Breathing Fresh Air - Intake R&D, Part 6: Dyno Testing

Product design, like most of life, doesn't always go as planned. We've learned to expect the unexpected and plan for unforeseen variables, but sometimes obstacles still catch us off guard. That's when we need to step back, take a deep breath, and find a way to navigate back on course. Our 2018+ JL 2.0T intake has hit one of those obstacles.

Our last post ended with few surprises. The 3D-printed prototype flowed 20% better than stock. That sizeable increase in flow was expected, given the simplified intake tube and large filter. The one small surprise was that there was no difference in flow between the prototype with the stock turbo muffler and the prototype with a straight-through adapter.

Like a high-flow exhaust resonator or muffler, the turbo muffler is a straight-through design with a perforated inner cylinder. The inner cylinder of the muffler is smaller than the outer cylinder and the perforations let some intake air fill the outer cylinder. The air in the outer cylinder then acts as a damper to change the resonant frequency of the intake, canceling out a specific frequency. So, while FCA calls this part a muffler, it's really more of a resonator.

Since we're designing for the enthusiast who loves turbo noises, we'll be running both prototypes on the dyno to see which sounds the best. We've already determined that the resonator doesn't hurt flow, so if it doesn't make a noticeable difference in sound, we'll leave it and save our customers some money. If the frequency that FCA spent hours of engineering time canceling out happens to be one of those lovely turbo noises, we'll go with a production unit that doesn't include the resonator.

Enough talking about the dyno. It's time to run our prototypes and see how they perform. Ye pulled the Wrangler onto our DynoJet four-wheel dyno and strapped it down tight. After rolling our dyno fan in front of the JL, she gave all the intake fittings and clamps one last check before firing up the 2.0T Hurricane. We let the engine get up to operating temperature and gave it a little throttle to check the straps, then began testing.

