InterCOOLactic Planetary - 2017+ Honda Civic Type R Performance Intercooler Kit R&D, Part 6 - Dyno Testing Results

Investing in an intercooler shows some similarities to going to college. Hear me out. When that acceptance letter arrives, it's understood that there's a lot of money about to be spent as a down payment on the future. Some of us might have held a job or two while in school, but the general idea is complete your degree, and get your dream job, or at least something that is enough to pay off those loans.

A bigger intercooler is an investment in your Civic Type R's future, especially for those who are doing builds and expect big numbers from the K20C1. Depending on the car and the design, adding more fins and surface area to the intercooling system usually gives you some power right off the bat. Our new design does squeeze a few extra drops of power from the CTR, but the main objective is to keep your charged air temperatures down.

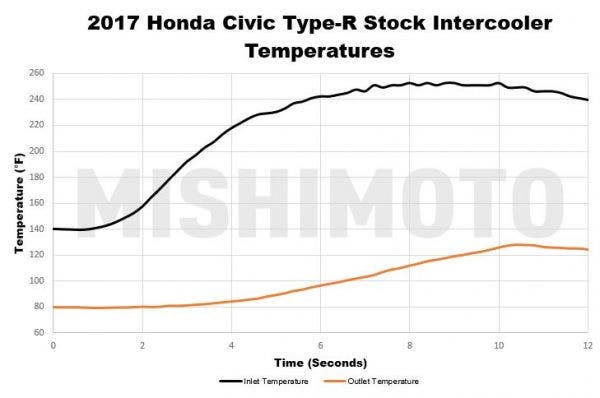

Where the stock intercooler would flunk out from even spirited driving, our intercooler is designed to keep the CTR's GPA up, and its finals week here at Mishimoto. Our engineer, Dan has plenty of testing in store to make sure that it's up to the task. We started with standard power pulls. These single runs give us not only a look as to how well the new core can wick away the heat, but also allows us to record any power increases. For the sake of science, we made sure to run the same tests on our CTR's stock intercooler as well. Here's what we saw with the factory unit.

With Honda's original design, the intercooler's outlet is still very much reliant on the inlet temperatures. Once you put your foot down, the small tube-and-fin design can't seem to keep up.

Just from looking at this graph, it's plain to see that heat takes up residence in the stock intercooler without much resistance. The main effect is that those high temperatures are now being forced into your intake manifold, and aren't nearly as easy to compress. By comparison, here is what our larger core and piping was able to do to keep the charged air temperatures down.

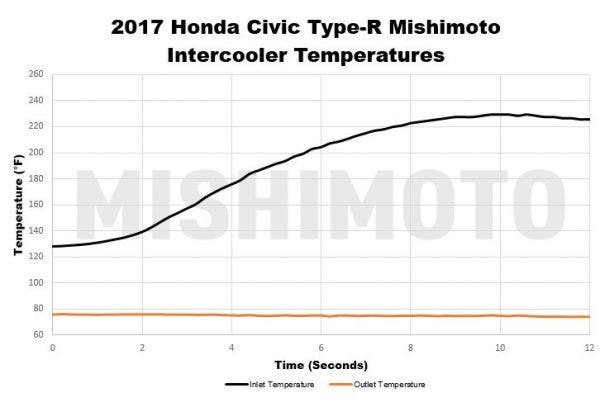

With our new design, the inlet and outlet temperatures are completely independent of each other. The larger and more robust tubes and densely packed fins are able to wick the heat from the charged air much more efficiently.

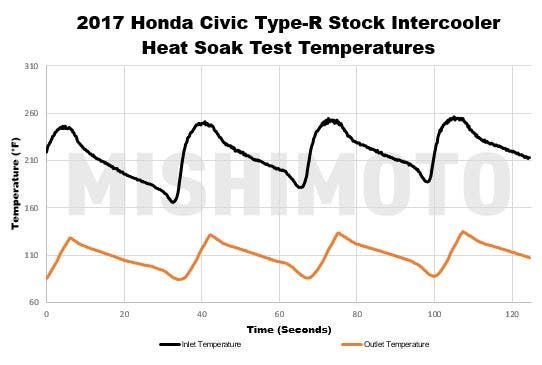

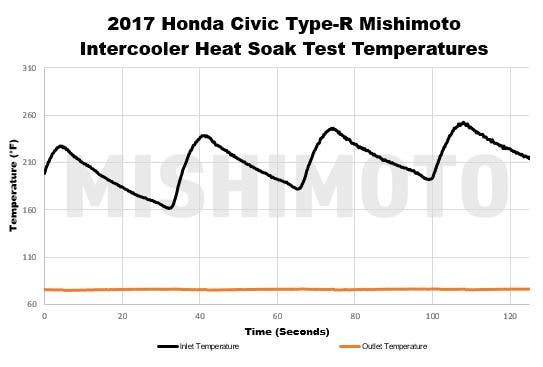

The real difference is apparent when we run our heat-soak tests. Since nobody drives their CTR one power pull at a time, we've devised a way to simulate the effects of demanding driving styles and heat up the core. We run 4 sustained pulls directly after each other, with no break to let the car cool. First up in the hot seat is the stock intercooler.

