We are always trying out new testing methods and conducting really different kinds of R&D here at Mishimoto. A few weeks back, we performed quite a cool test to evaluate heat transfer on one of our upcoming intercoolers.

What we did!

We have been seeking ways to evaluate the transfer of heat through intercooler cores that we design. Although we have a variety of software programs that can reveal air dispersion and flow, additional data points are always helpful, especially if we can see the changes as they occur.

At some point we stumbled across thermochromic paint additives. This interesting powder has been around for quite some time. It is simply added to a paint clear coat, and it tints the clear to your color choice, in our case, black. Then, once the painted object reaches 86°F, the tint becomes translucent, revealing the base color.

Now, if you are like me, you are already online looking for this paint additive and making plans to paint anything and everything with it. Can you paint an entire car with this? Yes, you can. Is it really awesome? It very certainly is.

Below is our Mustang intercooler prototype!

Mishimoto 2015 Mustang EcoBoost Silver Intercooler

Once we had our clear coat mixed with a black tint, it was sprayed onto our silver 2015 Mustang EcoBoost intercooler.

Painted Mishimoto 2015 Mustang EcoBoost Intercooler

Once dry, this paint produced a flat finish.

Painted Mishimoto 2015 Mustang EcoBoost Intercooler

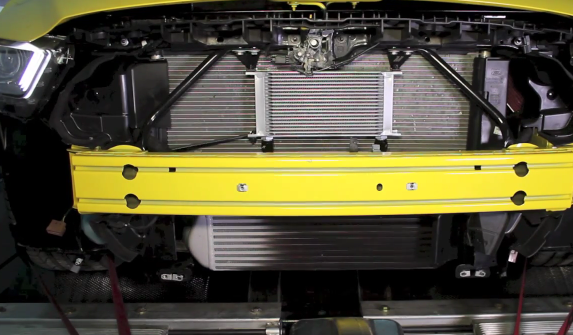

The cooler was reinstalled on our Mustang for the final test!

Painted Mishimoto 2015 Mustang EcoBoost Intercooler installed

Why does this help our testing process?

Part of the reasoning behind performing this test is its general awesomeness. More importantly, we wanted to see the visual impact of heat on our prototype intercooler. We could display how the transfer of heat occurs and how quickly heat dissipates from the core. The activation temperature was perfect for our cooler. Our initial tests (using standard thermocouple sensors) showed that inlet temperatures reached over 220°F while our outlet temperatures stayed within a few degrees of ambient temperature. Instead of just looking at readings on charts and sensor output, we could watch physical changes to the core in real time and see the impact of temperature fluctuations on our intercooler.

Core dispersion of airflow/heat was another interesting data point. Some of our intercoolers are quite tall, so pushing airflow to the full height can be a challenge. In the past we have used internal air diverters cast into the end tanks to force airflow through the entire core to achieve maximum heat transfer. Once complete, we would normally use CFD (computation fluid dynamics) software to evaluate airflow. We will still use this software during product design; however, the thermochromic paint allows us to watch as heat moves through each bar on the intercooler, emphasizing which areas are getting hotter than others.

In short, although this test was fun, it also gives us valuable information for our product design as well as more testing data!

The video!

Enough talk! Check out the awesome results from this test!

Thanks for reading!

-John