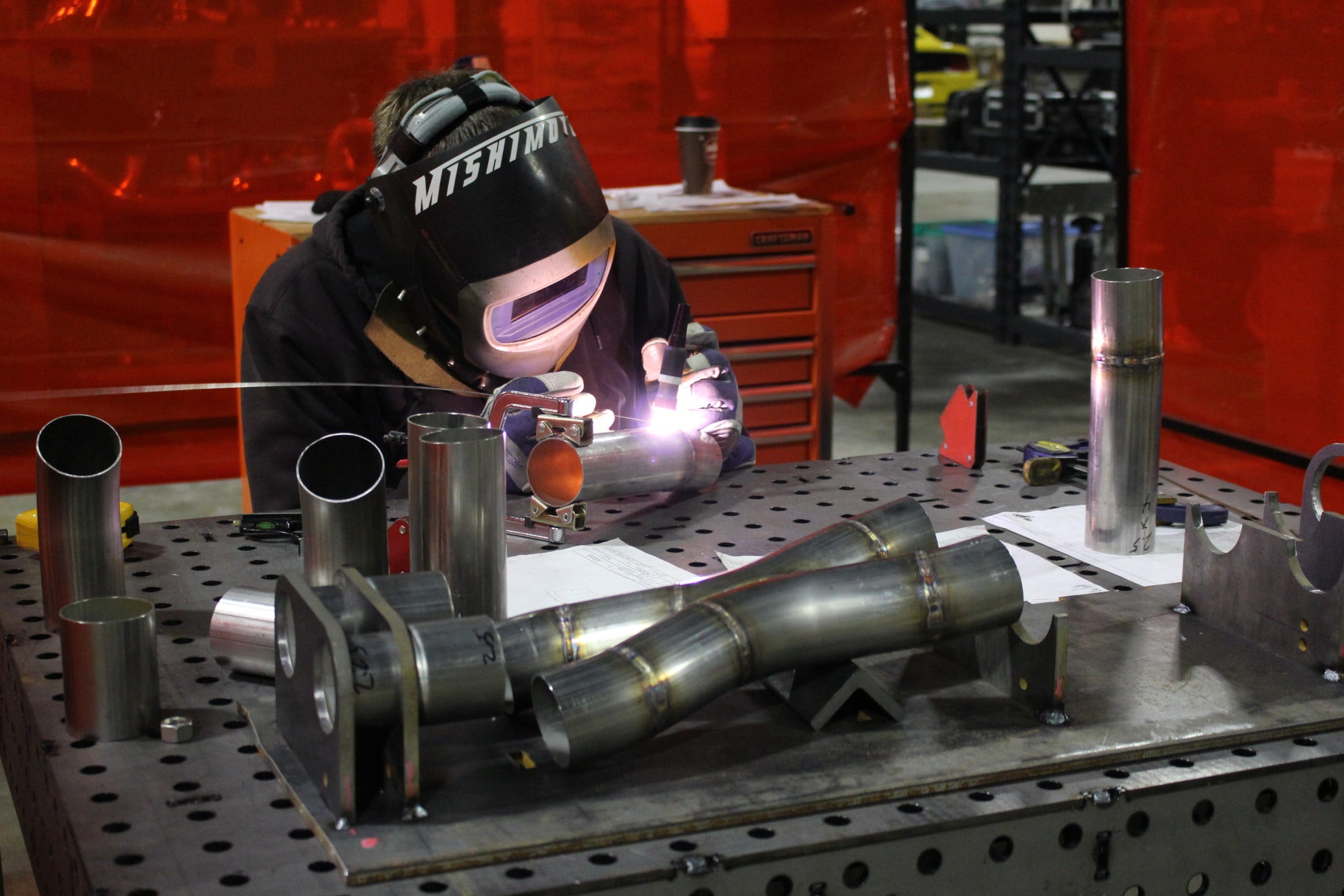

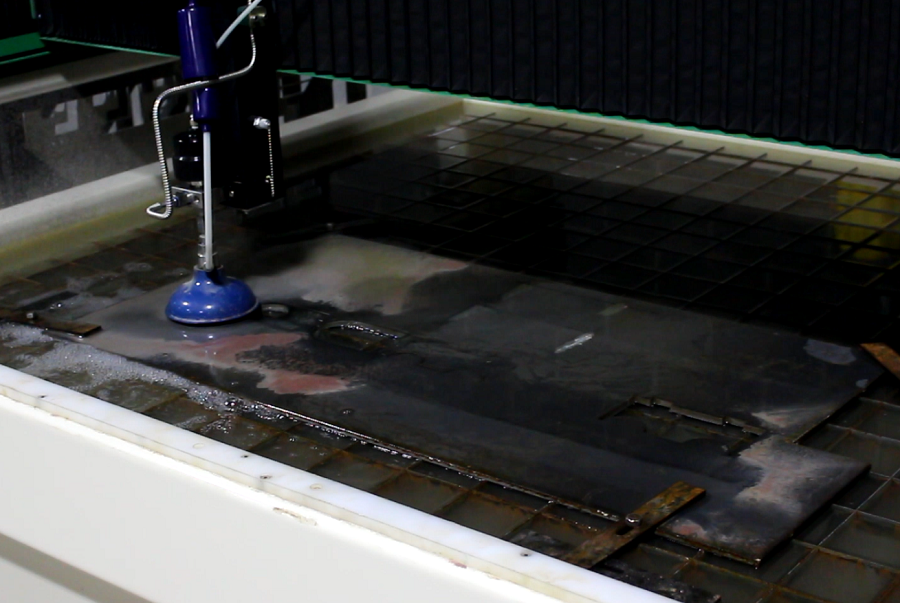

In our last post, we wrapped up the fabrication of our X- and H-pipes. Now that we have some excellent looking prototypes, it is time to put them to the test. We are not expecting much in the way of power with this modification; however we still want to give these resonator deletes the rundown for sound benefit.

