Mishimoto 2010-2012 Dodge 6.7L Cummins Intercooler, Part 5: Testing Results and Project Conclusion

Interested in purchasing this Cummins Intercooler? Check out our product page for more information!

Mishimoto Dodge 6.7L Cummins Intercooler

Finally, the results are in! The testing of our 2010-2012 Cummins Performance Intercooler is complete. After months of development and weeks of testing, our team was extremely excited to crunch the numbers to see how our cooler compared to the stock unit. Before we jump into the actual data pulled from our dyno pulls, we will first compare the physical attributes of the Mishimoto cooler to the stock unit.

Intercooler Physical Comparison

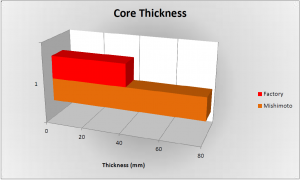

First, our comparison of overall thicknesses of the stock and Mishimoto cores. This difference was displayed in an earlier post where we showed the actual measurements.

Stock vs Mishimoto intercooler core thickness comparison

As seen in the chart above, we are doubling the thickness of the factory cooler. Due to the design and placement of the intercooler, AC condenser, and radiator, we were able to expand this unit quite significantly. By adding core thickness, we can increase the core volume, which directly affects heat transfer. Greater volume results in more contact points for heat transfer, which ideally results in lower intake temperatures, along with lower EGTs.

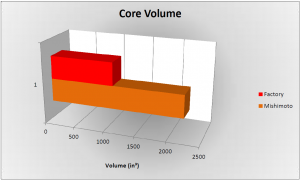

Now that we've referenced volume, let's check core volume to put a number behind our improvements.

Stock vs Mishimoto intercooler core volume comparison

This is the huge increase we anticipated. The Mishimoto intercooler provides a massive 52% increase in overall core volume compared to the stock cooler. This volume measurement includes both external passages and internal air passages. We have improved both internal air volume as well as external fin area. Both of these increases will certainly affect cooling efficiency.

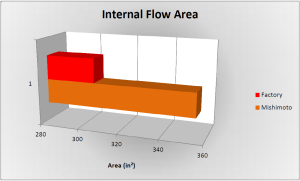

Another interesting figure to consider is the internal flow area, which in the stock cooler comprises the volume inside the individual tubes. Our cooler is composed of a bar-and-plate core, which means we will be measuring the volume within each internal passage. Check out the comparison plot below!

Stock vs Mishimoto intercooler internal flow area comparison

In this plot, we see an increase of 14% compared to the stock cooler. As with the other data noted above, this improvement should result in increased cooling efficiency.

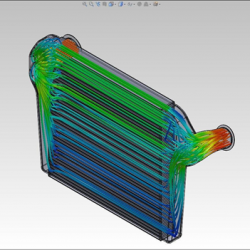

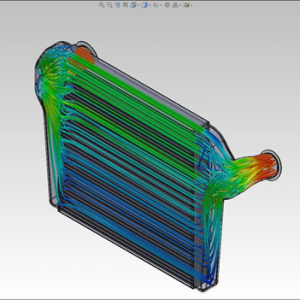

The flow properties of a heat exchanger is another important factor. Ideally, a passage should have unrestricted flow within the end tanks, and with as little turbulence as possible. Smooth airflow will result in less pressure drop across the core, which in turn results in less stress on the turbocharger. One of the key things we look for when designing an end tank is how air is dispersed throughout the entirety of the core. Our goal is to push airflow through the entire height of the core to take full advantage of all the heat transfer points. By creating smooth sloped tanks, our team has provided optimal flow throughout the core. Check out a screenshot from CFD testing below!

Mishimoto intercooler CFD testing

The lines are a graphical representation of airflow. The line color denotes the velocity of air at that point in the cooler: red (highest velocity), yellow, green, and blue (slowest). By using this software, our engineers were able to tweak our end tank design slightly for better results. This is an example of how we use every tool possible to provide an awesome product!

So, how did this intercooler perform during our actual dyno tests? Read on!

Dyno Testing Results

If you recall from our previous post, our test truck was slightly modified (intake, exhaust, tune), and we performed back-to-back testing on our Dynojet. Each run was conducted following a four-minute break for cool-down, and we also swapped the coolers with the truck still strapped to the dyno to avoid any additional variables in testing. Our goal is to provide the most-accurate data possible. We made each pull in 6th gear, starting from 1,800 rpm to 3.200 rpm. Ambient temperatures were rather mild during testing, with a range of 70°F-76°F. Let's check out the plot from the Mishimoto cooler!

