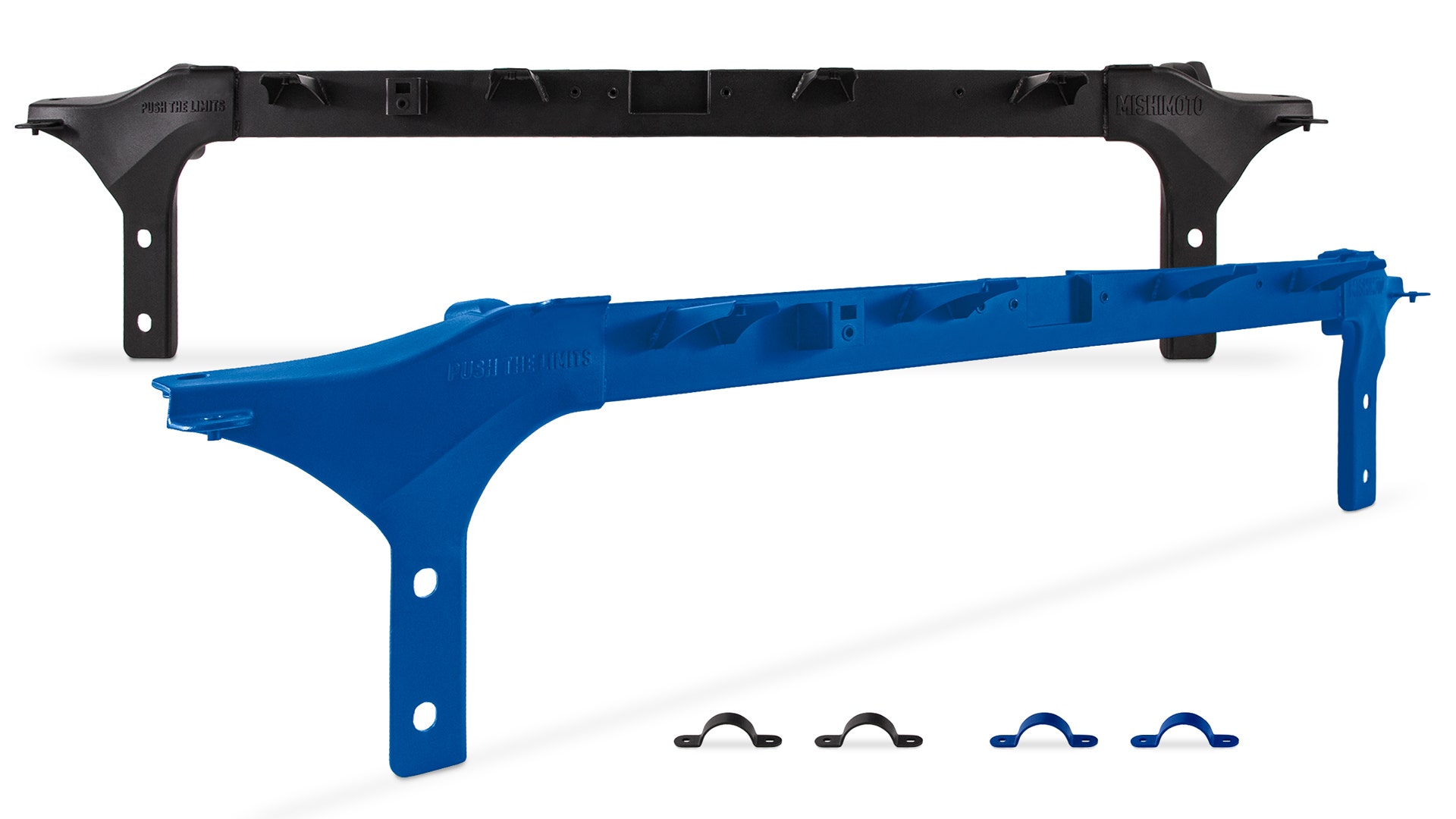

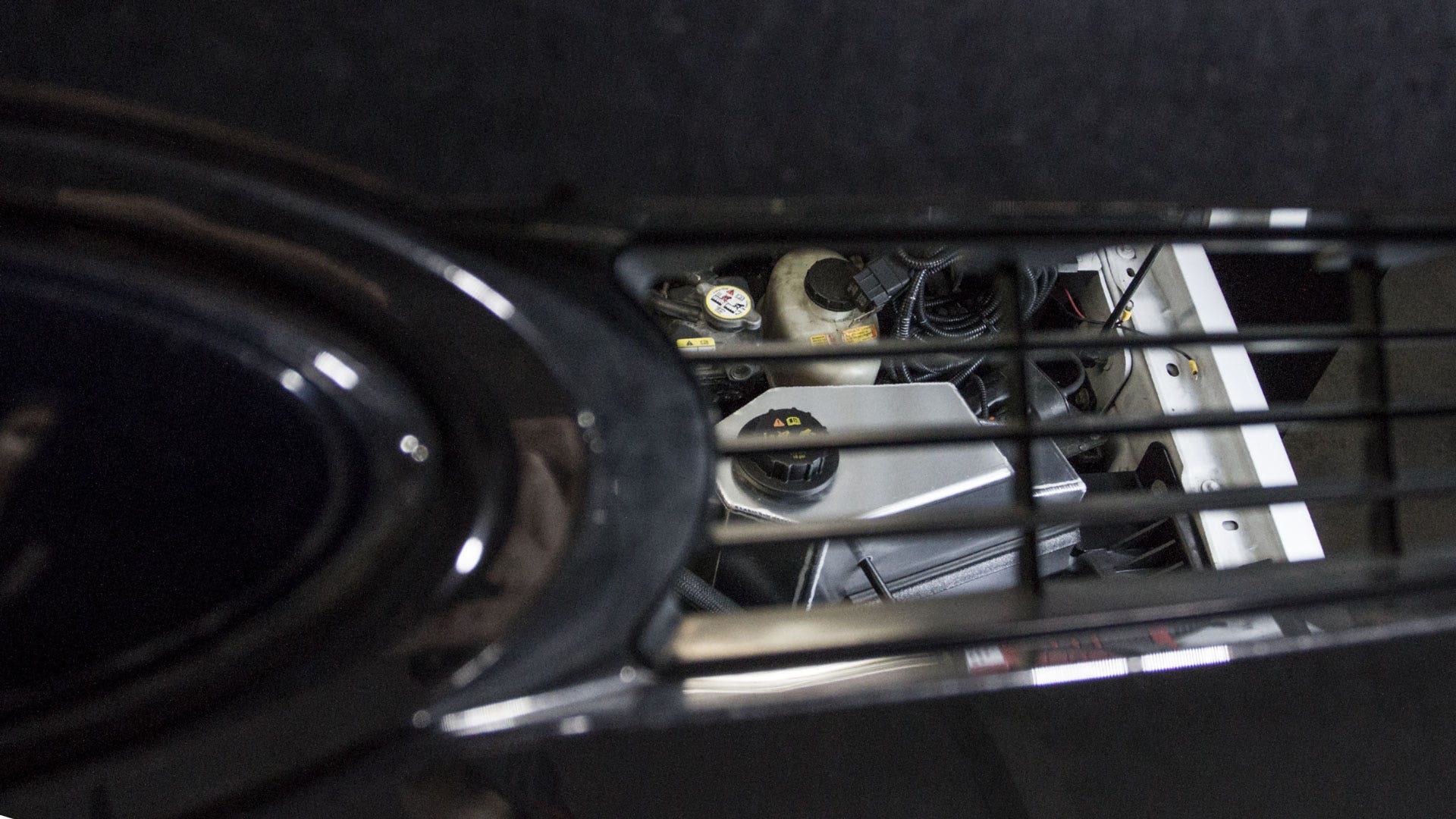

The goal was simple: take what we learned from developing our 2008-2010 6.4L Powerstroke upper support bar and apply it to the next generation 2011-2016 6.7L Powerstroke.

