Dependably Cool - Radiator R&D, Part 1: Design & Test

This 1999-2014 Silverado 1500 V8 Performance Radiator is now available! Click here to check it out!

The early 2000s presented two polar opposites of the auto industry in America. Small, fuel-efficient cars were still growing in popularity following yet another oil scare nine years earlier. Imports looked like the future of transportation. But for many hardworking Americans, nothing could replace their trucks. In 1999 Chevrolet introduced the Silverado and the GMT800 platform. Encompassing 11 truck models, the GMT800 platform quickly became one of the most popular in the country. By 2000, Silverado sales had surpassed those small imports and the truck landed as the second best-selling vehicle in the country.

Back then, Chevy's slogan was "Like a rock." That phrase exemplified the dependability of their trucks and the people who drive them. And, for 15 years the Silverado has stood up to that reputation. In 2014 Chevy switched over to the K2 platform for their trucks, but even four years later, GMT800 (and the later GMT900) Silverados still see thousands of miles of work every year. But like a rock, nature and time have taken their toll.

While the Silverado was offered with a Duramax diesel engine designed for heavy-duty use, most Americans opted for the versatile Vortec V8. The Vortec V8 is a great all-around engine that is capable of reliably handling everyday errands and just about anything the weekend can throw at it. These trucks can be found on job sites, towing race cars, and ferrying children to soccer games. Unfortunately, some can also be found on the side of the road with their hood open and steam pouring out.

Eventually every part of a vehicle will need to be replaced, but few parts have a harder life than the radiator. Constantly filled with hot, corrosive coolant and smacked by debris traveling at highway speeds, the radiator takes a beating. The average 1998 Silverado has seen about 200,000 miles of driving, and its radiator has been keeping it cool for every mile. That's like asking you to work 24 hours a day for over 130 days without a break. And you don't spend your work days swimming in 210*F coolant. I hope.

The radiators of many GMT800 and GMT900 trucks have either bit the dust or are well on their way thanks to that arduous life. But with the precise application of engineering and aluminum, we can keep these trucks cool for another 200,000 miles.

Our goal is simple. We don't want to create a giant cooler for the drag strip that takes hours to fit. We don't want to create a plastic end-tank radiator that would fail again in 10,000 miles. We want to create an all-aluminum radiator that installs easily in the stock location and stands up to anything daily errands and weekend road trips can throw at it, just like the Vortec V8 that it cools.

Designing the Silverado radiator was a relatively simple task. Like many factory radiators, the plastic end tanks were designed to fit the radiator support and the core was designed to fit a budget. The core of the stock radiator does not take up the full width of the end tanks. A thinner core equals less money, but it also equals less cooling.

Some radiator cores are thinner than the end tanks to fit fan shrouds and other mounts. But the fan shroud on the Silverado mounts on the radiator support and the radiator tucks under that support. That gave our engineer plenty of room to make the radiator core thicker, and a thicker core equals more cooling. Of course, a larger radiator that doesn't fit is useless. Using information from Chevy, and measurements taken on a loaner Silverado, we made sure that our radiator would fit just as easily as the stock unit.

Great design means little if it doesn't work well in the real world. Shortly after our radiator was designed, our production sample was ready to begin testing. But first, we needed a truck to test with. We often spend days or months looking for suitable test vehicles. However, this radiator fits a massive range of trucks, and one of our project managers drives one every day. Our plan would be to test fit the radiator on his 2000 Tahoe, hitch our enclosed trailer to it, and hit the steepest grades we could find.

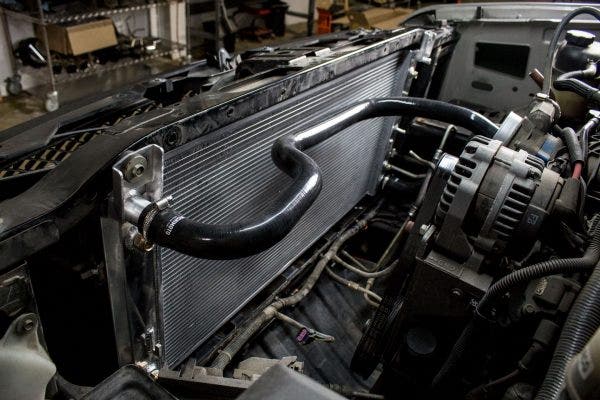

Our engineer's careful measurements and the ample room in the truck ensured the test fit went smoothly. Even with a 92% thicker core, the radiator slid under the radiator support without a hitch. We cinched down the clamps on our silicone radiator hoses, filled the coolant, and reassembled the Tahoe for road testing.