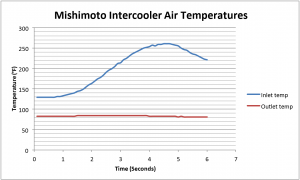

Mishimoto intercooler air temperature

The pull is rather quick from, 1,800 rpm to 3,200 rpm, just a quick five-second burst. Inlet temperatures begin at 130°F and quickly rise to 260°F before settling down to around 220°F. Now, outlet temperature is where we can see the true effect of our heat exchanger. Outlet temperatures start at around 81°F, rising to 85°F, only to settle back down to the original 81°F. This heat exchanger seems not nearly challenged by these dyno pulls on a truck making 700 wtq. We are dropping outlet temperature to nearly ambient temperatures (within 5°F -10°F), which is generally where our diesel intercoolers perform.

So how does this compare to the stock cooler? We saw a 5% reduction in outlet temperatures, which equates to a drop on average of 8°F throughout the pull. Although this does not seem significant, the gains are still quite impressive considering that we achieved close to ambient temperatures. So what do we learn from this? First, the factory cooler is quite efficient for stock or slightly modified vehicles. That being said, there is certainly still room for improvement, as shown with our testing.

Also, consider the fact that during our tests this truck is without appreciable load. Ideally we would perform a similar test during a longer drive with some form of bed load or trailer load to see the effect on temperatures. With additional engine load comes additional heat, which is guaranteed to affect inlet temperatures and truly test the efficiency of a heat exchanger. Our hope is that in the future we will have a vehicle available in a warmer climate, with some form of a load to complete a more relatable test for those who use their trucks for towing/hauling on a regular basis. We have already been speaking with a few 6.7L owners to see if this would be something they would be interested in. If you are local to Delaware interested in such a test, please contact us!

Now that we have positive physical and dyno testing data, we are fully prepared to release this product and begin mass production. Our engineers are confident that the improvements shown in the Mishimoto intercooler will certainly provide greater cooling efficiency for stock and modified trucks in any given environment or driving situation. Before we put an official close on this project, we need to follow-up with our goals and ensure that we met all the needs of our consumers, and followed the paths our research team laid out for us. Check out the recap below.

Project Recap

Project Objectives

- Enlarge core as much as possible for improved flow and heat-transfer characteristics.

Our engineering team enlarged this core by 100% compared to the stock unit, easily achieving this goal. This core enlargement will certainly result in an improvement in both flow and heat transfer, thanks to the additional contact points between fin airflow and internal air.

- Use bar-and-plate core for improved efficiency.

Check! The Mishimoto intercooler utilizes a dense bar-and-plate core for optimal heat transfer and durability. Although heavier than the sock core, the Mishimoto unit will provide huge benefits in AIT cooling efficiency and EGT reductions.

- Improve flow of end tanks.

As seen in our CFD image above, our engineering team paid very close attention to the path of airflow for our cooler. Our goal was to provide the least amount of restriction within the endtanks, while forcing air to disperse to the full height of the cooler. By pushing airflow to the entire core, we can maximize the use of all the added volume our team added to the core. We also designed our intercooler with cast end tanks, which provide a smooth internal surface, reducing the chances of turbulation that can affect flow significantly.

- Must fit into place just like the OEM and require no vehicle modification.

Our thorough test fitting of this cooler proved that all stock mounting points align, and the intercooler drops into position just like the stock unit. Our team confirmed that stock equipment and shrouding bolts fit with this intercooler perfectly, requiring no vehicle modifications. Additionally, we also test fitted this intercooler with both the stock and Mishimoto radiator to ensure compatibility.

- Collect real-world data on cooling efficiency compared to the stock core.

Our team collected a ton of data from dyno testing of this intercooler. Testing data showed that our cooler provides a 5% decrease in intercooler outlet temperatures on a truck with 355 whp and 700 wtq. The Mishimoto intercooler was able to reduce temperatures to within 5°F -10°F of ambient. Although these gains are fantastic, we do anticipate an even greater efficiency increase when the truck is under a load such as during towing/hauling. Our hope is to test this theory at some point during the warm-weather season in 2015. Based on our current testing, as well as the physical attributes of our intercooler design, our engineers are confident that our product will outperform the stock unit during all forms of operation, in any climate, and through any driving situation.

Alright, that wraps up our time with this intercooler. Our team is pleased to report an extremely efficient product that will provide substantial cooling benefits whether you drive your truck daily or use it for towing/hauling. If our team continues to finish projects in such a timely manner, we should be starting product development for the 2013+ 6.7L in the near future!

Thanks for taking the time to follow the build of our intercooler!