From this test, we can truly see the dependency between the inlet and outlet on the stock core. While the stock intercooler does show some heat dissipation characteristics, a good portion of the hot charged air still makes its way through the fins.

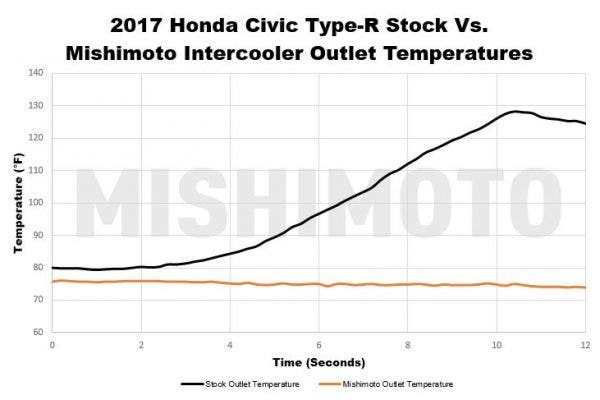

Honda clearly had daily driving in mind when they first developed the CTR's intercooler. The smaller volume, and lightweight tube-and-fin construction make for easy passage of the heat from one side to the other. With temperatures reaching upwards of 140°F from the outlet on a stock tune, the K20C1's performance is going to suffer once you really start putting the hammer down. Unfortunately, we ran our testing before any of the tuning was available, but it's not hard to imagine that the results would be much hotter. For a little insight into what a tune can do to your charged air temperatures, make sure you check out the the data we collected when testing the intercooler for the CTR's little brother. With the stock testing complete, we swapped out the dinky stock core for ours to see what it had to offer.

With our intercooler kit installed, we couldn't seem to get the outlet temperature to budge much higher than the ambient temperatures in the shop. Thanks to the total increased volume, combined with the hefty bar-and-plate construction, our core design was able to intercept the heat before it made its way across the intercooler.

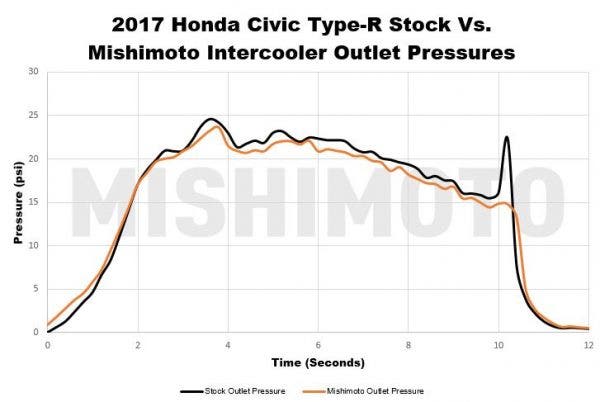

Heat isn't the only thing that our intercooler kit can handle. There's one thing that going to school and the CTR definitely have in common. There's lots of pressure. When modding a turbocharged vehicle, it's all about how to maximize the boost pressure. Luckily, cranking up the PSI on a modern forced induction vehicle is pretty easy by way of a tune, but as we went over earlier, the unwanted side effect is heat, hence the need for an intercooler. If you look back through our design plans, you'll see that going for the biggest possible diameter on the piping and inlet/outlet sizes isn't in the best interest for capitalizing on your boost pressure. Dan made sure to run all the right calculations in order to get the pipe and end tank opening sizes just right. Calculations could only get us so far, so we made sure to measure our boost pressure on the inlet and outlet of both the stock core and our core.

With any intercooler, even stock units, there's going to be some sort of pressure drop. Just the nature of filling the volume and slowing the air enough so the heat can be wicked away reduces the amount of pressure recorded on the other side. You might notice that during our testing we did record approximately 1 PSI of additional pressure drop over the full system, which, given the increased size of the pipes and the internal volume of the new core, wouldn't even cause a noticeable effect on the boost pressure.

Stacked up against each other, the outlet pressures end up looking almost identical to each other, meaning that with our intercooler installed you won't notice much of a difference in boost pressures.

It's here, graduation day for our now highly educated and chilled out CTR. It's a no brainer that the stock unit wasn't up to the task, and our new and improved core was the degree your Type R needed to go even further. After acing the test in temperature drops, crushing the exam in pressure drops, and picking up some credits in the department of power, the CTR is ready to tackle the post-grad life of tunes and bigger turbos.

For an even more in depth look at the development of this intercooler kit, make sure you check out our full length video covering each detail behind the engineering of this product.

Invest in your CTR's future potential toady!

2017+ Honda Civic Type R Performance Intercooler Kit

Thanks for Reading!

-Nick