Protect the Lifeblood - Performance Oil Cooler R&D, Part 1: Stock Review

Oil is the lifeblood of any engine; without it, the engine would self-destruct in a matter of seconds. But just having oil in the engine isn't enough. It needs to stay just the right temperature too. Modern synthetic oils can withstand temperatures up to about 350°F, but as engine temperature climbs, oil begins to thin and lose some of its protective properties. There's a sweet spot where oil is most effective: thin enough that it can flow into the tiny crevices of the engine, but thick enough to cushion the blows of combustion.

For a heavy-duty diesel engine like the 2011-2019 Ford 6.7L Powerstroke, ensuring the oil stays in that sweet spot is essential. Heavy towing or power-adding modifications can quickly drive oil temperatures over the useful range, sucking the life from the 6.7L's internal components. To help combat high oil temperatures, Ford equipped the 6.7L Powerstroke with a liquid-to-liquid oil cooler from the factory.

The stock 6.7L oil cooler is a simple design that uses the engine coolant to warm and cool the oil. The inside of the cooler is separated into two sets of fins. Oil flows through one set of fins while coolant flows through the other. In cold climates, the coolant heats up faster than the oil. In these situations, contrary to its name, the oil cooler ensures the oil warms up quickly, allowing it to flow throughout the engine efficiently. Once the oil temp exceeds the coolant temp, the coolant helps pull excess heat from the oil and releases it through the radiator. The stock cooler is adequate for a stock truck, but with more power comes more heat, and the stock unit starts to fall short.

The first and most obvious limitation is that the stock cooler relies on the engine coolant to draw heat away from the oil. This setup works well up to a point, but the coolant temperature can rise well over 210°F during heavy towing. When that happens, the radiator is doing everything it can just to cool the engine, and the coolant can't carry much thermal energy away from the oil. The inverse is also true; the heat from the engine oil puts more load on the coolant system, keeping it from reaching peak efficiency.

