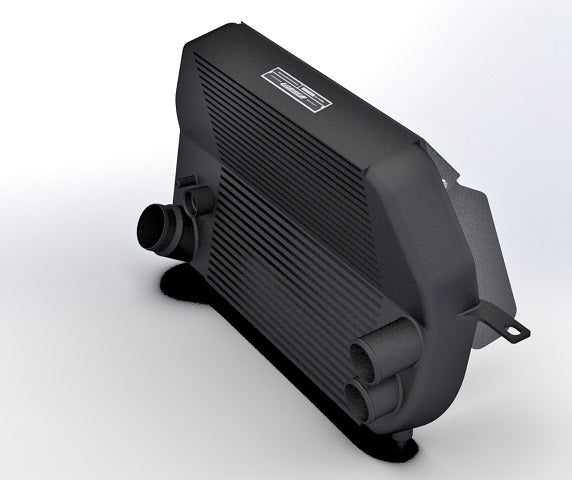

Along with creating an awesome intercooler for the EcoBoost (EB), we also want to improve upon the pathways through which air travels to and from the charge air cooler. This will involve replacing factory components that route from the turbocharger to the intercooler and from the intercooler to the throttle body with engineered aluminum pieces.

Factory Ford F-150 EcoBoost Intercooler Piping

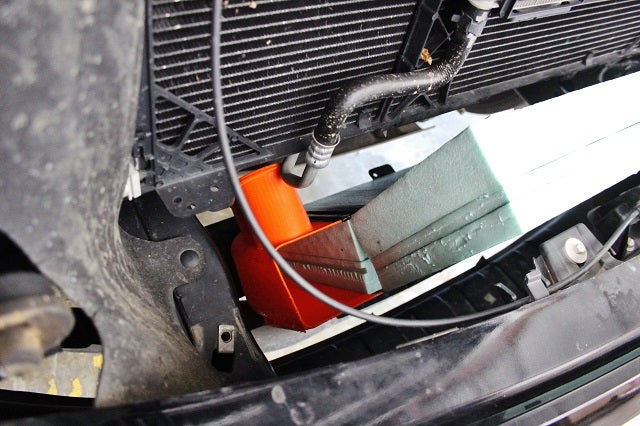

The factory piping setup on the F-150 is essentially a rat's nest of molded plastic and rubber couplers that, evident upon removal, is complemented by an internal coating of oil. No wonder catch cans are so popular for these trucks!

Our engineers felt like teenagers again with all of the oil on their skin as they removed the piping in order to inspect each piece, keeping in mind that they would need to replicate all connection points to ensure that our piping is a bolt-on setup.

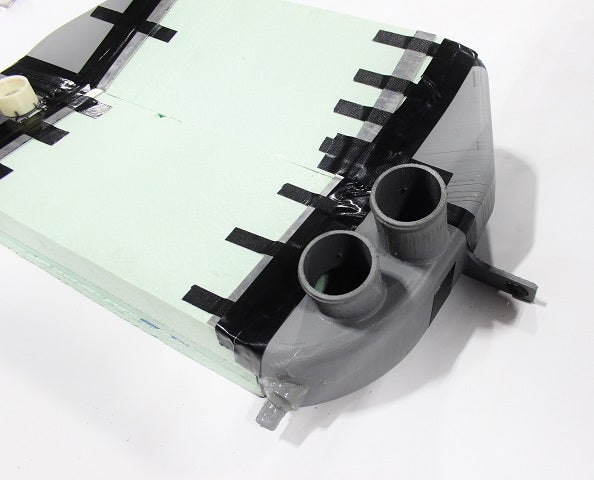

Check out the cold-side pipe, below.

" width="640" height="426">

" width="640" height="426">