If you remove the body from your 2011-2019 Ford F-Series Super Duty, you'll be left with less of a truck chassis and more of a factory. This assembly line is spec'd out for one product, made to order torque shipments, and you're the primary customer. Like a non-truck-based factory, the process is a group effort, with every component depending on each other to create the final product. The 6R140 TorqShift transmission mated to the 6.7L Powerstroke is the torque factory's distribution wing, and we felt that it was time for an expansion.

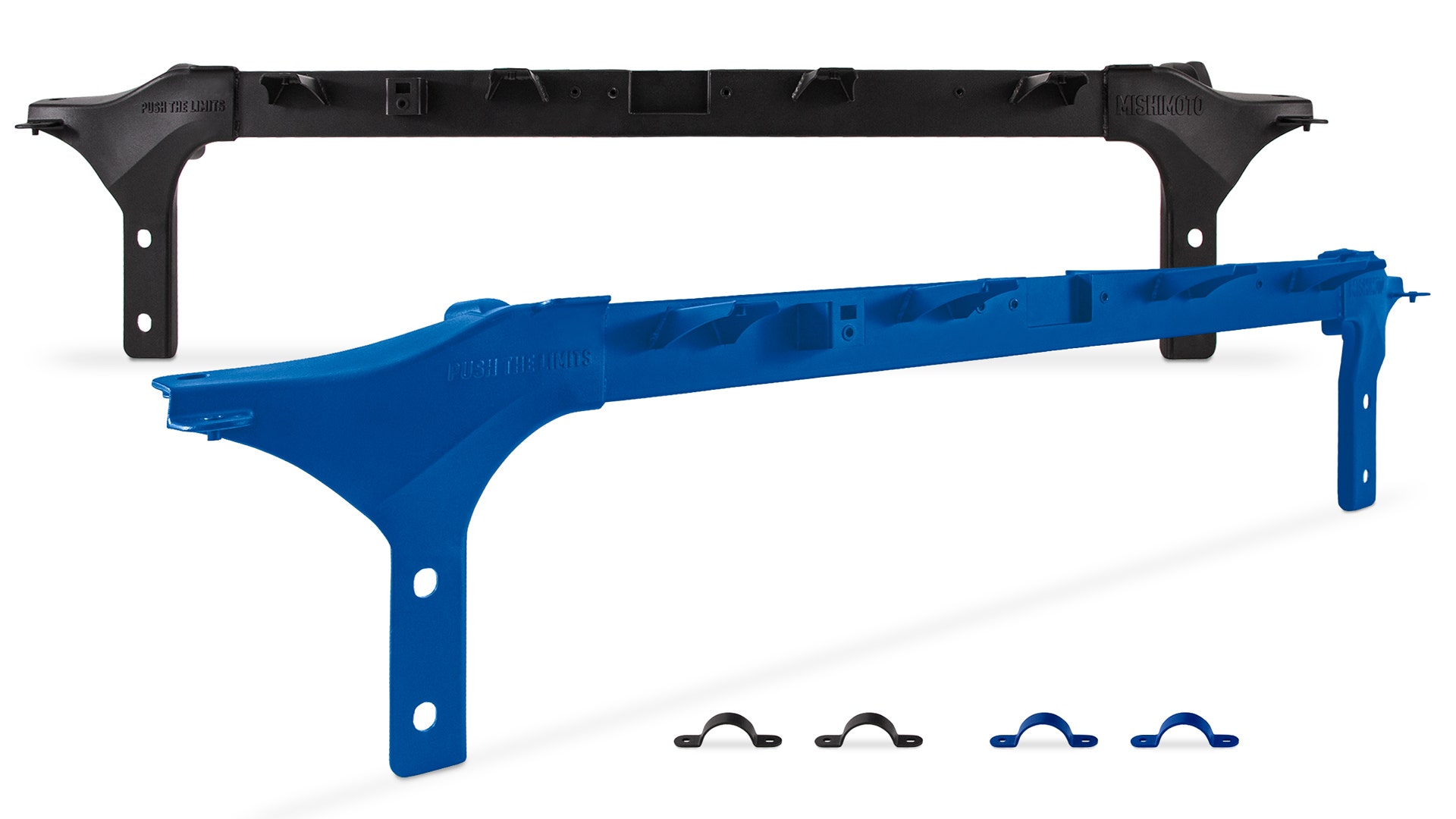

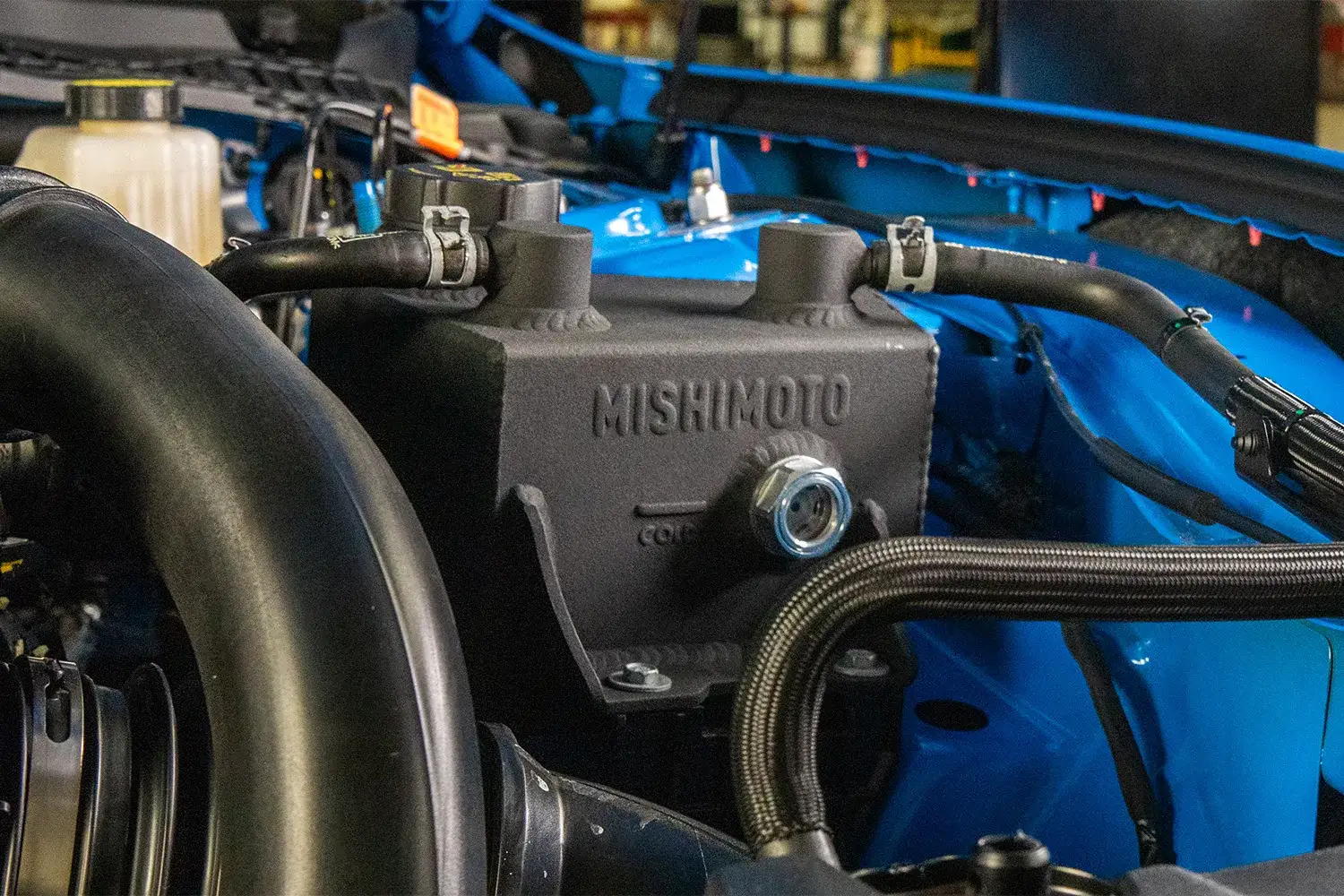

It's no secret that Ford's Super Duty trucks are towering metal machines, which require massive amounts of cooling. The stock liquid-to-liquid transmission cooler provides adequate cooling in a compact package, but it has its limitations. Some Powerstrokes need extra cooling power, especially when it comes to towing or hauling a heavy payload. We already went over this concept in our last post, so let's dive into our final production-level transmission