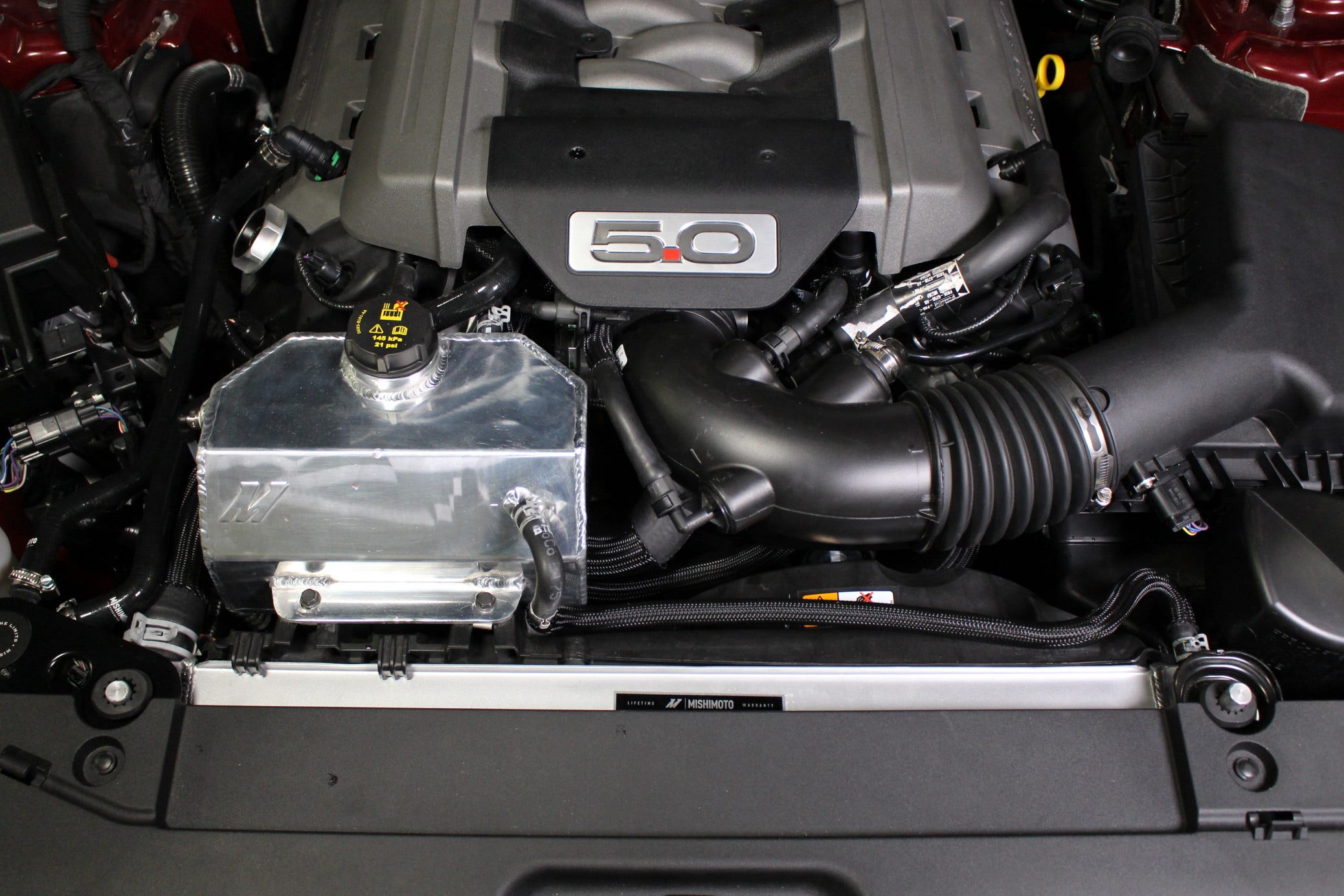

Mustang GT Exhaust testing

Testing

In addition to testing for any power increase we may see with our resonator delete, we will be testing our three different X-pipe designs to determine which one we will proceed with.

