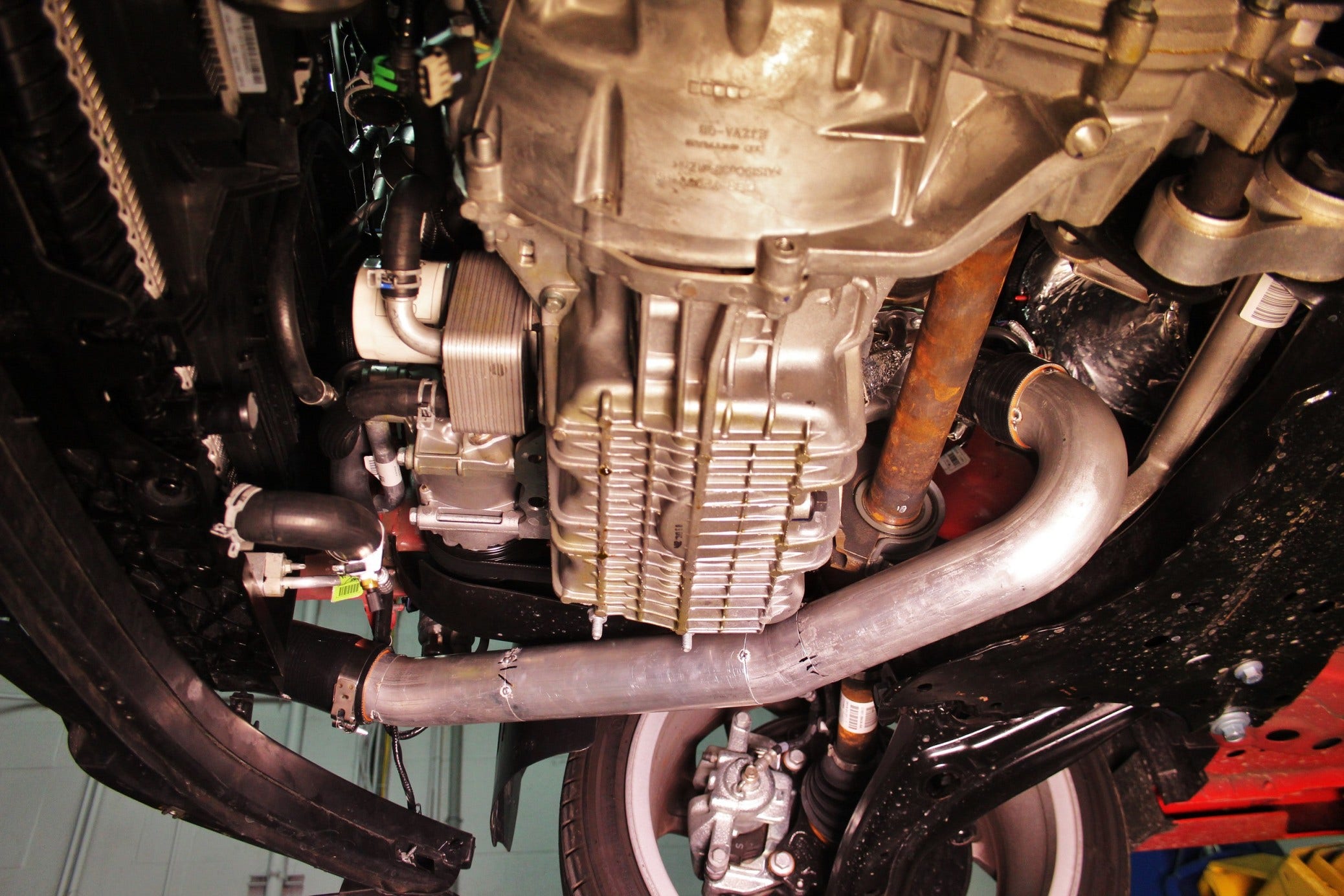

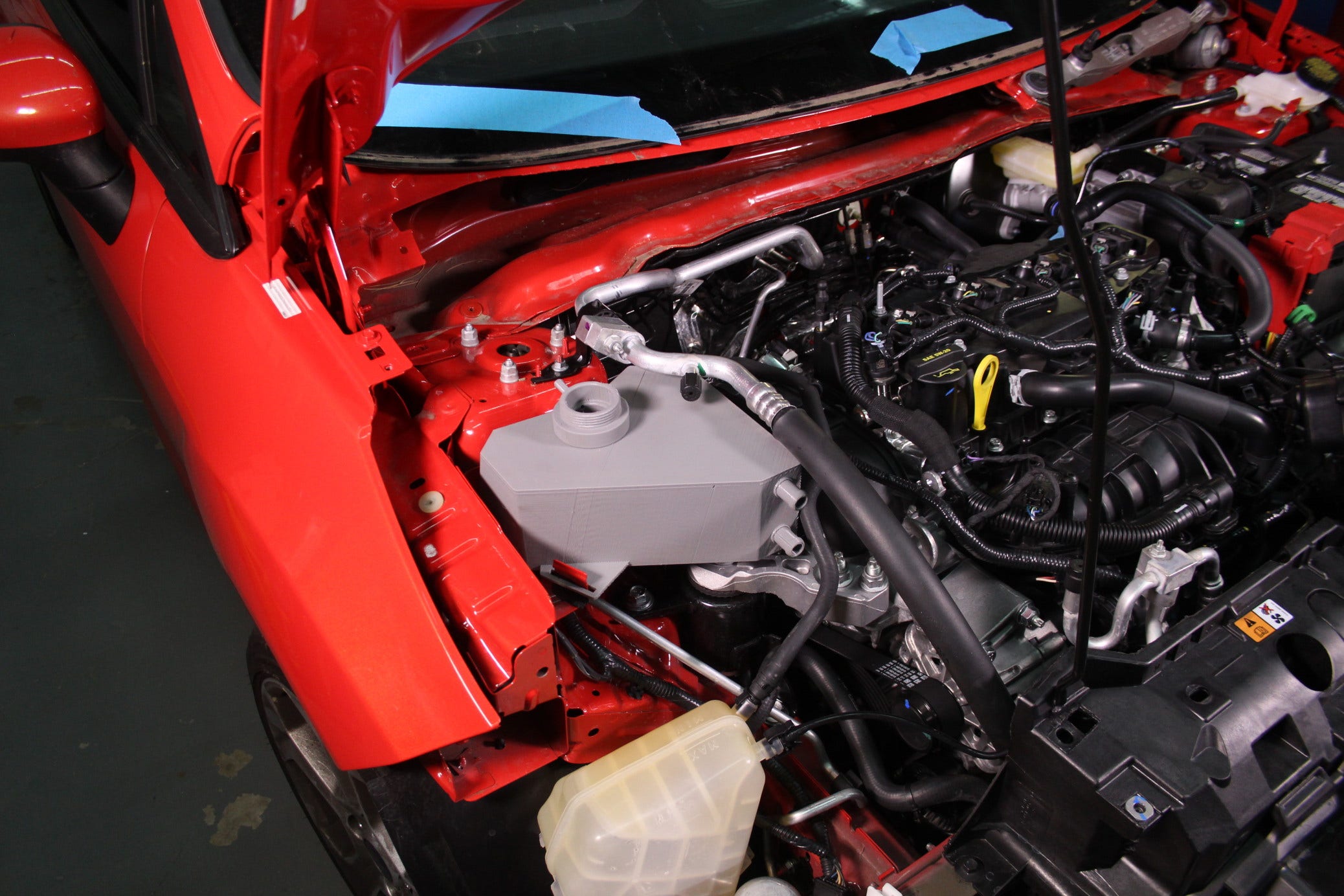

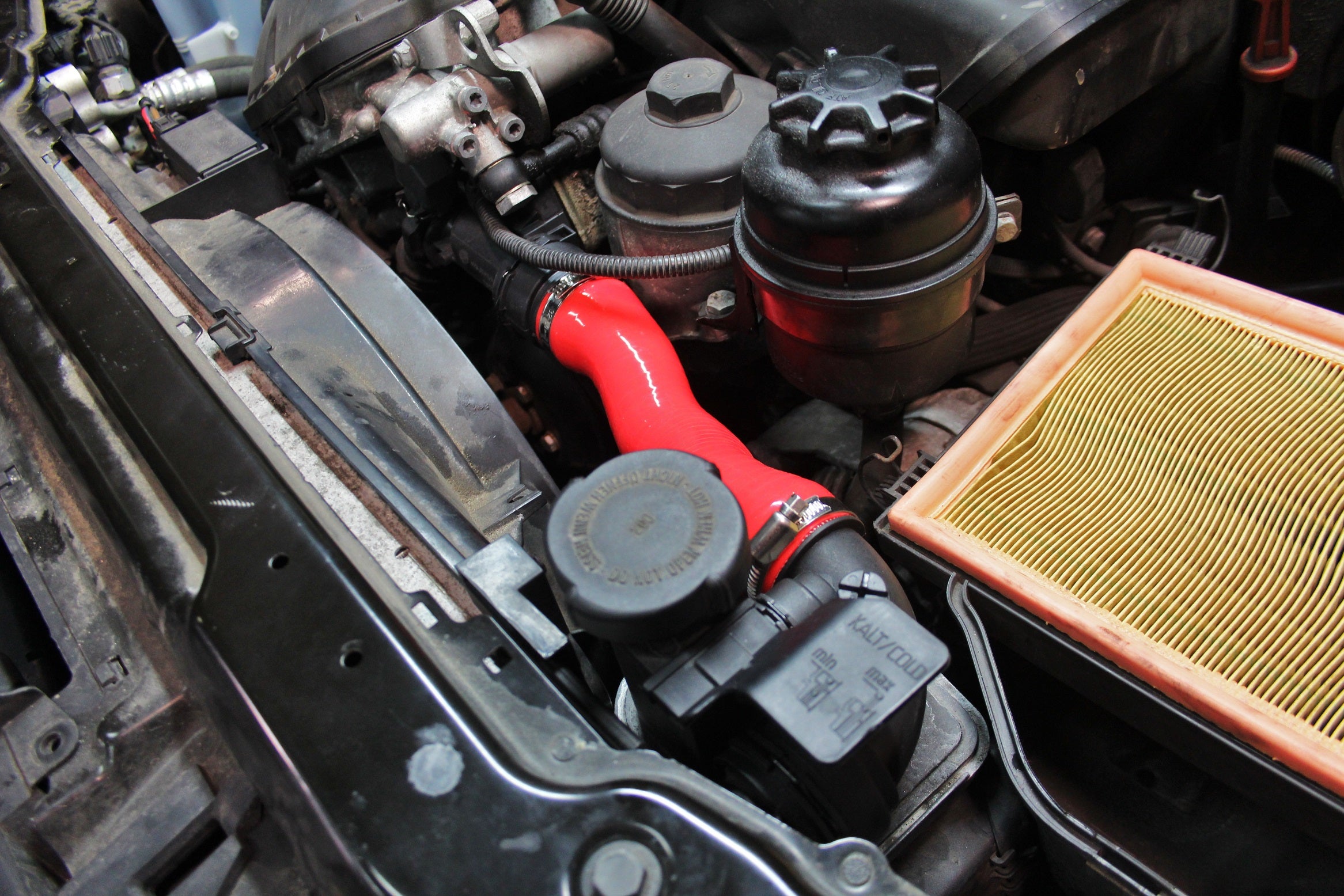

Our engineering team often tackles complex problems to provide ideal solutions for customers. This is true for all our product lines, across a broad range of vehicle makes and models. We are not strangers to Ford's lineup of EcoBoost models, and our team is quite familiar with the issues that exist for each. In general, we've found that the stock liquid cooling systems are not handling the abuse from heavy-footed ST (Fiesta, Focus) and Mustang owners. Each model shows deficiencies in coolant heat transfer, rising oil temperatures, and power-crippling heat-soak.