A few days later, mother nature gave us the perfect day for testing. We pulled the Tahoe out of our facility as the temperature rose to 79*F and the sun beat down on the asphalt. Our 4,500 lb. enclosed trailer would serve as the test weight. The project engineer finished hitching the trailer to the Tahoe and hit the road.

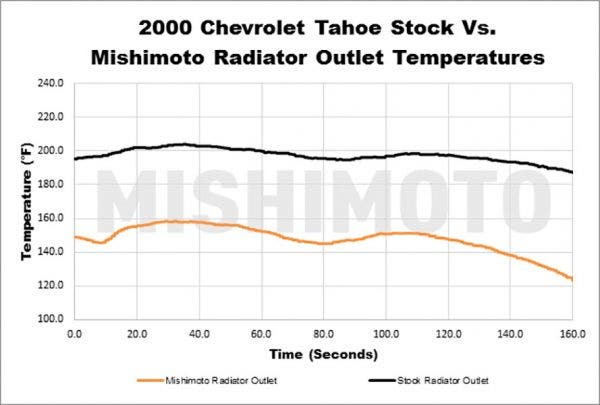

Testing would take place in the hills of eastern Maryland, just 30 minutes west of our engineering facility. As the truck and trailer crested the first hill, we hit start on our data logging equipment. Two temperature probes relayed radiator inlet and outlet temperatures to the laptop sitting in the passenger seat. Another system logged transmission fluid temperatures reported by the OBD system.

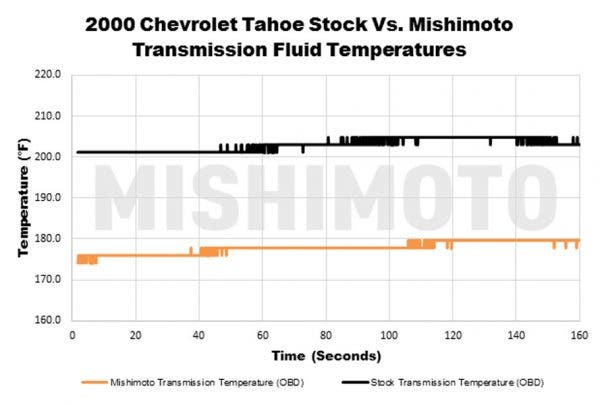

When we were designing the radiator, we noticed that the transmission cooler was located in the outlet tank. That location is a little out of the ordinary. Most manufacturers place the transmission cooler in the radiator inlet so that the heat from the transmission can be dissipated by the radiator. While that method returns lower temp coolant to the engine, the already hot coolant can't take as much heat from the transmission fluid. Our hope was that our radiator would cool well enough to lower both the engine coolant and the transmission fluid temperature.

After logging several trips up and down the hills, we concluded testing with our radiator. But our day was not over. We had data from the Mishimoto radiator, but there was nothing to compare it to. The sun was still high in the sky by the time we arrived back at our facility and the temperature was hanging steady at 79*F. The project engineer quickly swapped out our radiator for the factory radiator and headed back out to establish a baseline. We repeated the same exact testing procedures as the Mishimoto radiator. The engineer was careful to maintain the same speed and the same route as the Mishimoto radiator testing.

The results would prove to be better than we could have hoped for.

Our radiator showed a substantial reduction in every parameter we tested. Radiator inlet temperatures with the Mishimoto radiator were reduced by approximately 20*F over the stock radiator. On the other side, outlet coolant temperatures measured in at approximately 46* below the stock radiator outlet temps. With that great of a reduction in outlet temperature, it's no surprise that transmission fluid temperatures also showed a significant drop. Transmission fluid temps with the stock radiator peaked at around 205*F. With the Mishimoto radiator installed, those temperatures fell to a peak of 180*F and followed that 25*F reduction throughout testing.

Like I said earlier, good design only matters if it works in the real world. It goes without saying that our radiator achieves that. We know it fits like stock and cools even better. So, what's left? For us, the next step is to complete production. For you, it's time for the pre-sale. In the next few weeks we'll be putting this radiator up for sale at a deep discount while we finish up production. If you want your GMT800/900 Silverado, Sierra, Tahoe, Yukon, Suburban, Escalade, Avalanche, or H2 Hummer to stay cool for another 200,000 miles or more, now is your chance.

Thanks for reading,

-Steve