Refining a Titan- Intercooler Pipe Kit R&D, Part 2: Prototype Fabrication

In our last post, we ended with a rendering of the Nissan Titan XD intercooler pipes and the jig that we plan to use to fabricate them. Since then, we began fabricating our prototypes and testing fitment.

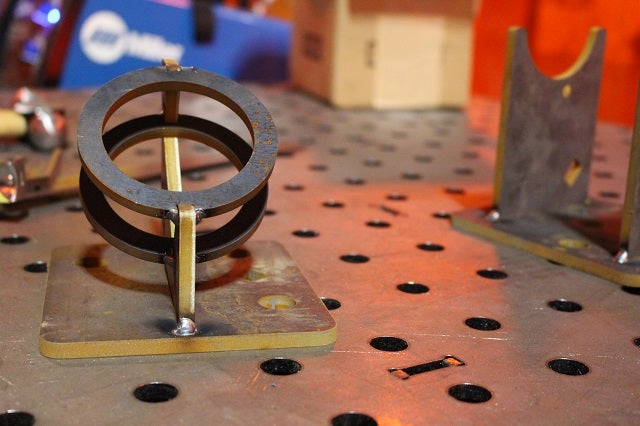

Before we could begin welding our prototypes, we first had to fabricate our jig. With the help of the trusty waterjet, we sliced the pieces for the jig and began assembling them.

Titan XD Intercooler piping jig

Titan XD Intercooler piping jig

Titan XD Intercooler piping jig

Titan XD Intercooler piping jig

With the jig assembled, Mike fired up the welder and got to work on our prototype. Although the measurements that we took with our CMM (coordinate measuring machine) in the last post should be accurate, we tack-welded the pipes first to check fitment on our Titan.

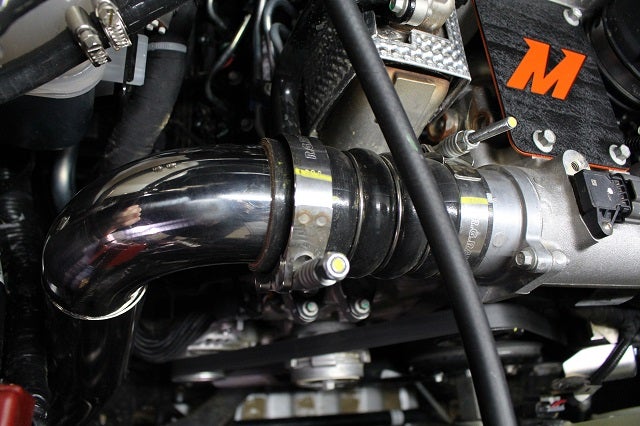

Titan XD stock and Mishimoto intercooler pipe

Titan XD stock and Mishimoto intercooler pipe

Titan XD hot-side intercooler pipe installed

Titan XD hot-side intercooler pipe installed

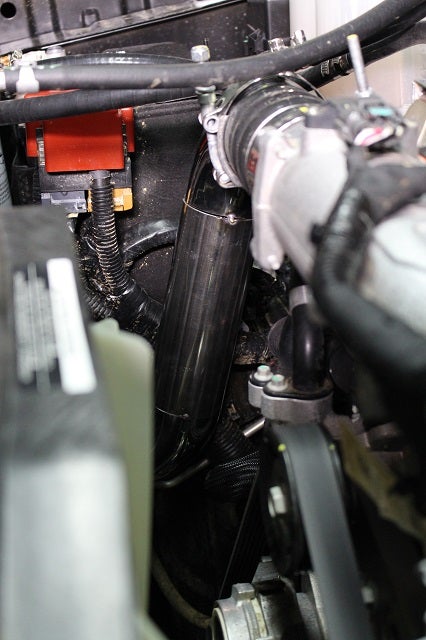

Titan XD cold-side intercooler pipe installed

Titan XD cold-side intercooler pipe installed

Looks like our jig is spot on! With fitment confirmed, it was up to Mike to finish our prototypes.

Fabricating Titan XD intercooler pipes

These awesome aluminum masterpieces are finished! We can all sleep better knowing that our brand-new shop vehicle is sporting these rust-free aluminum pipes. Paired with our DuraCore™ boots, our Titan just got a preventive upgrade that also looks great.

Titan XD Intercooler pipe prototype

Pre-Sale

Now that our development is complete, we are offering a discounted pre-sale for those following our progress. Check out the pre-sale on the Titan XD Pipe and Boot Kit, and let me know if you have any questions.

As always, thanks for reading!

-Sara