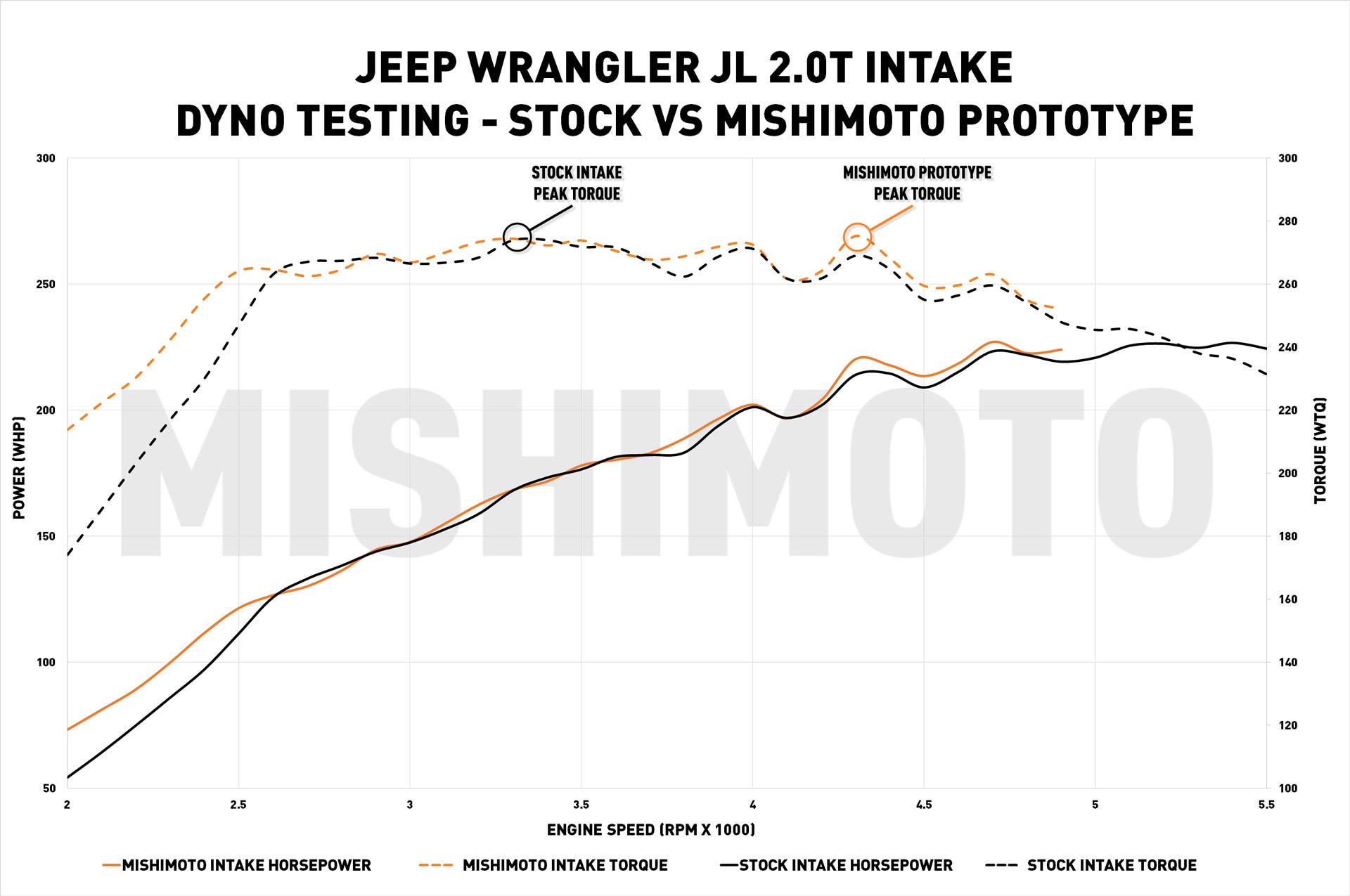

Our first runs were with the stock intake to get a baseline power figure. There were certainly no surprises here; the JL put down almost the same power it did last October in our first ever dyno run: 227 whp and 268 wtq. Our next runs would be with our two prototypes to determine if the turbo muffler made a difference in how the intake sounded. Ye let the JL cool down and swapped in the intake without any muffler. She ran the JL through the RPM range at wide-open throttle while we listened for a difference in sound outside and inside of the car. We then installed the prototype with the stock muffler and repeated the test.

The good news was that our prototypes let a little more noise out of the 2.0T Hurricane (check out the sound clip below). Surprisingly, however, there was no noticeable difference between the prototype with the muffler and without the muffler. The resonant frequency that the muffler canceled out must either be unnoticeable under WOT or a frequency we'd prefer to ignore anyway. So, that settled the muffler debate"our intake will use the stock muffler.

Looking at the power graphs revealed a less exciting trend. We weren't surprised to see that our intake made negligible power over the stock intake. Modern engines, and especially turbocharged engines, target a specified torque output at a given RPM. No matter how much more efficient you make the engine with intakes or exhausts, the computers will adjust fueling and boost parameters to make only that amount of torque. Without a tune, most modifications that improve engine efficiency don't produce power. While we weren't surprised by the lack of power gains, given our previous experience with modern turbocharged vehicles, we were surprised by how our intake affected peak power.

To compare our intake to stock, we focused on the torque side of the graph. Even though the two intakes made similar peak torque, the RPM at which that torque occurred was concerning. Where the stock intake makes peak torque around 3,250 RPM, our intake makes peak torque between 4,250 and 4,500 RPM. Even though the increased flow means low-end power comes on faster with our intake, we want peak torque to come on much sooner. Moving peak torque closer to the normal driving RPM range will greatly improve drivability. It would be pretty annoying if you had to go wide-open throttle every time you wanted peak torque out of your JL.

If you ask any old-school hot-rodder how important the intake manifold on a naturally aspirated V8 is, they'll tell you it's incredibly important. The intake manifold on a naturally aspirated engine can target power into certain RPM ranges by varying the design and length of the runners. As it turns out, the intake on a turbocharged engine can be tuned the same way, despite the turbocharger forcing air into the engine as fast as possible.

In the next post we'll show you where we went off course with our intake and how we plan to correct it. You might be surprised by which component of the stock intake we'll be bringing back. For now, though, take a breath of fresh air, relax, and keep an eye out for the next post.