Next Generation Cooling - Transmission Cooler R&D, Part 4: Testing

This 1994-2002 Dodge Ram Cummins Transmission Cooler is now on sale! Click here to check it out!

Variables and constants - the two most important aspects of any scientific venture. For any test result to be accurate, a set of constants must be tested against one variable. The key in that equation being that there is only one variable. This concept becomes increasingly elusive as you begin adding more and more systems to the equation. Controlling our variables is a task we've become quite skilled in here at Mishimoto. After all, our everyday work involves testing extremely complex vehicle systems. But, we do sometimes meet challenges along the way.

When we last saw our 1994-2002 Dodge Ram Cummins transmission cooler, it was installed on our volunteer truck and patiently awaiting testing. However, we had some decisions to make before we could put the cooler through its paces. No matter how good we are at controlling variables in our testing, one variable we can't control is the weather. Summer temp testing is easy enough; the heat and humidity of Delaware's summers mean that we can consistently push stock coolers to their limits and have a good baseline to compare to. Winter testing is more complicated. Cold weather acts as a supplemental cooler and makes finding the limits of stock coolers difficult, while also amplifying the effectiveness of our coolers. When a vehicle is designed for high-loads, like the 2nd Gen Ram, cold weather makes testing even more of a challenge.

Of course, testing for this transmission cooler came in the late winter, when temperatures outside hover between freezing and miserably freezing. Given the cold weather, we had two choices: try to load our test vehicle enough to compensate for the cold weather during the road test or design a new testing method that eliminates the variable of weather.

Road testing was our first choice. Putting the vehicle under similar stresses as our customers' vehicles will give us as close to real world results as possible, most of the time. We knew we would need a heavy load to have any shot at finding the limits of the stock cooler in such cold weather. All our large trucks were under the knife for other projects, so our next best bet was our 2016 Camaro. As the 3,400 lb. car creeped onto the trailer, the rear suspension of the truck squatted under the weight. The creaks and groans of the trailer gave us hope that we could push the stock cooler to the edge of its abilities. Loading the truck wasn't our only challenge, however.

Traffic during road testing can also alter our data. Everything from how closely we follow the cars in front of us to how fast we drive makes a difference. Most of the time, we're able to perform temp testing on the highway, dyno, or, in the case of our Focus RS and Civic Type R, the race track. There we can mitigate or eliminate the variables of traffic. But, finding steep grades to push the stock 2nd Gen transmission cooler to its limits meant dealing with inconsistent traffic and speeds. To make a long story short, road testing wasn't working out. The data collection reflected inconsistencies, ushering us toward plan B.

Back in our test facility, we could control the variables. Ambient temperature, vehicle speed, and RPM were all under our control. The biggest challenge for testing this transmission cooler would be loading the transmission. Without a trailer behind our test vehicle, we would have to rely on the dyno for load. We have two dynos in our facility, our DynoJet roller dyno and our Dynapack hub dynos.

The DynoJet relies on weighted rollers to load the vehicle and calculate power. Those rollers are not enough to load the transmission on a vehicle made to tow several tons. The Dynapacks, however, can produce a huge amount of load to keep the hubs at a specific speed. That load would produce heat in the transmission, but it would also produce heat in the Dynapacks and risk overheating them. But, they were our next best bet for accurate data. So we bolted the Dynapacks to the truck and started testing.

Unfortunately, the Dynapacks still could not produce enough load to heat-soak the transmission cooler, and eventually overheated. Temporarily defeated, we returned to the drawing board. What we came up with would take all the variables, except the cooler itself, out of the equation.

After raiding the Betty Crocker™ catalog for a few tools, our engineers built a test apparatus that would directly compare the two coolers while controlling all other variables. Heat for the test would be provided by a turkey fryer filled with water and aided by a sous vide machine (basically just a submerged heating element that also circulates the liquid for a more even heat - great for steak, by the way). ATF and water have different cooling properties, so we couldn't just pump the hot water through our cooler and expect accurate results.

To get the heat from the water into the ATF, we submerged three of our universal transmission coolers into the hot water. The transmission coolers would work in the opposite direction than they normally do, imparting heat from the water into the ATF.

We plumbed in a pump and a reservoir to hold the same amount of ATF as the transmission in the truck, then connected it all to the truck's transmission cooler. The cooler was mounted on an open stand so that air could move through it freely. To produce that airflow, we created a shroud that would direct air from our massive dyno fan into the cooler. Our dyno fan is adjustable and allowed us to set the velocity of the airflow to a steady 10-12 mph. That may seem low for simulating road speed, but we've measured the air velocity after it passed through the grille of the Ram. At a vehicle speed of 60 mph, the air going through the cooler is moving at only about 10-12 mph.

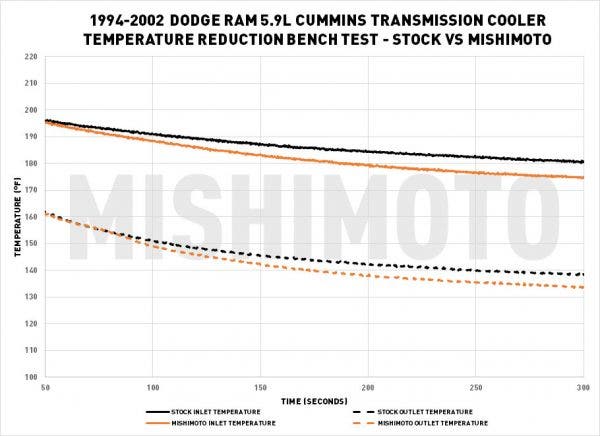

Ambient air temperature, air velocity, ATF flow-rate, and temperature were all controlled. The only variable in our test would be the coolers' ability to shed heat. So, we lit the burner, fired up the pump, and set the water temperature to a little over 200°F. Once the ATF at the cooler inlet reached 200°F, on went the fan and the temps dropped. What we were looking for was a steady state in which the cooler's outlet temp was no longer dropping. Once we reached steady state, we recorded the difference between the inlet temp and the outlet temp to tell us how well the cooler was working. This test was repeated for both the stock cooler and the Mishimoto cooler.

The Mishimoto cooler has a 116% greater core volume than the stock cooler, along with a 141% greater fluid capacity and 134% greater surface area. We were confident that it would outperform the stock version.

Our bench testing revealed that our cooler reduced the temperature of the ATF by about 5°F at both the inlet and the outlet when compared to the stock cooler, with a total drop across the core of about 41°F. Now, these are not road test results, but they do prove that our cooler is more efficient and more capable of cooling transmission fluid than the stock cooler. In fact, we believe that this cooler will perform even better on the road than it did in our bench testing.

This transmission cooler is currently on pre-sale. Be sure to check out our website for more information and to buy one for your truck. As always, feel free to ask any questions you may have and let us know what you think.

Thanks for reading,

-Steve