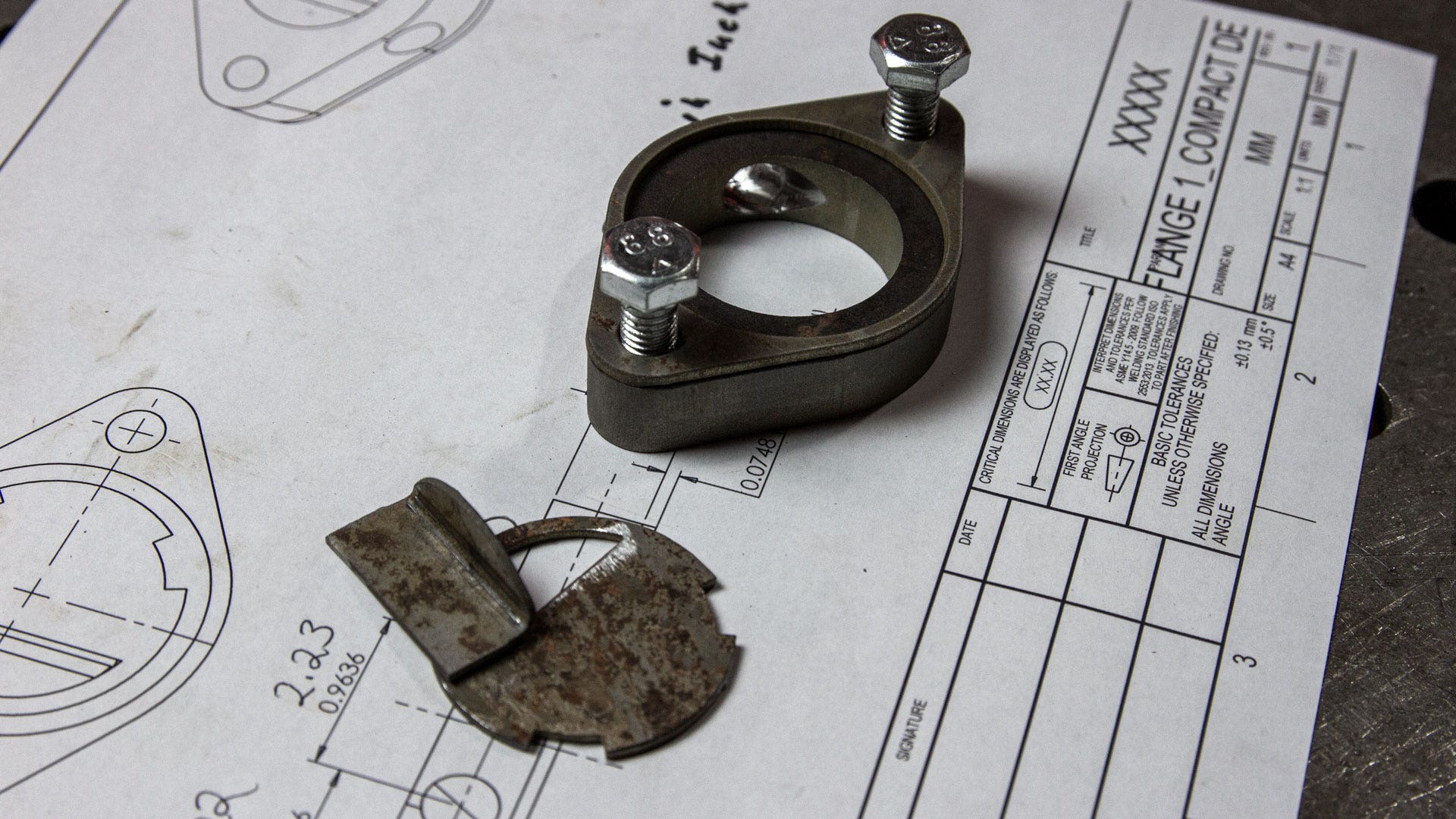

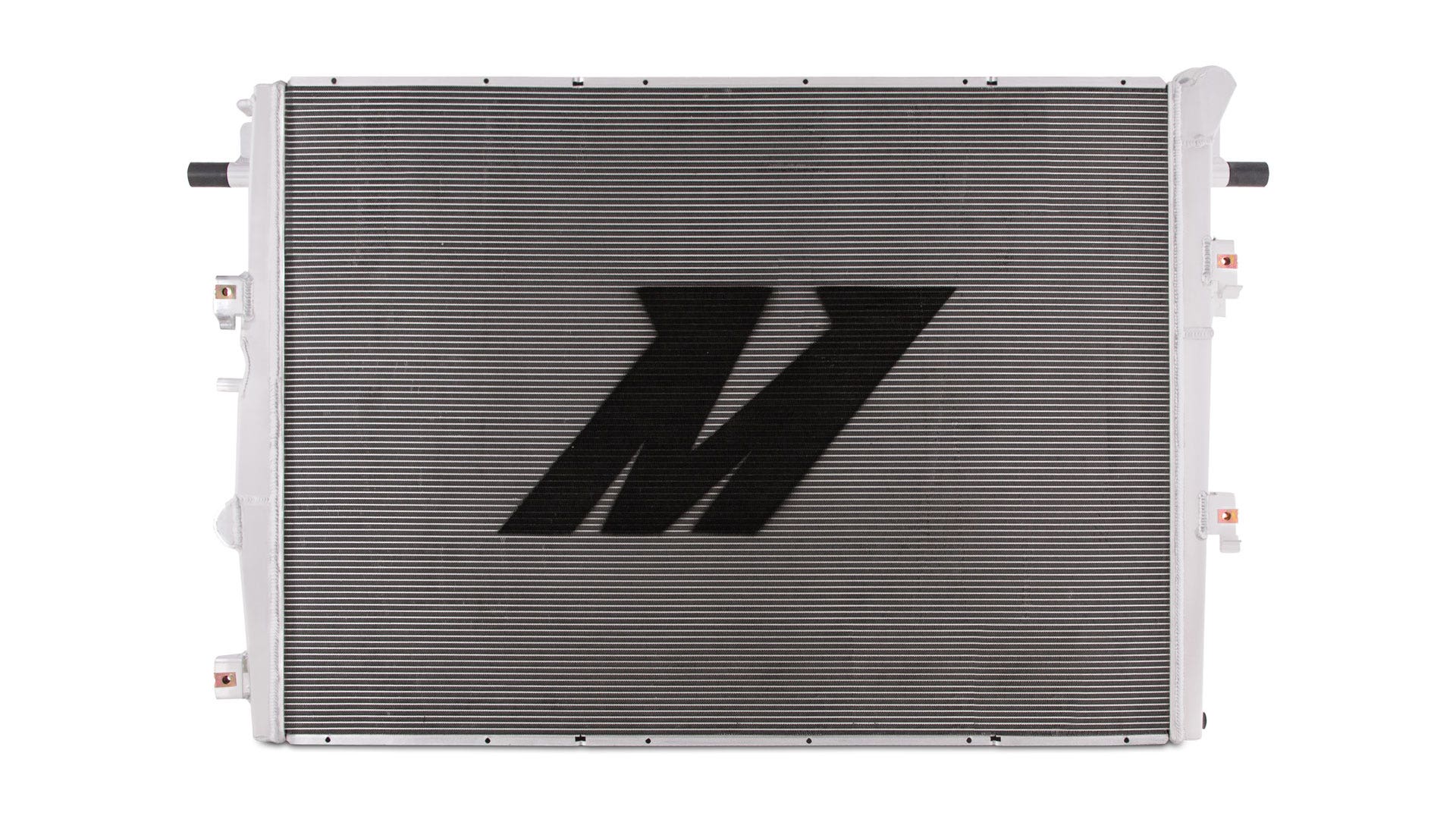

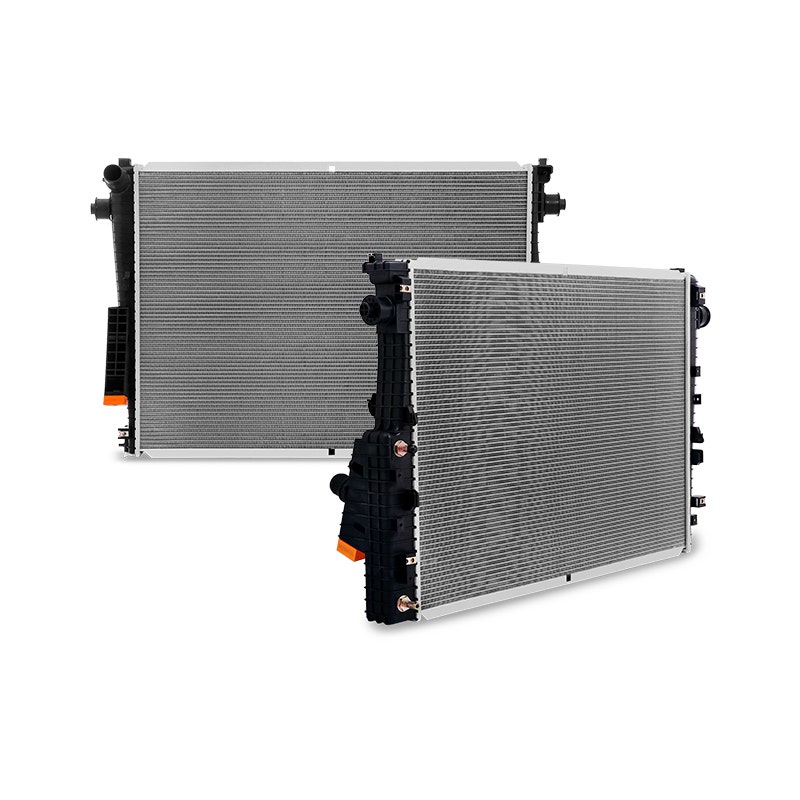

A little over two years ago we dove headfirst into developing our 2008-2010 6.4L Powerstroke upper support bar. Since then, we've been developing more products for trucks and the Powerstroke platform. With every project, two points ring clear. First, Powerstroke owners need a truck that can be powerful and reliable above all else. Second, nothing destroys a heat exchanger faster than flex. We can add as many safeguards against core stress as we want,