" width="900" height="603">

" width="900" height="603">

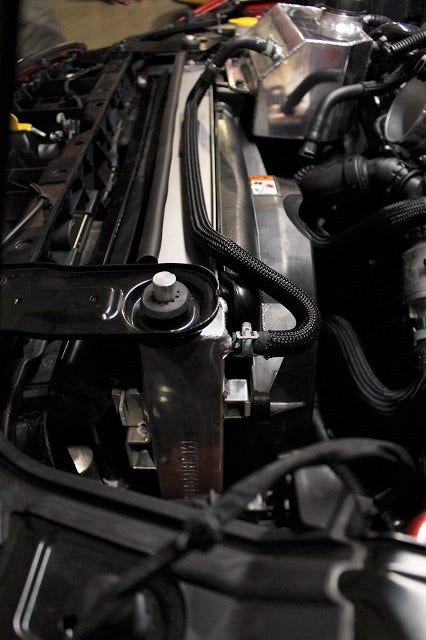

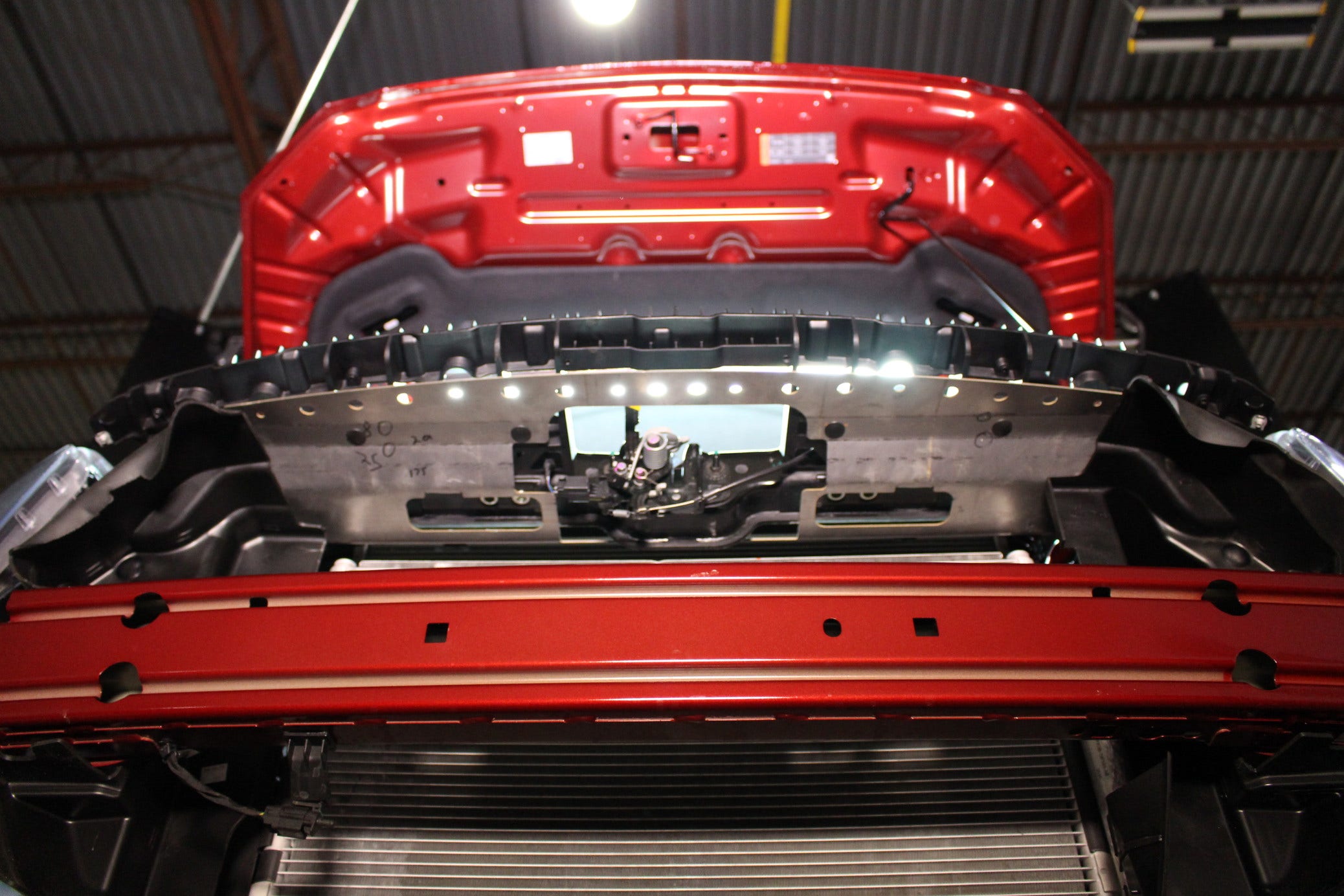

