Going the Distance - Aluminum Degas Tank, Part 3: Prototype

One of the hardest aspects of design is often knowing when to stop and take a step back. Failure is never fun, but we've learned that failure is just the beginning of a better design. Nothing is a complete failure, it's just another step forward.

When we last saw our 2008-2010 Ford 6.4L Powerstroke aluminum degas tank, it had become a mess of extra parts that didn't add any value for our customers. Thanks to Ford's design team, who apparently didn't know when to stop, our degas tank was trying to be a degas tank, battery tray, and vacuum chamber. All of this was in an attempt to keep our customers from having to cut their degas tank from the battery tray. After building a prototype that combined all three components, we decided to change course. All the extra components had turned our simple degas tank into an expensive monstrosity. We turned to the forums for some perspective.

We asked our future customers if they'd be willing to cut their degas tank from the battery tray, and the overwhelming response was, "yes." Luckily, our engineer saw this as a possibility from the very beginning. If you look at our original 3D-printed prototype, you'll see that the degas tank was designed as a separate component bolted to the battery tray. That original plan made adapting the degas tank to work with a cut battery tray much easier. The tank design did not have to change much, aside from a few small tweaks to the mounts. However, to seamlessly mate our degas tank to the battery tray, we needed another piece to mate the two together.

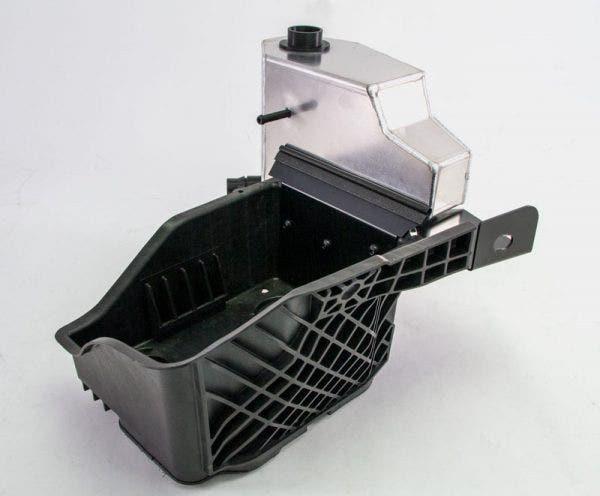

Because our prototype tank fit well, and the overall design wasn't changing, we turned to our fabricator to recreate an aluminum tank. While the degas tank was being welded together, our engineer designed a small piece that would mate our degas tank to the battery tray. This simple plate will hide the cut line, making the degas tank blend nicely with the battery tray. Once our fabricator finished welding the tank and adding a few 3D-printed features, we fired up our cutoff wheel to separate the stock tank from the battery tray. After the plastic dust settled, we bolted it all together and our revised prototype was finished.

Our first attempt at creating an aluminum degas tank, battery tray, and vacuum chamber was what could be considered a failure. But like I said earlier, failure is just the beginning of a better design, and that holds true for our 2008-2010 Ford 6.4L Powerstroke degas tank. Our new design is clean, simple, and fitting. In the next post, we'll see how it looks in its final production form.

Thanks for reading!

-Steve