Rival Nature's Power - Intercooler Pipe R&D, Part 1: Stock Review

Nature is an awe-inspiring force. So much so that we often try to imitate its power. Any time we want to convey monumental strength, we turn to examples in nature. Animals, mountains, oceans, wind and the storms it builds, all have been the inspiration for man-made instruments of power.

The automotive industry is a perfect example of this. Automotive nomenclature, especially, has deep roots in nature. Who doesn't think of power when they hear "Dodge Viper"or "Ford Mustang" There are more subtle nods to nature's power too. The Volkswagen Scirocco, for example, is named after a Mediterranean wind that can reach hurricane speeds.

When it comes to naming engines, however, subtlety takes a back seat to sheer intimidation. Ford's Coyote V8 lives up to its vicious namesake with a lightweight aluminum block capable of producing 412 hp and 390 lb-ft of torque, but high-performance engines aren't the only ones to draw influence from nature. In the early 1950s, Willys Jeep and its various counterparts used the "Hurricane" codename for engines in some of their most renowned vehicles. Now, almost 70 years later, Jeep has revived the Hurricane name to create one of its most advanced and powerful Wrangler engines yet.

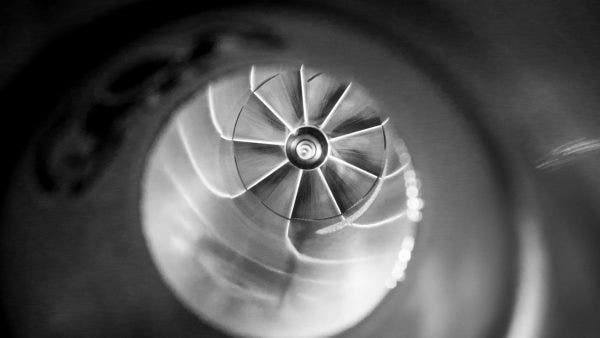

Like Ford's Coyote engine, the 2.0L inline four-cylinder Hurricane engine found in the 2018+ Jeep Wrangler lives up to its name. The Hurricane produces 270 hp and 295 lb-ft of torque with the help of a turbocharger acting as its own small hurricane. That power is enough to accelerate the JL Wrangler from 0-60 in 6.5 seconds, which is pretty good for a nearly 2 ¼ ton off-road vehicle. But, like almost every production engine, the Hurricane could be made better and at Mishimoto, we've been working to take the JL Hurricane from a Category 1 to a Category 5 and help your Jeep rival nature's power.

Modern turbocharged engines have massive potential for power. Improving airflow with intakes and exhausts and adjusting fueling through tuning can turn a mediocre turbocharged engine into a monster. We've already started improving the Hurricane's breathing with our intake R&D; now, we're moving along the intake tract to improve airflow after the turbocharger.

Connecting the Hurricane's turbocharger to the intake manifold (and the intercooler inside it) is the intercooler pipe. On many turbocharged vehicles, there are two sets of these pipes, a hot side and a cold side. The Hurricane, however, uses a compact and efficient air-to-water intercooler integrated into the intake manifold. While that means we have fewer parts to develop, that one pipe connecting the turbo to the intake manifold is significantly more complicated than a typical intercooler pipe.

Our goal for the JL Hurricane intercooler pipe will be to improve its flow characteristics to let the turbo breathe easier and shove more air into the engine. Before we can do that, we need to look at the stock pipe and establish which components need to be included in our upgraded pipe. On first inspection, it wasn't hard to see that there were three critical aspects of the stock pipe that we would have to account for.

On the manifold side of the intercooler pipe is a block with two sensors protruding through the pipe. These two sensors are the manifold air pressure (MAP) sensor and the intake air temperature (IAT) sensor. Combined with the engine speed sensor and exhaust oxygen sensors, these two sensors make up the majority of the JL's fueling calculations. The MAP sensor measures the amount of air going into the engine and the temperature sensor measures the density of that air. The combined readings of these sensors tell the ECU how much fuel to inject. To make sure these sensors are reading properly, we'll have to pay close attention to their position on the pipe and how far they protrude into the air stream.

Closer to the turbocharger is another critical component that protects it. In a turbocharged engine, exhaust spins the turbocharger turbine and the compressor forces air into the engine. If the engine is producing exhaust, the turbo is spinning and pushing air into the intake. This isn't a problem at idle because the turbocharger isn't moving more air than the cylinders are taking in. When this can become a problem, however, is when the engine goes from high RPM and boost pressure, to low RPM and less airflow, such as during a shift. When this happens, the turbo is still producing pressure, but that air has nowhere to go. If this pressure isn't released, the airflow and pressure in the turbocharger becomes erratic. This is commonly known as compressor surge and the stress it puts on the turbocharger can be enough to destroy it.

To prevent compressor surge, turbocharged engines utilize a valve to vent the excess pressure. That valve is known as a bypass valve. On the Hurricane, the bypass valve is an electronically controlled solenoid and is incorporated into the intercooler pipe close to the turbo. Like most OEM applications, the bypass valve on the Hurricane vents the excess air back into the intake. This type of valve is often referred to as a recirculating bypass valve. If you've been around turbocharged vehicles a lot, you may have heard this component referred to as a "blow-off valve." But the difference between the OEM recirculating valve and a blow-off valve is that a blow-off valve typically refers to a valve that vents the excess pressure to the atmosphere.

Blow-off valves are a popular modification on turbocharged vehicles because they make a lot of noise on shifts and are often able to handle higher boost pressures than the stock bypass valves. On many applications, however, the ECU sees the loss of metered air as a leak, which can trigger a check engine light and poor running. Many aftermarket manufacturers make upgraded bypass valves that still recirculate the air into the intake or can be adjusted to vent some air while recirculating the rest, so we'll try to account for these valves in our improved intercooler pipe.

Aside from sensors and valves, the stock intercooler pipe includes a few features to clear other components in the cramped JL engine bay and holdovers from the Hurricane's Italian cousins. A few of these features accommodate sensors in the Alfa vehicles, but they disrupt airflow in the JL. Since this isn't an Alfa, and we want the best flow possible, we'll smooth out the Alfa features. The dips and dents that clear other components on the engine will need to stay, but we'll do what we can to make sure they don't inhibit flow.

We certainly have our work cut out for us with the sensitive electronics and valves built into the Hurricane's intercooler pipe. But, we're well on our way to making the Hurricane live up to its name. In the next update, we'll measure the stock JL intercooler pipe and begin modeling our own. Keep an eye out for the next update and, as always, let us know what you think.

Thanks for reading,

-Steve