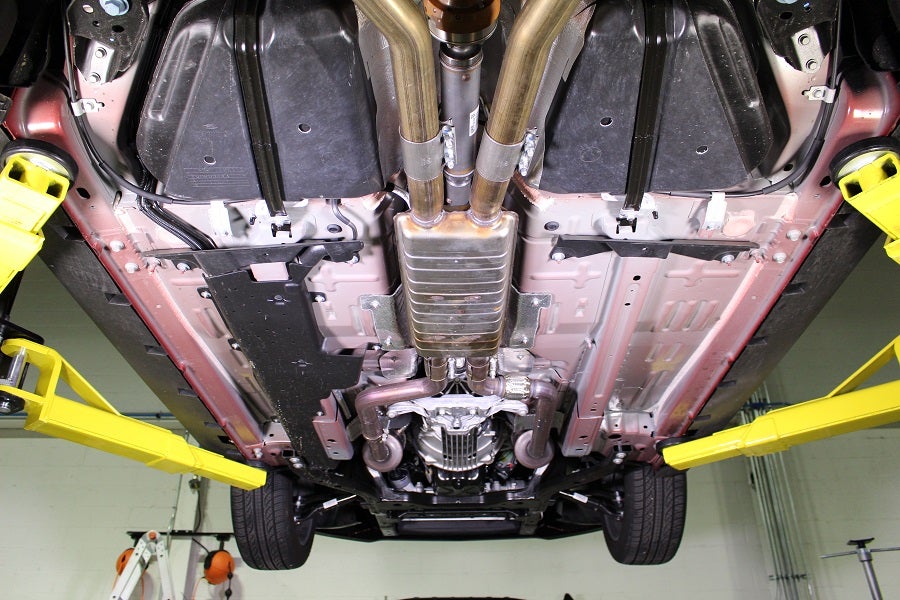

Stock Mustang GT exhaust

Stock Mustang GT exhaust Stock Mustang GT exhaust

Stock Mustang GT exhaust