2007-2011 BMW E90 335I/135I Performance Aluminum Radiator, Part 2: First and Second Prototype Designs

Interested in purchasing this E90 radiator? Check out our product page for more information!

BMW 335i/135i Performance Aluminum Radiator

Welcome back! While I am sure you haven't slept in days, anticipating the next edition of this thread, the team at Mishimoto has been hard at work. Two, yes two, initial prototypes were developed and one selected to move forward with testing. We won't extend the wait any longer, so check out prototype number one below.

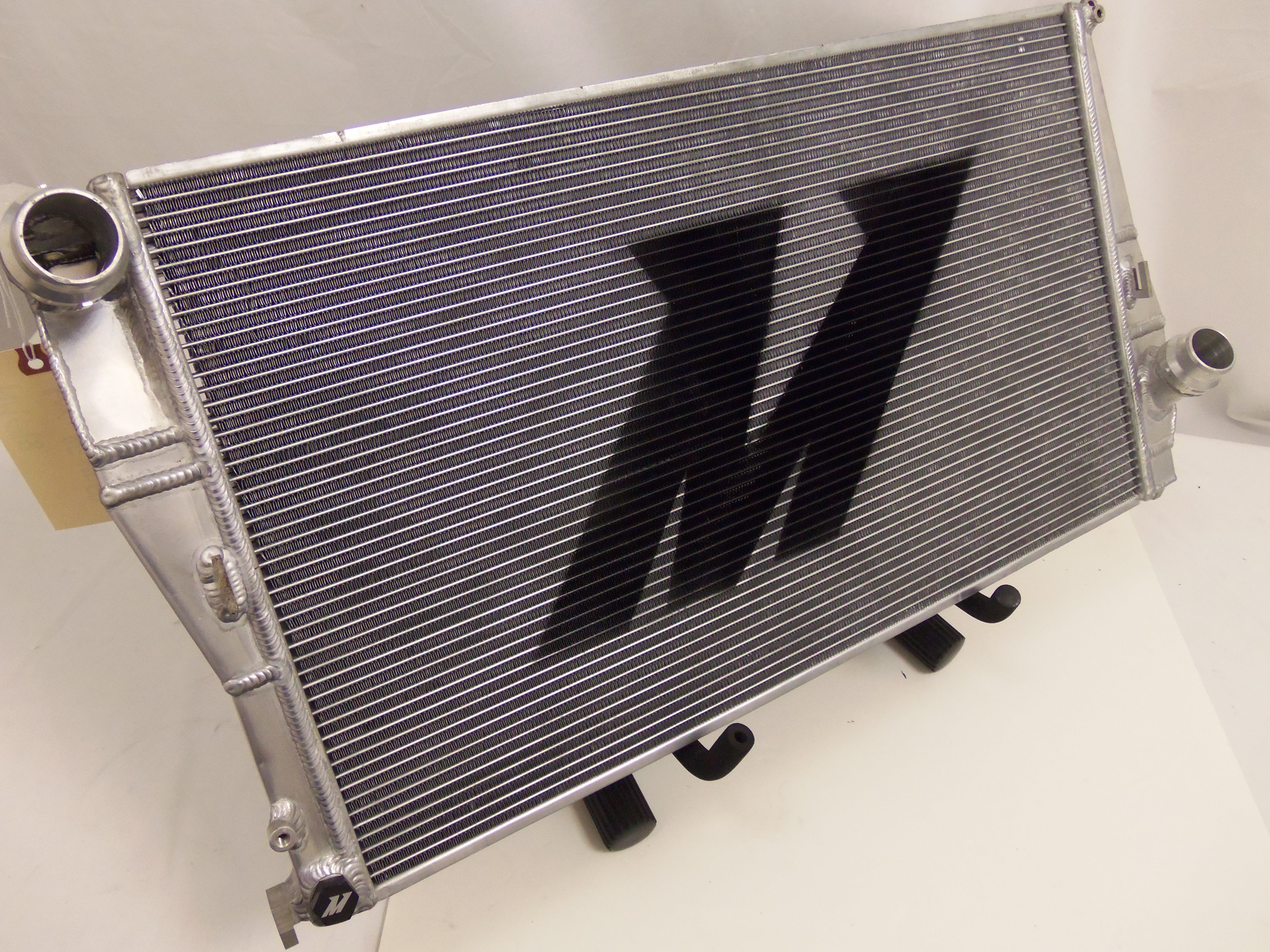

Mishimoto E90 radiator prototype 1

Mishimoto E90 radiator prototype 1

Mishimoto E90 radiator prototype 1 inlet

Mishimoto E90 radiator prototype 1: end tank

This rad is aluminum, and it features a fairly thick core and some pretty well-made quick-disconnect inlets. Keep in mind that this is a rough prototype, lacking the polish and showmanship of a mass-produced unit. At this time we are simply moving towards a final design. The end tanks are very robust and the welding is well done. Using our factory hoses, we confirmed that the quick disconnects function perfectly. All mounting positions appear to be well done, and the general consensus is that the design is adequate. But at Mishimoto, adequate does not cut it. The issue with this unit was not entirely with the end tanks, CNC components, or mounting points. The core design for this particular radiator was rather thick (nearly 10 mm more than the factory unit); however, the fin density was equal to that of the factory unit. Check it out below.

Mishimoto E90 radiator prototype 1: fin density

We didn't know how this would impact real-world cooling, but we knew it would need modification. The core design, fin pitch, and height were modified to provide greater density than the factory unit, but now we were concerned about potentially reduced airflow. With such a dense core, airflow pulling from the electric fan could be limited, so we needed to test this possibility with our new E90 radiator. Specifically, we would need to conduct extensive testing on fan airflow at idle conditions, through both the factory core and our prototype, to be sure it would not affect fan cooling. Enough with the discussion; check out our next prototype design.

Mishimoto E90 radiator prototype 2

Mishimoto E90 radiator prototype 2

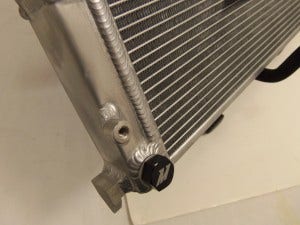

