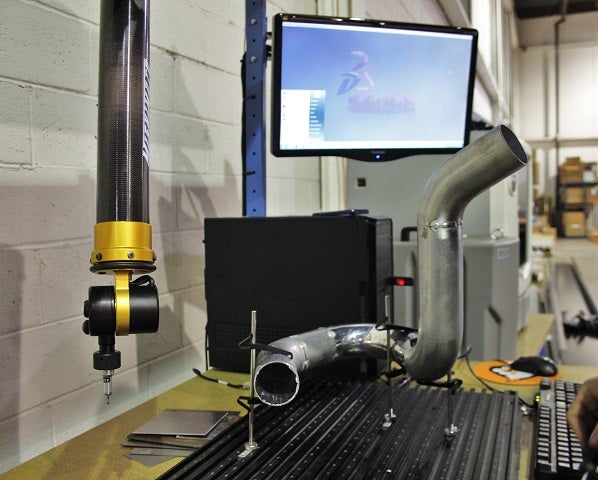

As we finally round the end of the long and arduous testing and data collection process, it's time to test the fitment of the final prototype to ensure there are no issues before we kick off full-scale production. A lot of effort has gone into designing and engineering this kit, and it has been rewarding to see this project finally come together.

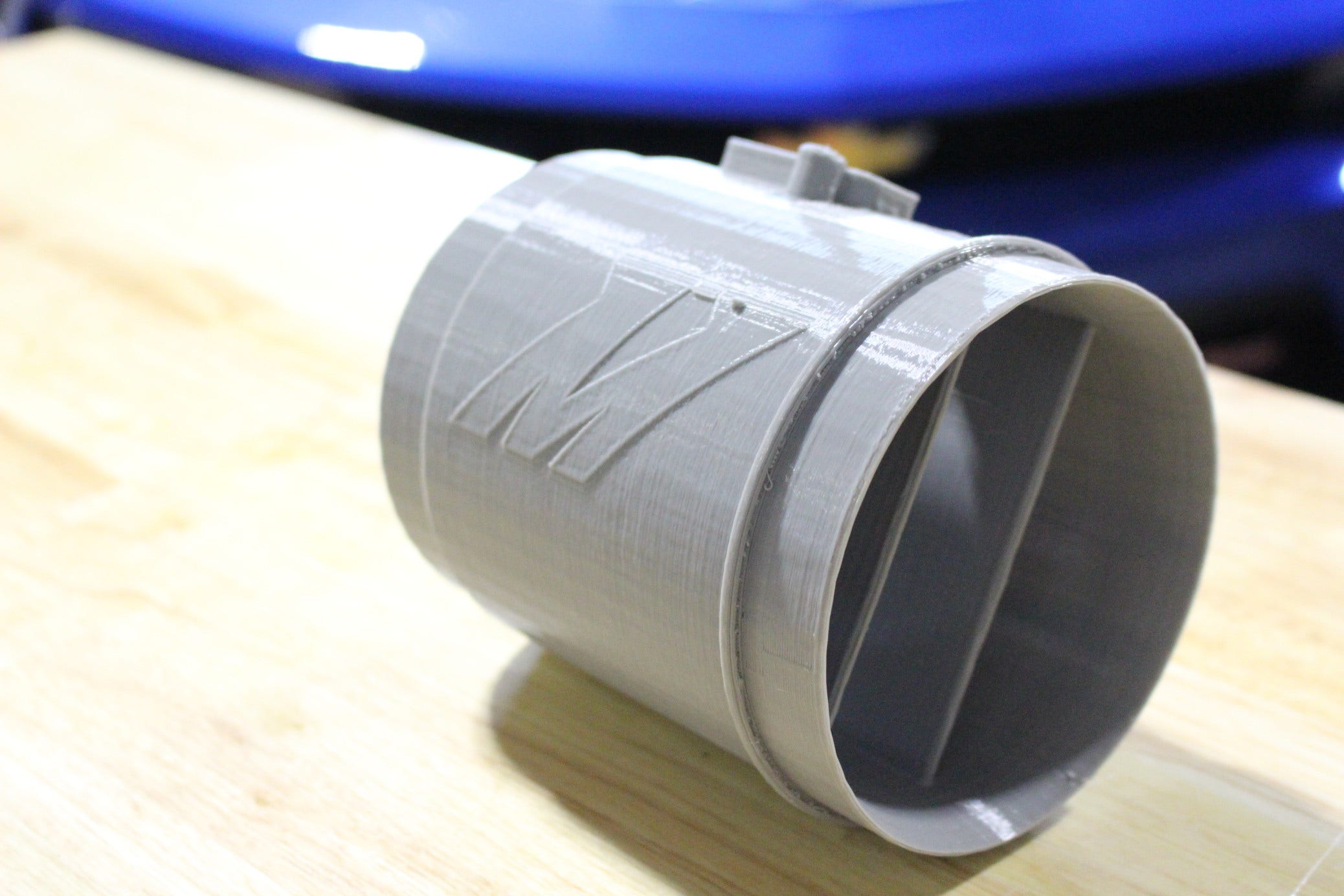

There were some minor changes and cool feature additions that will make this kit unique. Take a look at some images below.

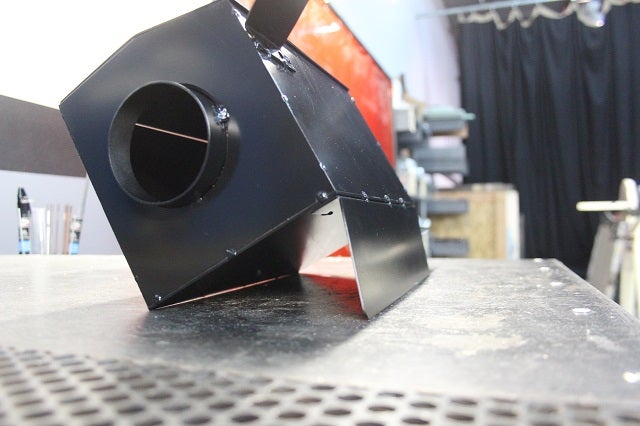

Prototype Miata intake box

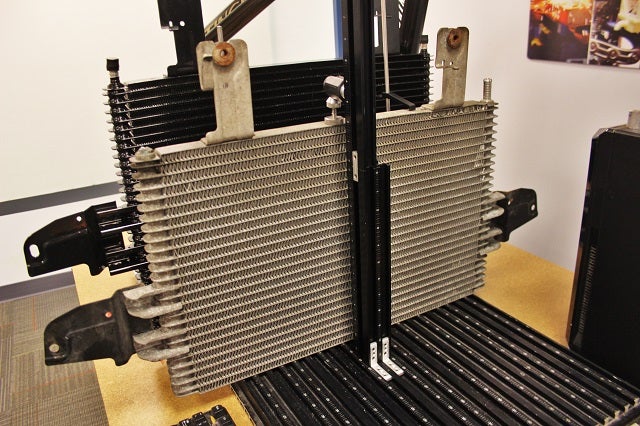

After we pieced together the rest of the box, we cleaned it up with some fresh paint and added a neat feature that will help with cooling. Right underneath the front of the box, you can see an angled plate that has been attached. This plate acts as