Cool Air for the EcoBoost - Intercooler Pipe R&D, Performance Testing

These intercooler pipes are now available!

Click here to buy them from our website!

As the old cliché goes, some things just go together like peas in a pod. Peanut butter and jelly. Cold beer and tailgates. Intercoolers and intercooler pipes; you just can't have one without the other. If you followed along with our 2011-14 F-150 EcoBoost intercooler thread, you've probably been waiting for an update on our intercooler pipes for a while now. Well, the wait is over.

Fabrication

In the last post, fabrication ended for our prototype cold-side pipe. Since then, we've been busy fabricating the hot-side piping and testing. Steve and Mike whipped up a hot-side prototype using the same process as the cold-side piping. Steve started by measuring the stock pipes using our ROMER CMM (coordinate mapping machine). Mike then used those measurements to cut and weld a set of prototype pipes.

The two pipes feeding the intercooler air from the twin-turbos are long and intricate, so proper measurements are imperative. As a final check, the welded hot-side prototype pipes went through test-fitment on the truck. After confirming fitment, it was time to go from prototype to production. Steve pulled the hot-side pipes off the truck and mounted them in our ROMER CMM. The data from the CMM allowed Steve to provide manufacturing with accurate 3D models of the hot-side and cold-side pipes. These models become the blueprint needed to produce a sample.

Performance Testing

Fast forward to January. We have shiny production samples of our 2011-14 F-150 EcoBoost intercooler pipes in our shop and are ready to begin performance testing. Before strapping the F-150 to the dyno and running the pipes through their paces, Steve tested the stock pipes on the flow bench. To make sure he wouldn't see any bottleneck from the stock intercooler, Steve mated the pipes to our performance F-150 EcoBoost intercooler. Testing the stock intercooler pipes established a baseline to compare the Mishimoto pipes to.

Steve continued the test by swapping out the plastic mass of hot-side tentacles for our aluminum pipes, while leaving the stock cold-side pipe in place. After noting the difference in flow, Steve then replaced the cold-side pipe with the Mishimoto aluminum pipe and repeated the test one final time. The flow bench revealed a 10% total flow increase with both the Mishimoto hot and cold-side pipes installed. But it's not enough to just flow more air. The true test is in how the truck reacts to that air. It was time to run the truck on the dyno.

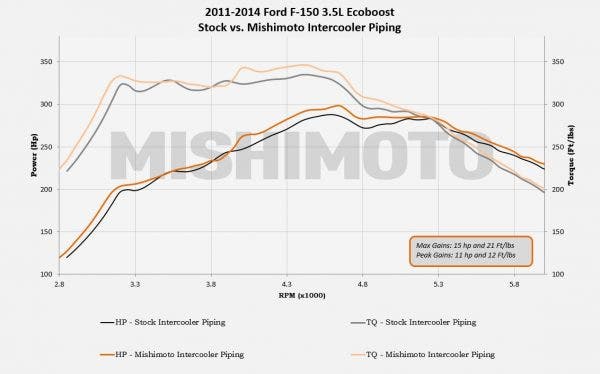

Better flow is great, but the real goal is to produce more power. With an internal volume increase of 41% on the hot side and 34% on the cold side, Steve was confident the truck would be able to translate airflow to horsepower. The stock intercooler was left on so we could be sure that any performance gain would be solely the work of our pipes. After several runs on the Dynojet, the pipes resulted in gains of 15 horsepower and 21 Ft/lbs. of torque.

We now know that our 2011-14 F150 EcoBoost intercooler pipes fit and perform. The last step in this journey will be a pre-sale in the next few weeks. So keep an eye out, and as always, let me know if you have any questions.

Thanks for reading!

-Steve