As is Tradition - Direct Fit Catch Can R&D

Tradition is something that spills over into just about everything. For the most part, we as a species like to settle into a groove. We keep things the way they are because that's just how they've always been done. While change is sometimes a good thing, it's often nice to have that hint of familiarity in the air. Not to mention, putting your foot down and standing by your principles holds a certain kind of respect.

The muscle car scene is deeply rooted in tradition, especially when it comes to Mopars. While the new Chargers and Challengers might be trending towards a sleeker and sexier outward appearance, what's under the hood is reminiscent of another time. Calling out the size by cubic inches rather than liters, and even just the different editions bring plenty back to the heyday of the muscle car.

We made sure to arrange visits from just about every iteration of the modern Mopar.

Once you get behind the wheel of a Mopar, it's clear to see why we want it to stay the same. With the baby 5.7L V8 starting off at 370 horsepower and just shy of 400 lb-ft of torque, the Charger and Challenger have the power to move you back in time, and the power and size only go up from there. It's no wonder that Mopars are starting to dominate the roads; they're thumping V8s combined with sprinklings of modern flair.

There's another tradition within the muscle car lifestyle, one that doesn't spark a happy nostalgia: blow-by. There are unfortunate side-effects to the explosive power of those monstrous V8s. The huge pistons need a big bang to shove them to the bottom of the block and generate all that power. The problem is that some of that energy slips past the piston rings and into the crankcase, causing unwanted pressure.

In the good ol' days, we were allowed to vent that pressure right out of the block, but the O-Zone wasn't exactly pleased with that. In order to appease the force of nature that was literally saving our skin, manufacturers began to re-route that crankcase pressure back through the intake system. While it was a step toward soothing global warming, those repurposed crankcase gasses carry stowaways in the form of unburnt fuel vapors and droplets of oil. Theoretically, these should just burn up as they recycle back into the combustion chamber, but that's not always the case. These droplets can stick to and gum up just about everything in the intake tract. The intake manifold, valves, and forced induction components can all fall victim to blow-by.

Don't worry though, because we have already been hard at work developing a catch can system to keep the innards of your Mopar safe from itself. The idea of the catch can is simple. Using the internal baffle on our compact catch can design, we place the can so that it intercepts the contaminated crankcase gases. Inside the can, the oil and fuel vapor condenses and collects. What returns to the intake is nothing but clean air. Since Chrysler was nice enough to make the PCV system easily accessible, designing the lines would be a cinch. The challenge(r) came from deciding where to mount our catch can.

Our engineer, Dan, inspects the engine bay of our 2015 Charger R/T loaner for the best place to mount our catch can.

In the past, muscle cars were notorious for having an excess of space under the hood. Even with the monstrous V8s wedged between the front wheels, it was almost as if you could climb into the engine bay to do any sort of wrenching. Knowing this, we figured there would be ample space for one of our catch cans. However, this is one tradition that's changed on the modern Mopar. Upon raising the hood on our loaner cars, we found that designing a mounting bracket was going to require a little more finesse.

We were originally looking at the strut tower as the ideal mounting location. It made for a sturdy base, but the popularity of strut tower bars thwarted our plans.

Our engineer's first inclination was to use the strut tower as a mounting base, leaving plenty of space for servicing the can and a clear route to the PCV system on the V8 models. The problem was that our kit would pose the ultimatum between protecting your engine or adding rigidity with a strut tower bar. We wanted there to be the option for both, so Dan found some common ground with a new bracket.

Using this bracket setup, we are able to mount the catch can to the vehicle's radiator support, not only giving plenty of space for emptying the collected blow-by from your 345 or 392's PCV system, but also making our lines even more straight-forward.

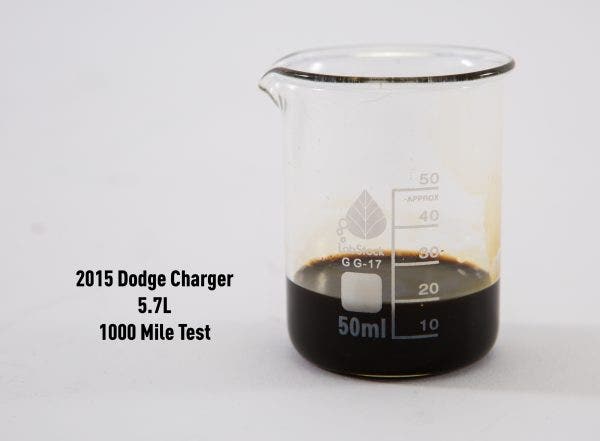

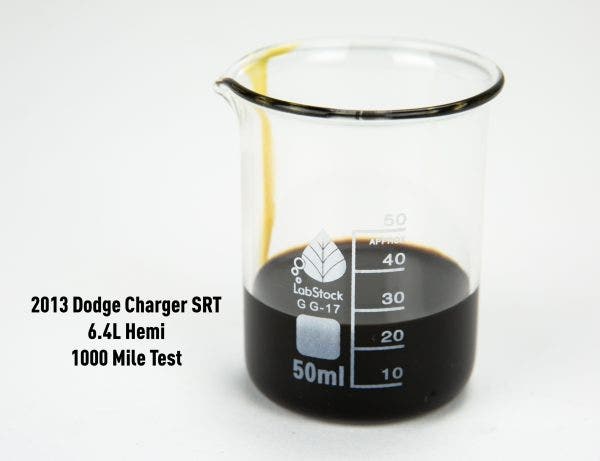

Speaking of collecting blow-by, it's not all about the outward appearance of our catch can system, but rather what we find on the inside. Designing and test fitting our kit is only half the process, and we have to make sure it all works. To do so, we sent both our 2015 Charger R/T and our 2013 Charger SRT out for our standard 1000-mile test cycle. This test gives us a clear indication of just how much our system will collect, and will give us a gauge on how often it will need to be emptied.

Depending on the size of your V8 Mopar, between 20-25ml of oil is slipping through the cracks and creating the building blocks for carbon buildup on the intake components. We conducted our testing in the warmth of the summer, so come colder weather, we should expect to see an increase in the amount of murky stuff.

“If it ain't broke, don't fix it” is the motto that goes along with keeping steady in your ways. The power delivery under the hood of modern Mopars surely isn't broken and has kept with the tradition of pushing you back in your seat once the light turns green. Keeping the valves in your Hemi clean is something we hope to become something of a tradition as well.

Thanks for Reading!

-Nick