Requesting Backup - Secondary Race Radiator Prototype and Testing

The FK8 was designed to be a road warrior. From the twisty mountain backroads to the most Ivy League of race tracks, Honda built this Civic to dominate the tarmac. Even with its inherent skill and teeming aggression, the Civic Type R still comes under fire from the heat it produces. There's nothing more frustrating than having to cut your track day or canyon run short when the car that Honda designed for just such driving gets pinned down from high temperatures. Looks like this Civic could use some backup, maybe something like a secondary race radiator.

"Why not just make a performance radiator?" is the question I'm sure many of you are currently asking. Radiators are, in fact, our area of expertise. The K20C1 is nestled close to the front end of the 10th generation Civic. Combine that with the front-mounted turbo and the potential build envelope that is already critically limited, and there's only a handful of directions to go. Even with adjusting the fin density and pitch, we would expect to see similar results as the stock setup. Knowing this, our engineers got creative.

Did We Mention the

Aero?

It's no secret that aerodynamics was a clear focus with the FK8. I might have mentioned something about the myriad of vents, splitters, and towering wing on the back hatch. All this attention is great and helps keep the Type R planted on the pavement, but it doesn't seem like there was enough focus on airflow to the front cooling stack, hence the cooling issues.

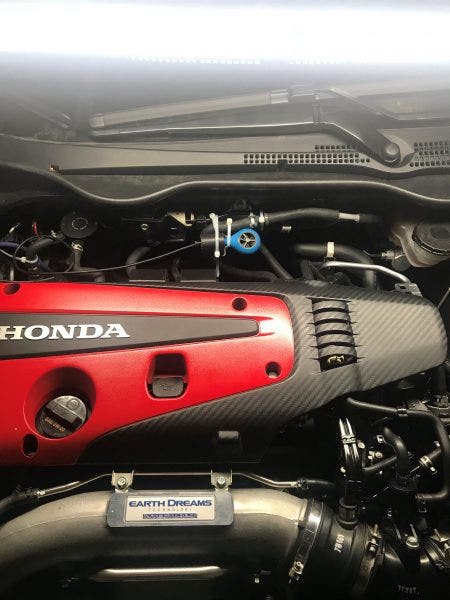

Our engineers chose to take advantage of Honda's aero kit to help with lowering the temps in the simmering engine bay. We've already occupied the driver's side brake duct with one 19-row cooler for the engine oil, so our attention turned to the hood scoop.

Examining what's under the hood scoop, we noticed Honda has already installed some permanent channels to direct airflow out through the fenders. There is still a channel for the air to flow straight down behind the engine, acting as a combination of downforce and expelled engine bay heat.

Reinforcements Have Arrived

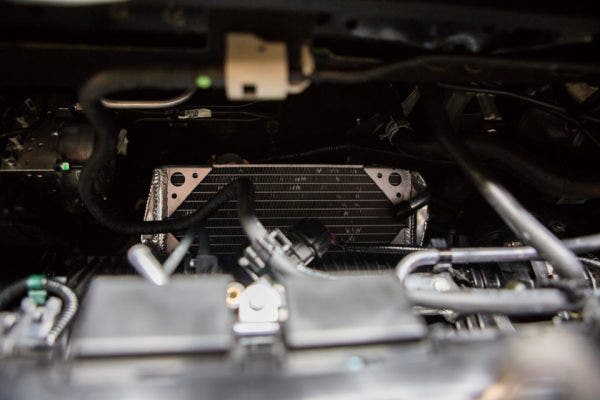

With the steady airflow slipping behind the large void at the back of the K20C1, under the scoop was the perfect location to affix a secondary radiator. Utilizing one of our smaller radiator designs, our engineer did just that, tapping into the coolant stream right after the Civic's heater core. Even this small addition to the cooling system can drop the temperature enough to give the FK8 more of a fighting chance against the heat.

The CTR itself wasn't the only thing that needed a little help for this project. Since this cooler relies heavily on real-world wind forces being funneled into the hood scoop, devising a reliable dyno testing method proved to be challenging. Unlike the testing for our oil cooler, where we were able to bring the track to us, we sent our Secondary Race Radiator Kit to United Speed Racing (USR), based out of Georgia.

With our secondary radiator equipped, Jason from USR was able to give us real-world feedback throughout the various Global Time Attack events his team competed in throughout the year. Though it's tough to get clinical back-to-back tests while also competing on the track, he was able to run our setup in a few different configurations, stating that "every little improvement adds up to a bigger result." Jason also went on to say that the difference might not be night and day, but there is definitely a positive result after installing the additional radiator. Even with thrashing the USR CTR around the track in the humid southern heat, or in the desert on Buttonwillow, the auxiliary cooling solution kept the notoriously hot FK8 on the track longer.

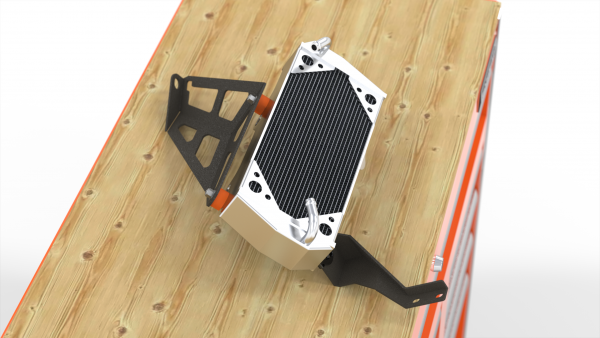

Honda put their heart and soul into the FK8 to make this Civic a true track slayer, but even still, it needed some help to contend with the heat. With the Secondary Race Radiator equipped, USR showed us that even this smaller radiator design is enough to give the Civic Type R the backup it needs to stay on the track. Given the specialized use case for these kits, we made the executive decision to have our master fabricator, Mike, produce a batch of brackets to secure the radiator in place. Keep scrolling for a look at the production and the full behind-the-scenes video on the development of our performance cooling solutions.

Thanks for Reading!

-Nick