I know exactly what you are thinking: Mishimoto, please release this tomorrow so I can put this beautiful radiator into my car. If only the design of these products could happen so fast! Keep in mind, we still had to fit this into the car and collect performance and cooling data. A good looking product is worthless if it can't keep your car cool, and we want to do our best to keep your E90 on the road instead of spewing fluids on the side of the highway. You will notice that we enhanced a few other aspects of this product while we modified the core. The end tank design features a new construction method, which provides a cleaner look and is much more precise. The CNC-machined components remain the same for this new design. The biggest change, as mentioned before, is the core. We have tightened up the pitch, shortened the fin height, and added additional coolant tubes. Check out the new core design compared the OEM core.

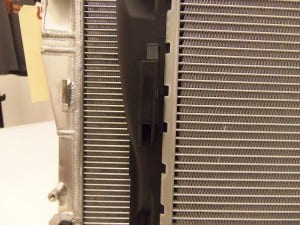

Comparison of cores: Mishimoto E90 radiator prototype 2 (left) and stock radiator (right)

Comparison of cores: Mishimoto E90 radiator prototype 2 (top) and stock radiator (bottom)

This is a huge improvement over both the previous core and the stock core. Now check out the thickness below.

Mishimoto E90 radiator prototype 2: core thickness

This core is 40.5 mm in thickness, more than 8 mm thicker than the factory unit. Our initial vehicle measurements indicated this would be the maximum thickness before we begin to run into fitment issues with other factory components. After seeing the improvements in core density and size, we were pretty excited to see the performance benefits compared to using the factory core. Much of the welding you see here is robotic, providing unmatched consistency and perfectly straight welds, which reduces our rate of defects significantly. Check out a few more shots of this awesome radiator.

Mishimoto E90 radiator prototype 2: end tank

Mishimoto E90 radiator prototype 2: inlet

Mishimoto E90 radiator prototype 2: inlet

Now that this prototype was ready to rock, we needed to complete a few more tasks. For a test fit we would need to drop this radiator into a stock vehicle to be sure that all factory components work perfectly and require no modification. We would check that the hoses fit correctly, the fan shroud bolts to the radiator, and be sure the radiator fits the mounting locations of the stock unit.

Once the test fit is complete, we would collect and evaluate performance. If everything checks out at that point we should be ready to begin manufacturing these radiators and preparing them for purchase!

Stay tuned for the next portion of this write-up!

Thanks