As many of you are aware, we have explored nearly every inch of our GT in a quest to bring you some seriously awesome Mustang parts. While catch cans and oil coolers are exciting, we have a hunch that the most anticipated product is the Mustang radiator. Aluminum radiators are the staple component among our various product lines, so we were excited to show you our progress on this project.

The stock radiator is your run-of-the-mill OEM unit equipped with plastic end tanks. While there is nothing wrong with this setup for the average GT, we still see some room for improvement. First, Ford was on the right track when it equipped it's performance-pack version of the GT with a larger radiator. The performance-pack boasts a 36mm core, compared to the standard GT radiator that comes in at 25mm. We plan to offer our own version, which will have more capacity than either the standard or performance-pack options.

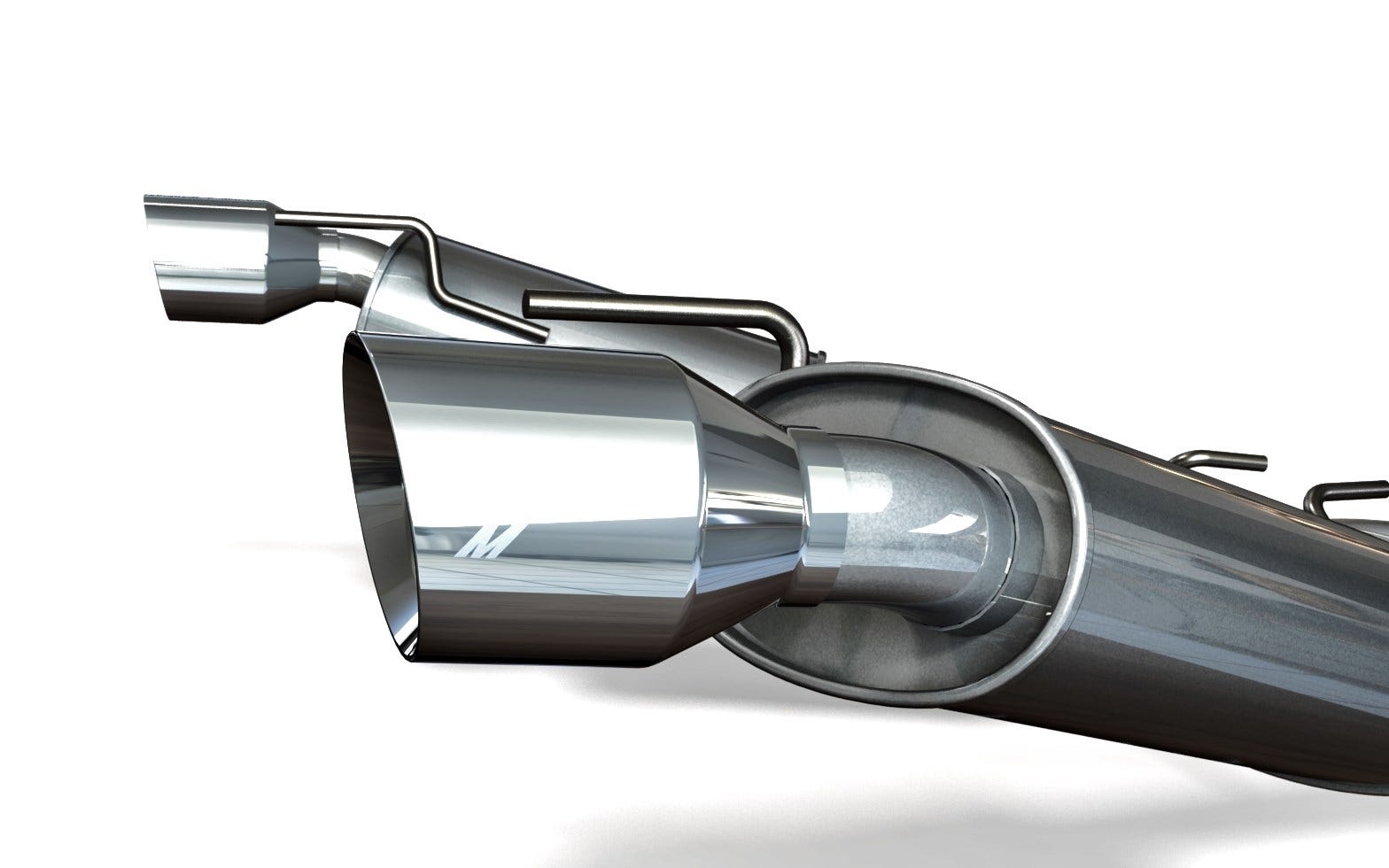

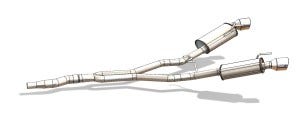

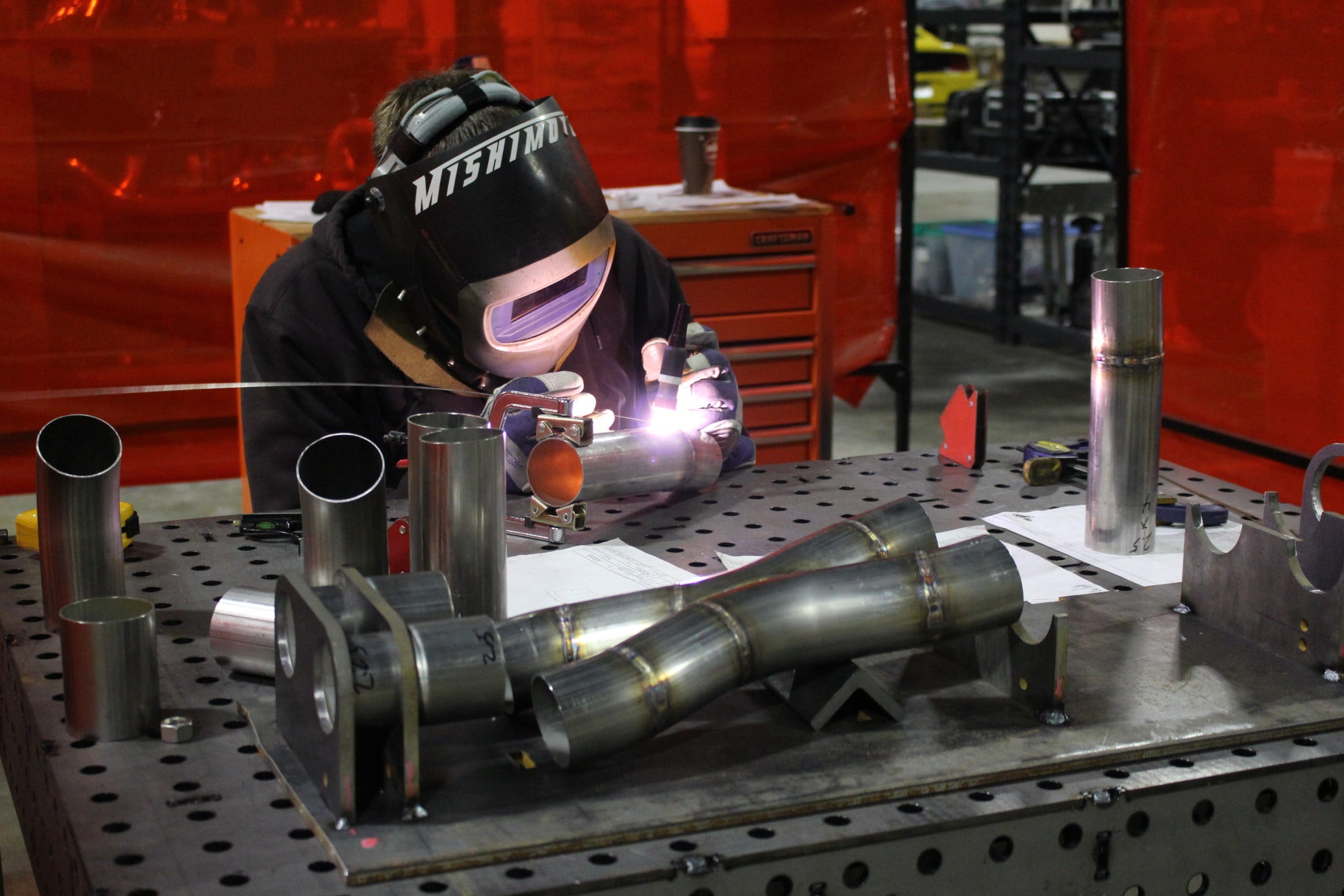

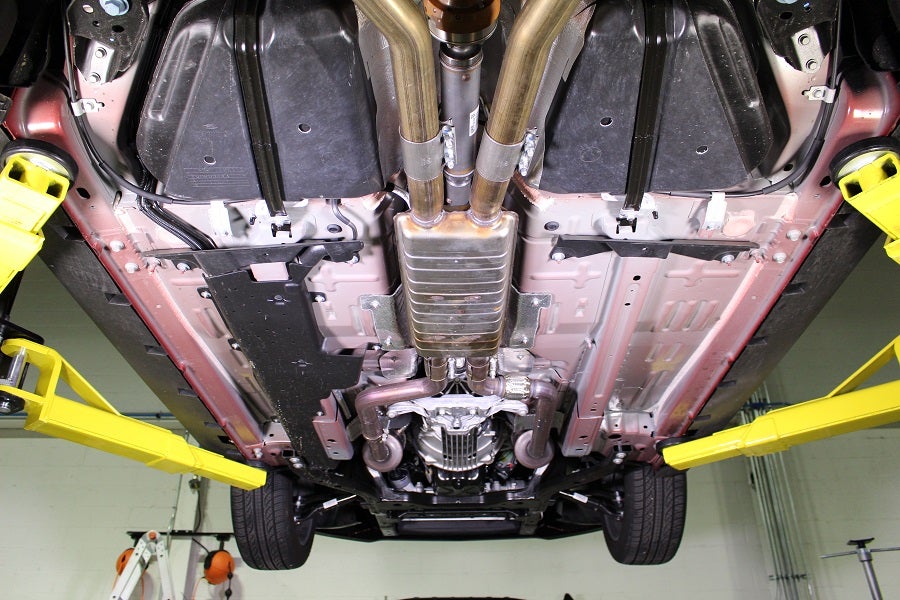

Stock Mustang GT exhaust

Stock Mustang GT exhaust Stock Mustang GT exhaust

Stock Mustang GT exhaust