InterCOOLactic Planetary - 2017+ Honda Civic Type R Performance Intercooler Kit R&D, Part 5 - Piping Production Sample

It goes without saying that the intercooling system is an integral part of any turbocharged vehicle. What's the sense of trying to cram more air into the cylinders if it can't be compressed that easily. In fact, that almost defeats the entire point of having a turbo installed on your engine. For those of you who have a craving to crank up the heat on your hot-Honda by lowering your intake temps, we already devised a solution for you. However, much like how your CTR transports you from A to B, your chilled charged air still requires a delivery method.

Until we can somehow devise a pipe-less intercooler system, ensuring that we improve on the stock pipes is always a requirement.

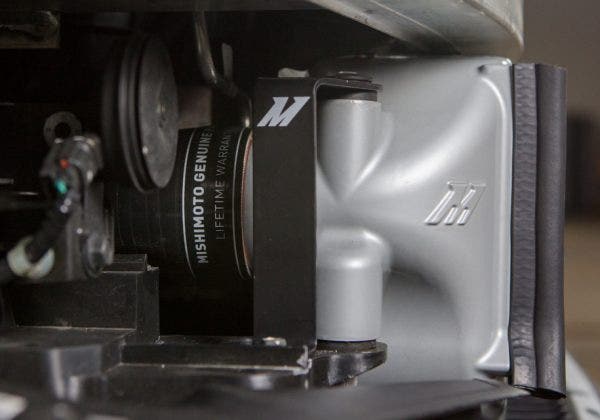

You might remember from our design plans post that we decided to ditch the plastic end tank construction and go with a full aluminum design better suited for the new, much more robust core. In doing so, we also changed the design on the inlet and outlet, rendering the stock piping all but useless.

Where the oval openings on the stock unit helped guide the flow through the entirety of the core, our new end tanks include a diverter that will serve the same purpose.

We did note in our review of the CTR's stock intercooling system that the piping was clearly devised to withstand the more demanding driving capabilities that the car was intended for. With that, the oval shape that Honda incorporated into the intercooler design was to aid in the flow of charged air through the intercooler, and make full use of the core, hence the funky looking adapters on the stock piping.

We could have easily designed our new end tanks with the stock piping in mind. However, Dan had his focus set on the future potential of the K20C1. The issue with the stock piping adapter is that their 58mm diameter will restrict the flow to and from your intercooler, and ultimately limit the performance, especially after installing a tune. Since making oval-shaped silicone couplers is a little tricky, and recreating the aluminum adapters would be pricy, we went back to the classic circle shape all while improving on the performance.

Silicone is the material of choice when it comes to replacing Honda's intercooler piping adapters.

Don't worry, it's meant to look like that. Given the tight squeeze around the front cooling stack, Dan had to add some extra curves into the couplers in order to fit and retain a larger diameter.

Much like how creating a new intercooler is a balancing act, it's also crucial that we get the piping diameter just right. Where the stock piping would eventually become a restriction, opening the piping diameter too much would cause a massive drop in boost pressure, which is just as bad as creating a choke point. Our engineer found that a 2.5" mandrel-bent section of pipe was the best option for optimizing airflow on the cold side, and adding an extra splash of color to your CTR's engine bay.

Not only will you be improving the flow of your intercooling system by installing our pipes, but also sprucing up the engine bay with the Rallye Red cold-side pipe option. For those of you looking for a less conspicuous aesthetic, they will also be offered in wrinkle black.

Where our cold-side pipe is coupled with specifically designed silicone pieces, our hot side is a single section of the stuff. Using 5 layers of durable silicone embedded with heat-resistant fibers, this new hose reduces the risk of leak points and is more than tough enough for the turbo K20.

With the charged air delivery method sorted out, our hefty new intercooler makes much more sense. On paper, and installed on the car, our new design looks great, but the true test of our new intercooler kit comes after CTR #1254 spends some time on our Dynapacks.

Thanks for Reading!

-Nick