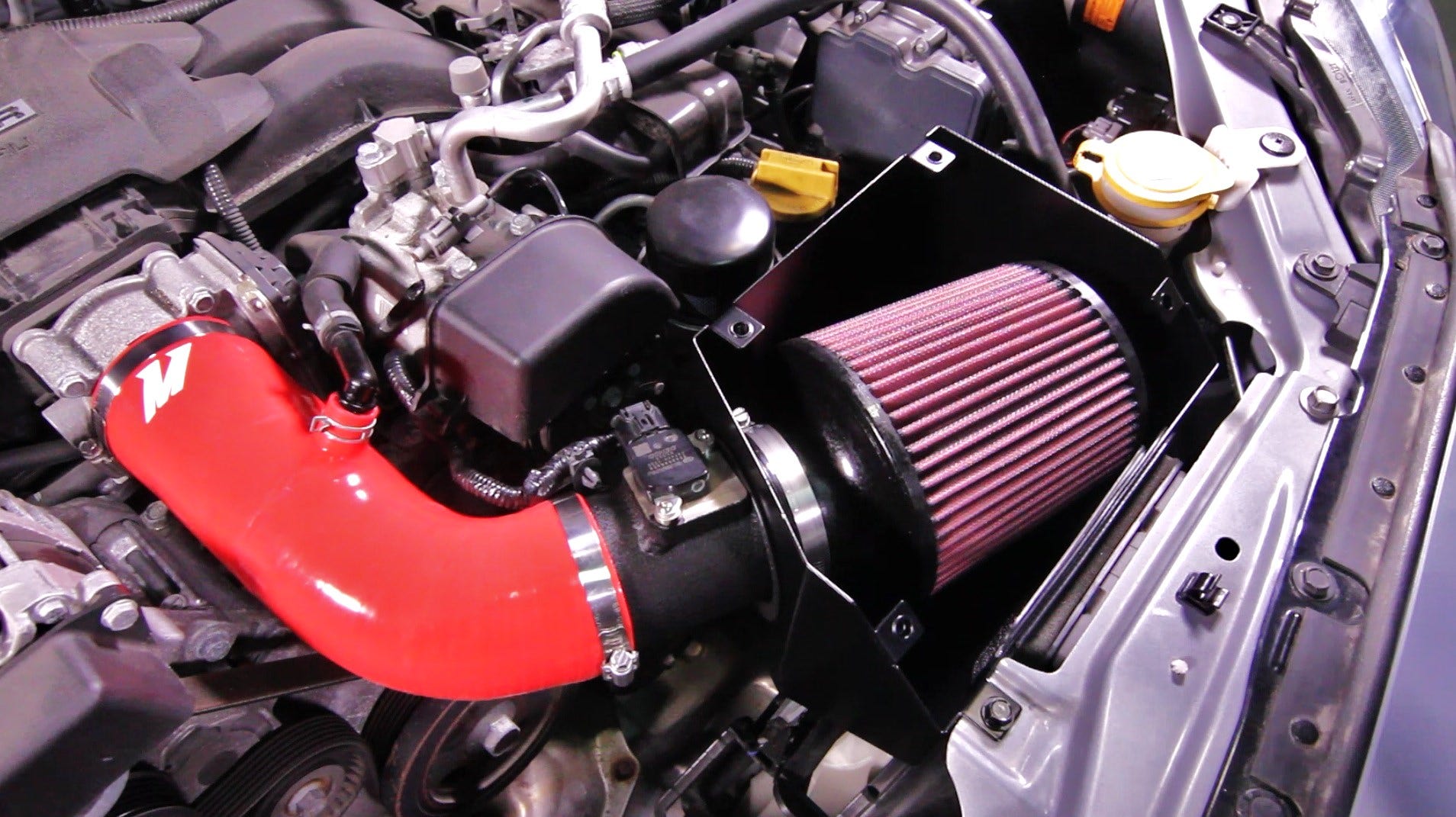

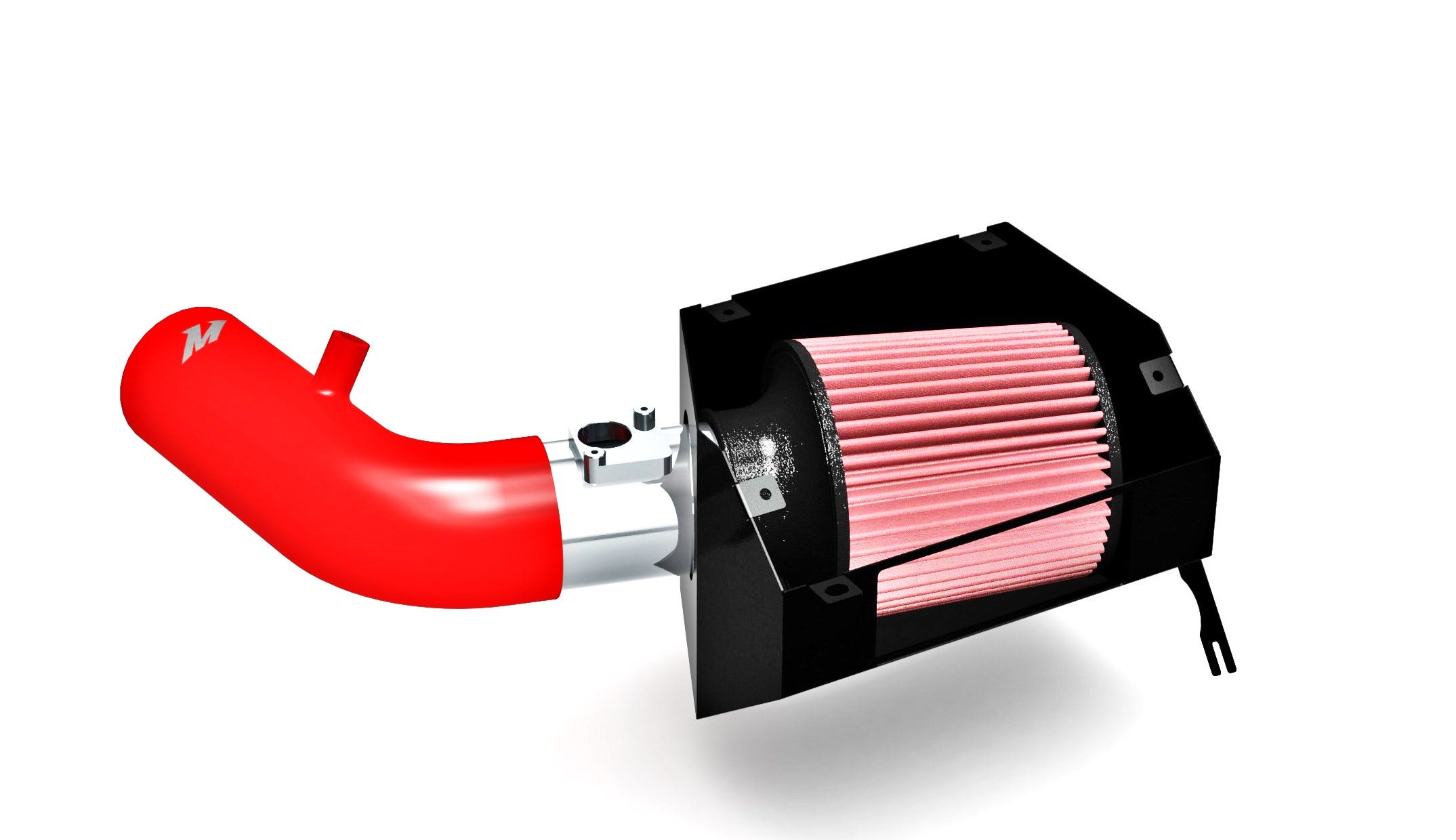

Interested in purchasing our new BRZ/FR-S intake system? Check out more details on our product page linked below!

Subaru BRZ / Scion FR-S Performance Air Intake

After solidifying our product design we needed to capture data to verify the design and determine if any changes were necessary. We strapped our test vehicle to the dyno and began making pulls! Check out a compilation video from the dyno testing. The audible difference in intake tone and volume is quite noticeable when comparing the stock setup with the Mishimoto prototype.

Testing Results

On to the important part, results from our tests. Intake upgrades generally