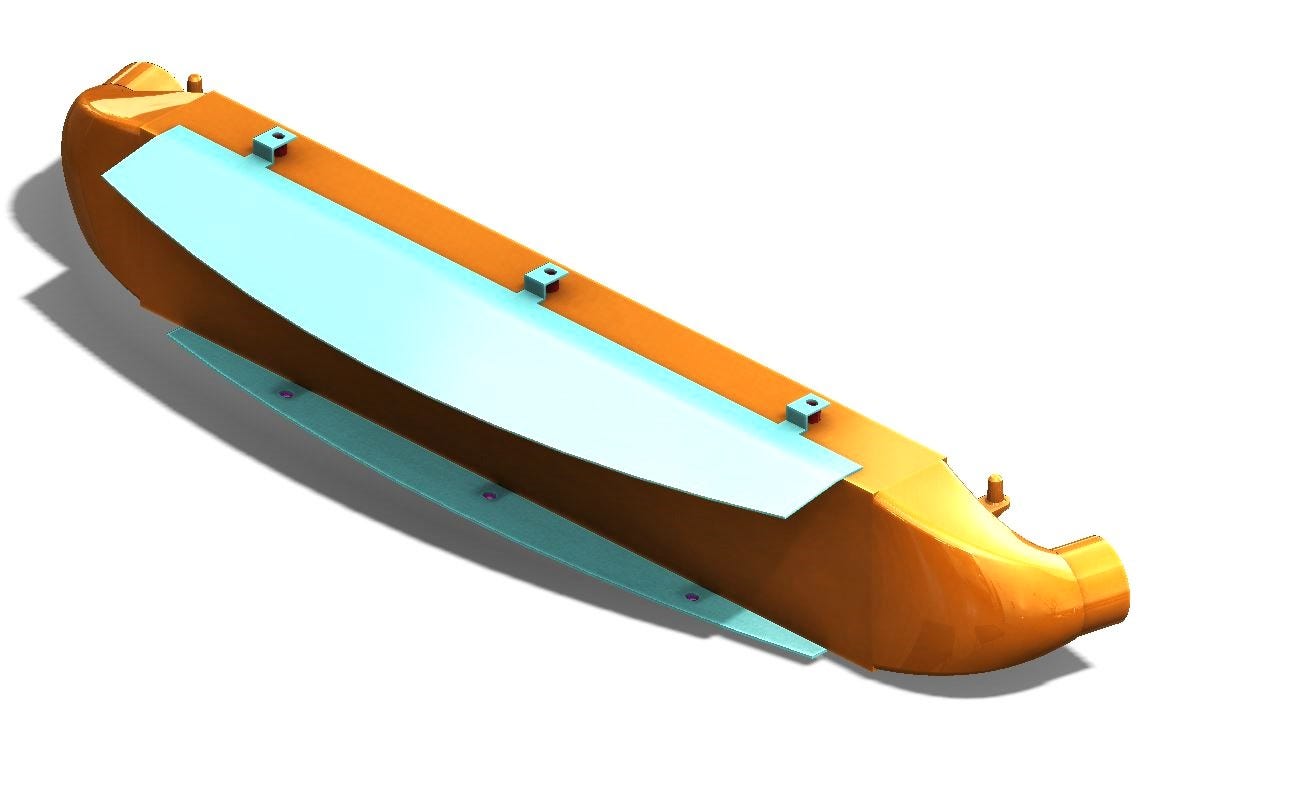

In our effort to solve each problem, we've started a ton of awesome projects, performed unique testing, and we've had a blast working with the EcoBoost community. Now, we turn our attention to the Focus ST radiator. This component has become the elephant in the room, if the room were the paddock at the track. All around the world, Focus owners are hitting the track expecting a fun day of battles against physics, rev-match downshifts,