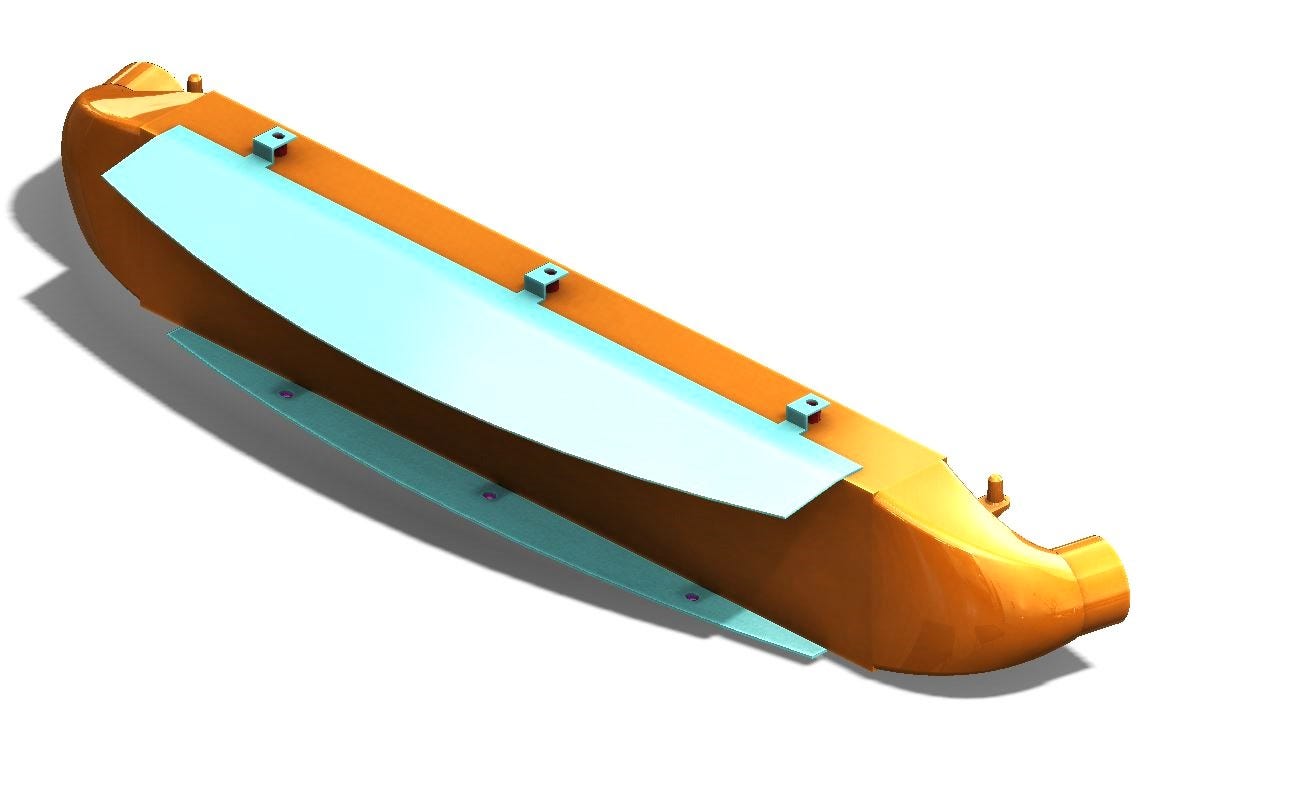

You may have seen our R&D post on the full Fiesta ST intake, but this one is a little different. We are developing a silicone induction hose as solution for drivers of mainly stock Fiestas who don't want to replace their entire intake system. The stock rubber hose can be restrictive due to its shape and size. We believe that by creating a more free-flowing alternative we could see some substantial benefits without heavy modification to the Fiesta.

