Developing A N54 Catch Can Solution, Part 2: Second Prototype Design

Interested in picking up our N54 oil catch can system? Check out more details on our product page linked below!

BMW N54 Baffled Oil Catch Can Kit

E90 Test vehicle engine bay

After evaluating the design of our first prototype and performing some additional research regarding customer needs, we were prepared to fabricate a second prototype. As noted toward the end of our last post, we would be relocating our catch can for easier servicing, and we would also be designing a new catch can lid to accommodate the larger ports for the N54 CCV system.

Catch Can Lid Prototyping

A teaser in our last post revealed the plans we had for our large-port catch can lid. Check out a few more shots of this 3D-printed unit below.

3D-printed prototype catch can lid

3D-printed prototype catch can lid

This lid uses exactly the same mounting bracket and system as our standard baffled catch can, which allows the can to swivel nearly 360 degrees and which provides some adjustment to its mounting. The ports are much larger than those of our standard catch can, which allows us to retain the stock hose diameter and eliminates any chance for flow restrictions due to necking down the lines.

Bracket Fabrication

Our catch can mounting bracket was next on our list for this second prototype. We would be moving this component toward the front of the engine bay. Our goal would be to design a subtle bracket that would retain a factory-like appearance.

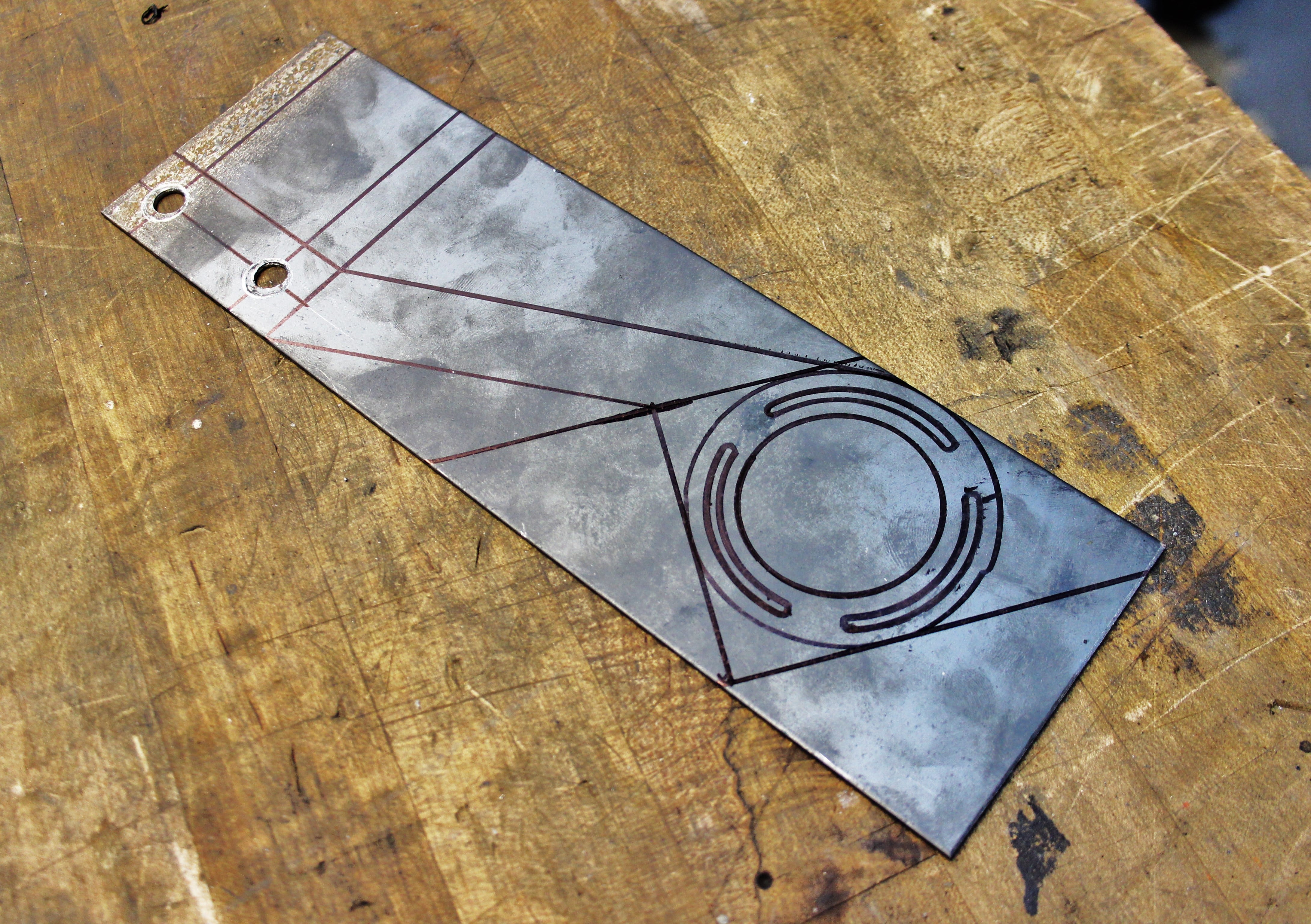

First, measurements were collected from the engine bay, and the mounting points were selected. We would be attaching this to the same bracket that secures the power steering reservoir. We mapped out our design on some plate steel.

Catch can bracket fabrication

Catch can bracket fabrication

Take a look at this prototype mocked into place.

Catch can bracket mock-up

As you can see we are placing this catch can at the front of the engine bay nears the power steering reservoir. This will provide a very easy servicing location compared to our first prototype. Removal of the cowl cover will not be necessary making emptying the can contents a much easier process.

We then cut out our first template!

Catch can bracket

Catch can bracket

Once complete we checked fitment again, made any necessary modifications, and began to put this piece into a 3D-model in our Solidworks program.

We decided to make a few adjustments to this design. First, instead of the slotted can mount shown earlier, we would be simply making three holes to mount the catch can in the proper location. This would require no adjustment necessary by our customers. We would also be putting a few bends into the bracket and adding bracing for an improvement in support and rigidity.

Check out this second design!

Catch can bracket fabrication

Catch can bracket fabrication

Catch can bracket fabrication

Catch can bracket fabrication

A splash of paint, and this bracket was ready for installation!

Catch can bracket, final design

Catch can bracket, final design

Coming Up!

Check back next time for a look at our CNC-machined catch can lid!

Thanks for reading!

-John