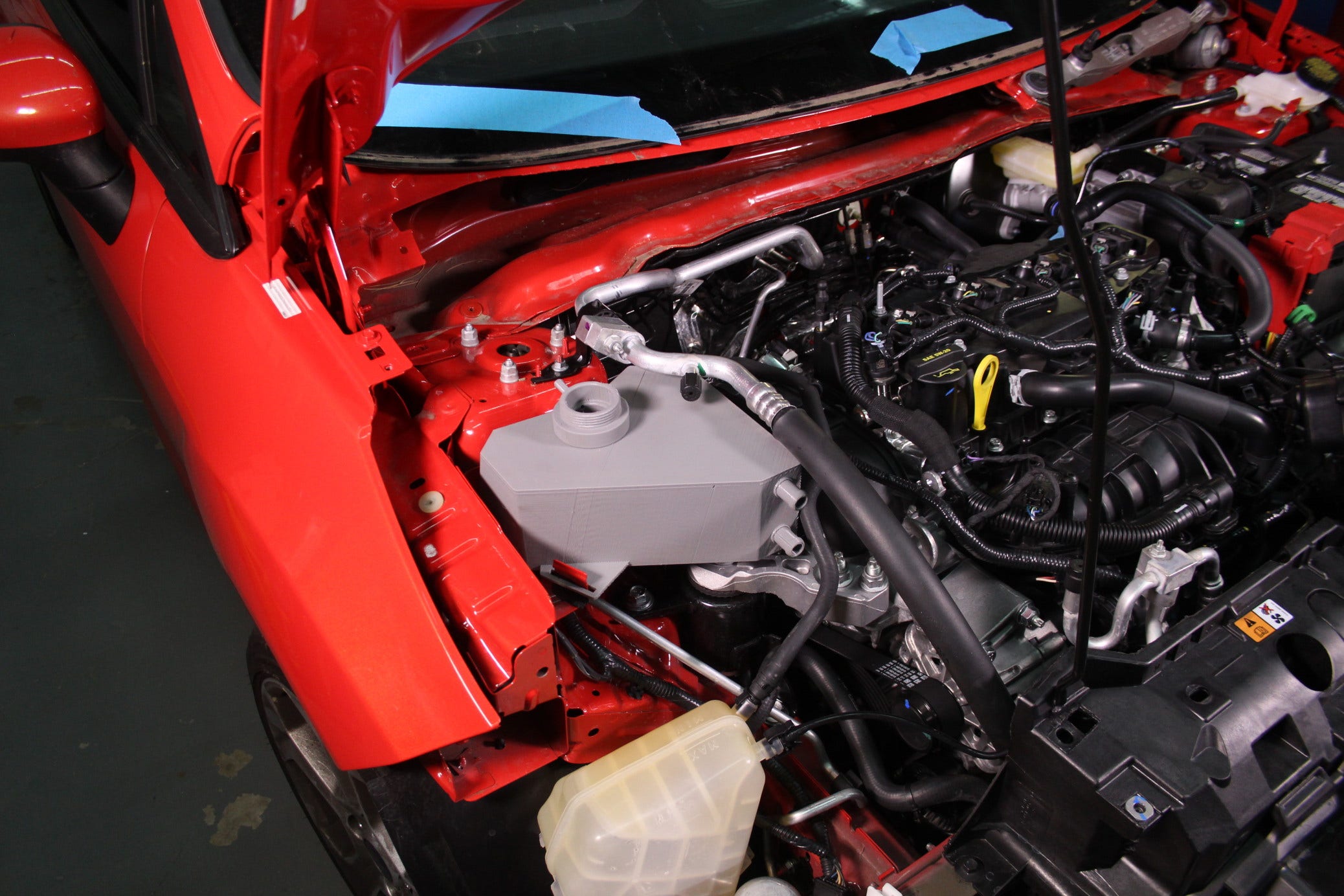

Time to dive into yet another Fiesta ST project! This little Fiesta is getting the royal treatment at Mishimoto; over the last few months it has been fitted for numerous upgrades. If you are in the mood for a recap, you can check out some of the other Fiesta posts here on the Mishimoto blog. For now we'll dive right into our development of Mishimoto's expansion tank for the Fiesta ST.

Stock Expansion Tank

Here at Mishimoto we feel a certain type of way about plastic. It is not that we have a vendetta against plastic, but we see an area where we can improve upon some of the stock Fiesta ST parts. Plastic expansion tanks in general (or any plastic parts) are more prone to failure than an aluminum part would be. Plastic becomes brittle with age, exposure to elements, and the repeated heat cycles in the engine bay. Replacing the plastic tank with an aluminum one not only looks better, but it also would be less prone to bursting or cracking especially as the