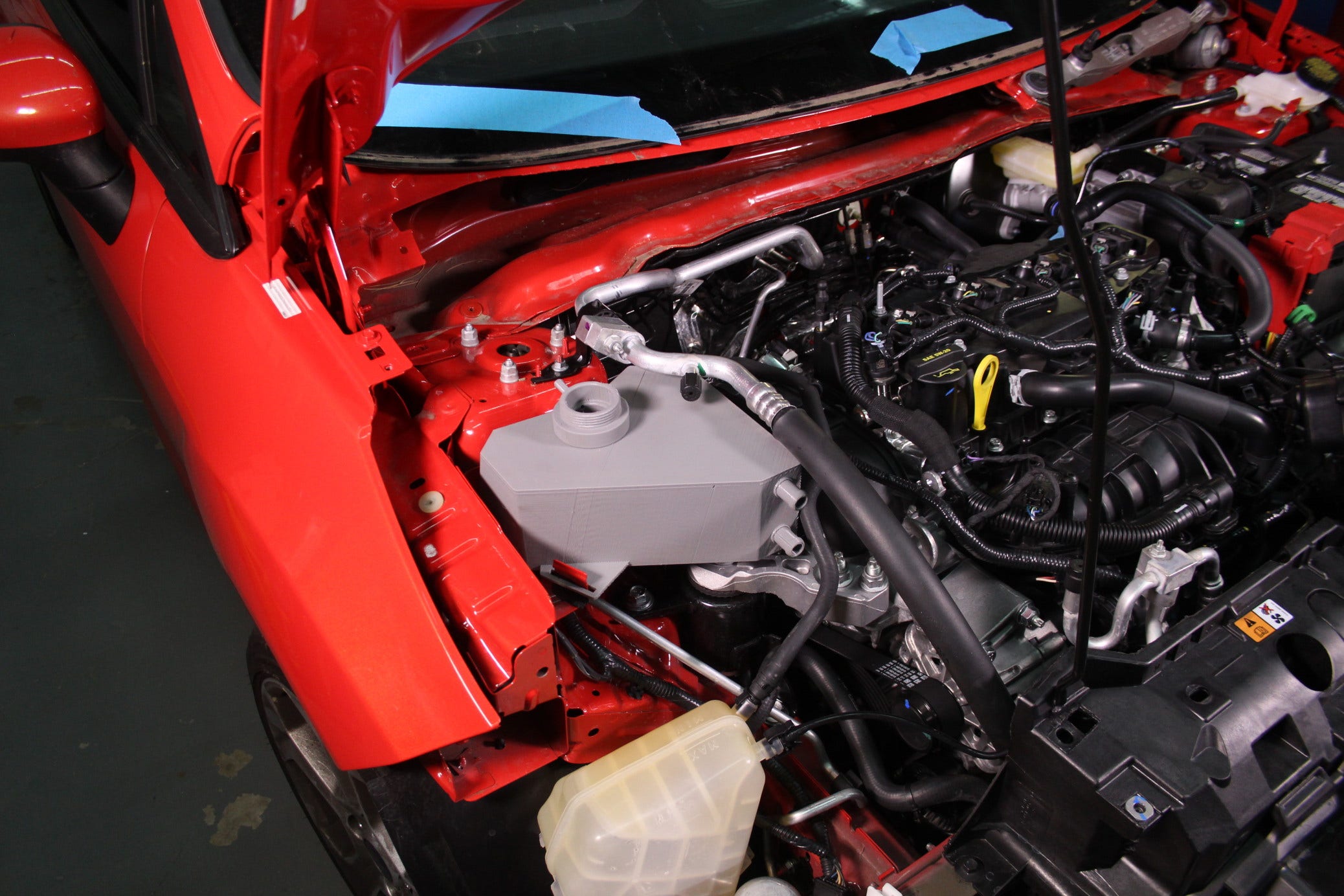

Stock Fiesta ST parts in the engine bay

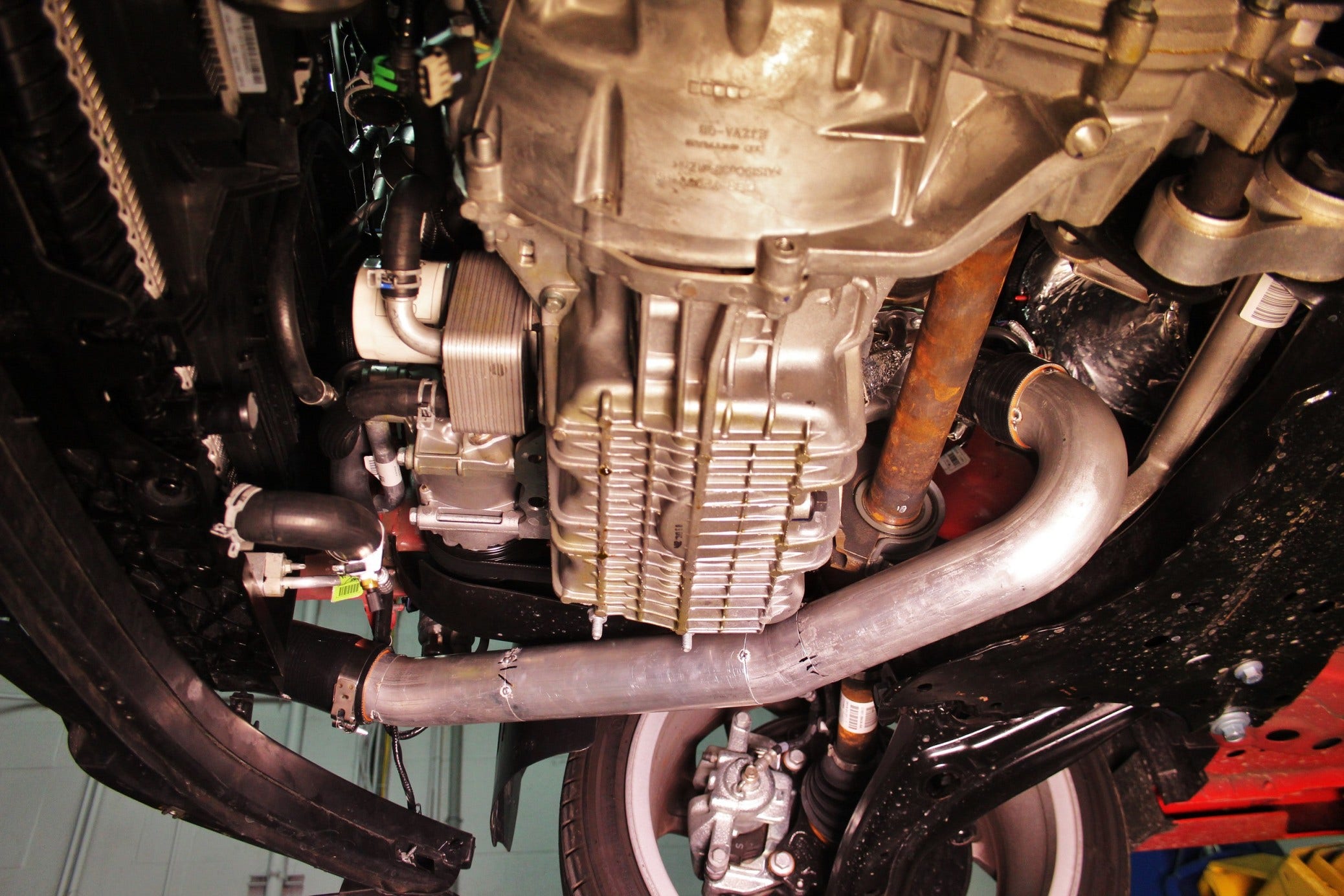

First we examined the features of the stock hose. Aside from a barb fitting, the hose has a fairly straightforward design. The stock hose has quite a few ridges and flex sections throughout, not to mention a small inner diameter.

" width="200" height="300">

" width="200" height="300">