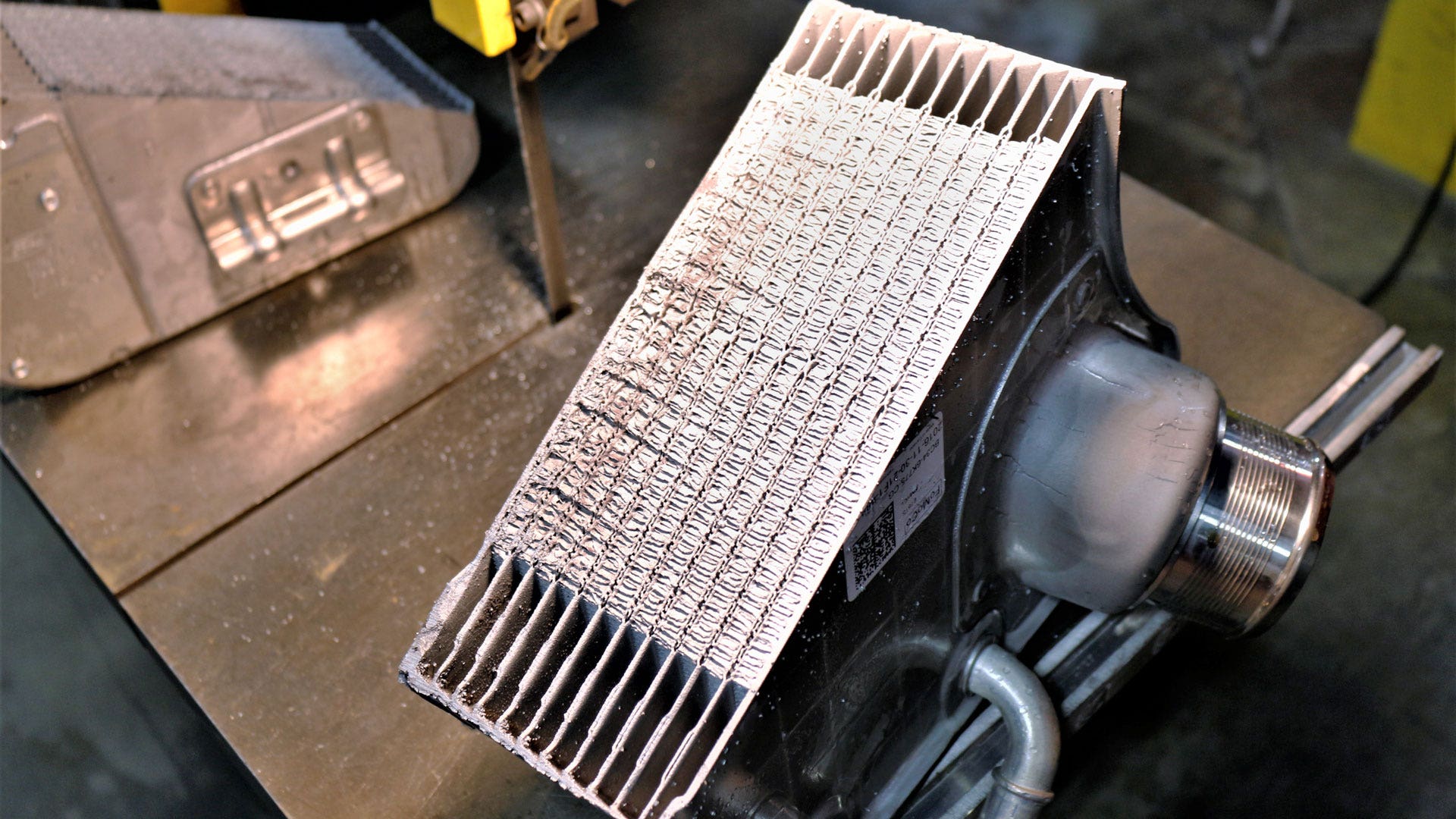

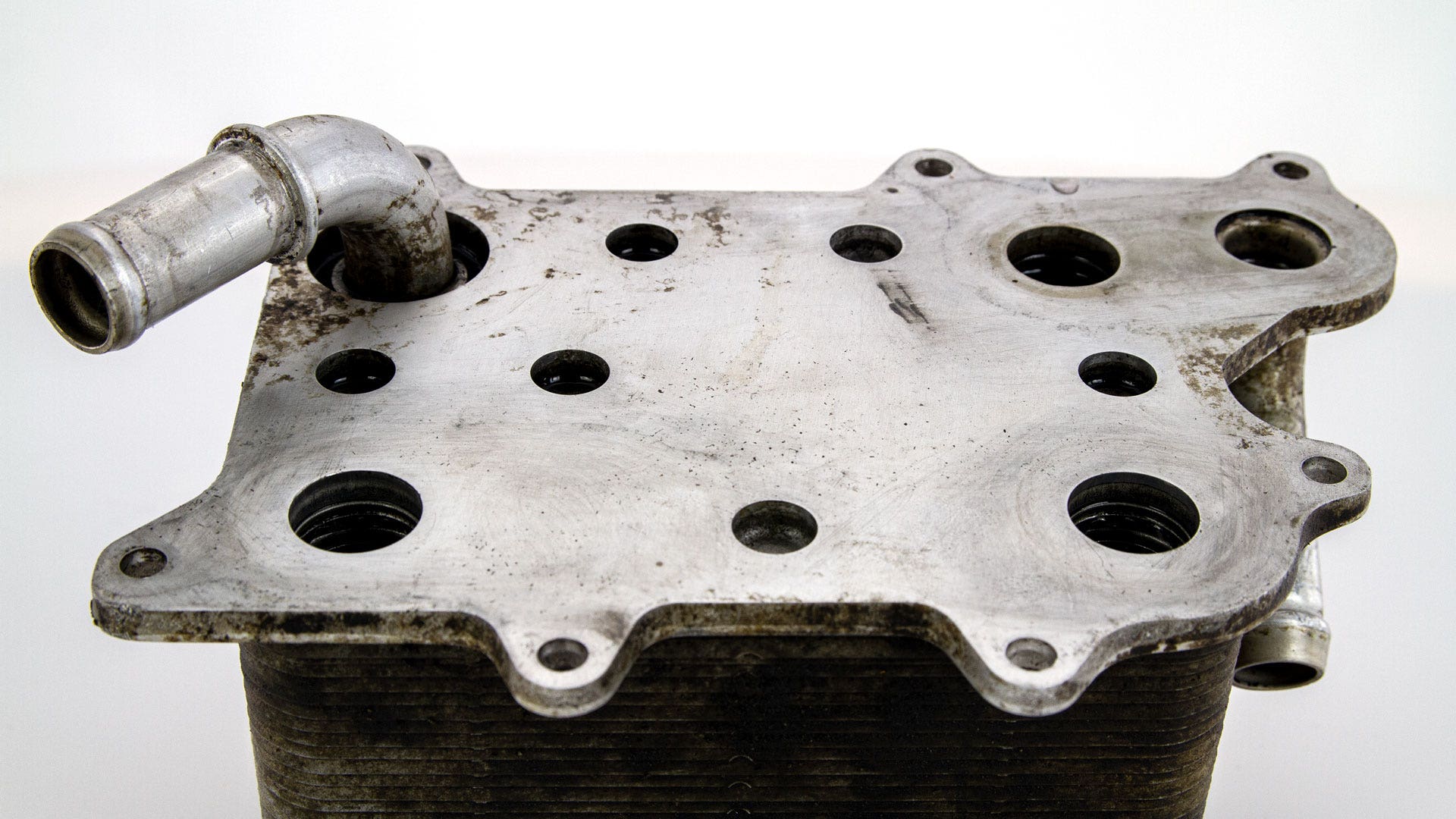

The second issue with the stock cooler may not be as noticeable right away, but given enough time, it can prove disastrous. The stock cooler is what's known as a "stacked plate" cooler. Stacked plate coolers are made by sandwiching layers of fins in between plates, then brazing it all together. The fins are sealed off from each other in an alternating pattern to create two chambers: one for oil and the other for coolant. The issue with this construction method is that the cooler expands and contracts as the temperature of the fluids within it rise and fall. Over time, that movement can cause the brazing between the plates to crack, leading to leaks. We saw similar issues on the stock 6.7L air-to-water intercooler that also uses a stacked-plate design (below, right).

Luckily, we here at Mishimoto are ready to tackle these issues, and we're doing so by eliminating the connection between coolant and oil. To help take the load off of the cooling system and cool the oil as effectively as possible, we'll be removing the liquid-to-liquid cooler and replacing it with a liquid-to-air cooler. But this won't be as simple as plumbing a few lines and making a bracket. The 6.7L flows a massive amount of oil, and the stock cooler is attached directly to the engine block. That means getting the oil to our cooler, without causing a fluid traffic jam along the way, will be a challenge. In the next post, we'll look at how we plan to overcome that challenge and show you our initial design. So, keep an eye out for the next update, and as always, let us know what you think.

Thanks for reading!

-Steve