Motor Cameo - Baffled Oil Catch Can R&D, Part 1 - Stock Review and Design Plans

It's happened to all of us at least once. You're rewatching one of your favorite cinematic adventures from years ago when you spot an actor that is now a mega-star, but in a much younger state, performing in one of their break out roles, or even just making a cameo. While this performance might not match this actor's current performance level, or could even be cringy at times, it's what gave them their shot at making it big. The same could be said about the Nissan 350Zs sporting the VQ35HR. While its performance never falls under the "cringy" category, the DE's replacement only made a brief cameo in the Z cars before moving on to bigger and better things. Even though the HR is uncommon in the 350, it still requires the same, if not more protection from blow-by as the DE, which is why we here at Mishimoto are already hard at work on a full catch can kit.

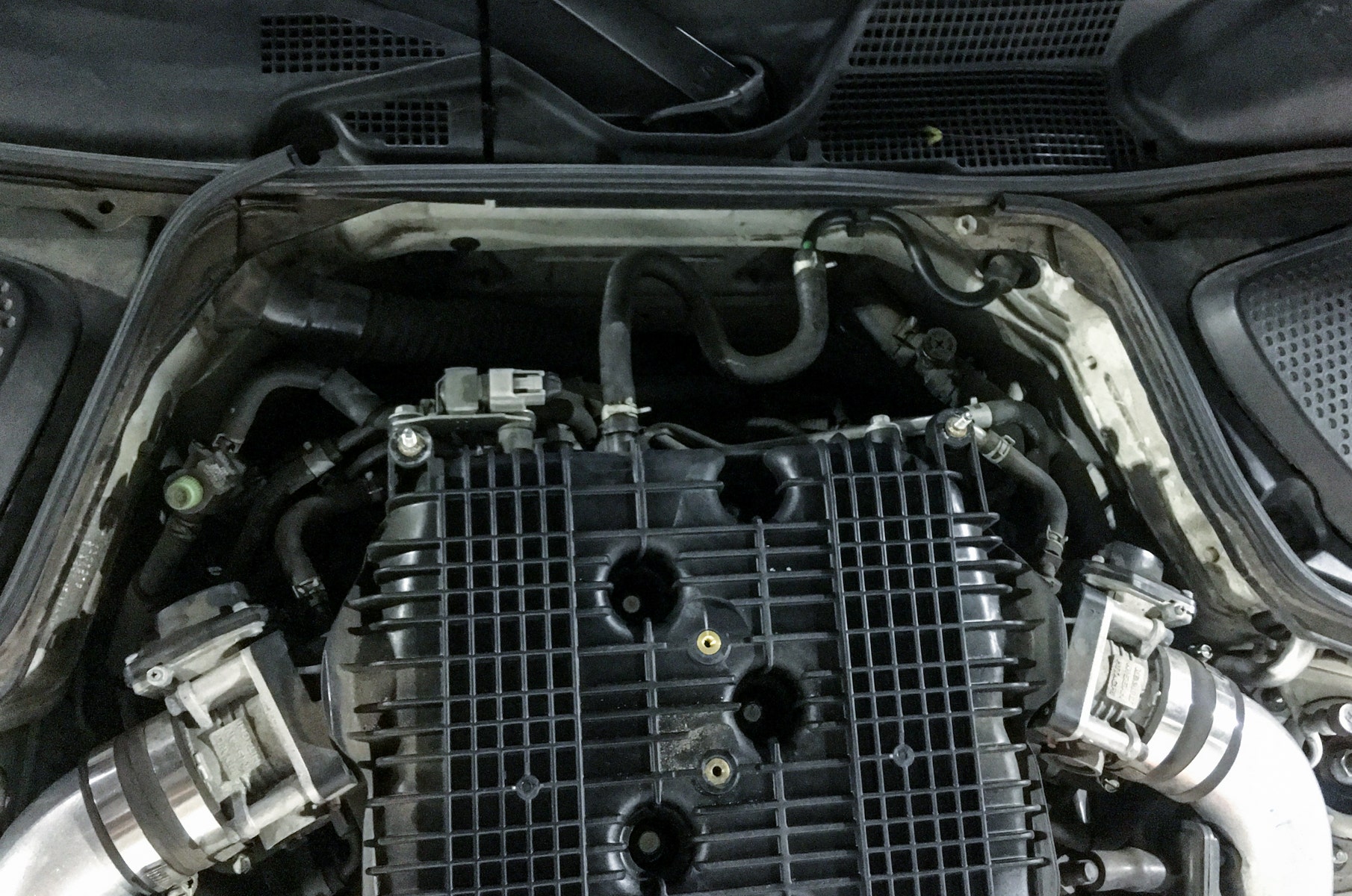

The VQ35HR might have been late to the 350Z, arriving under the hood in 2007, but it ended up laying the foundation for the 370Z from 2009 through the next decade. The most evident difference between the HR engine (for "high revolution") and the DE variant is the addition of a dual-runner intake plenum to help the V6 breathe deeper. Other updates are not immediately visible when you open the hood but are more responsible for taking this VQ to another level.

The updates didn't stop with the dual intake runners. Direct injection is still about 2 years off in the Z car, but Nissan gave the VQ a slight bump in the compression ratio to squeeze out a few more ponies. Even with fuel regularly washing over the intake valves, engine oil blow-by and carbon buildup are already concerns regarding the VQ35, and now even more so with an increase in compression. For the 350Z to continue its peak performance, the intake valves need to stay clean.

Luckily, we've been working on a catch can for the HR, so our engineer, Dan, got right down to business with our donor vehicle.

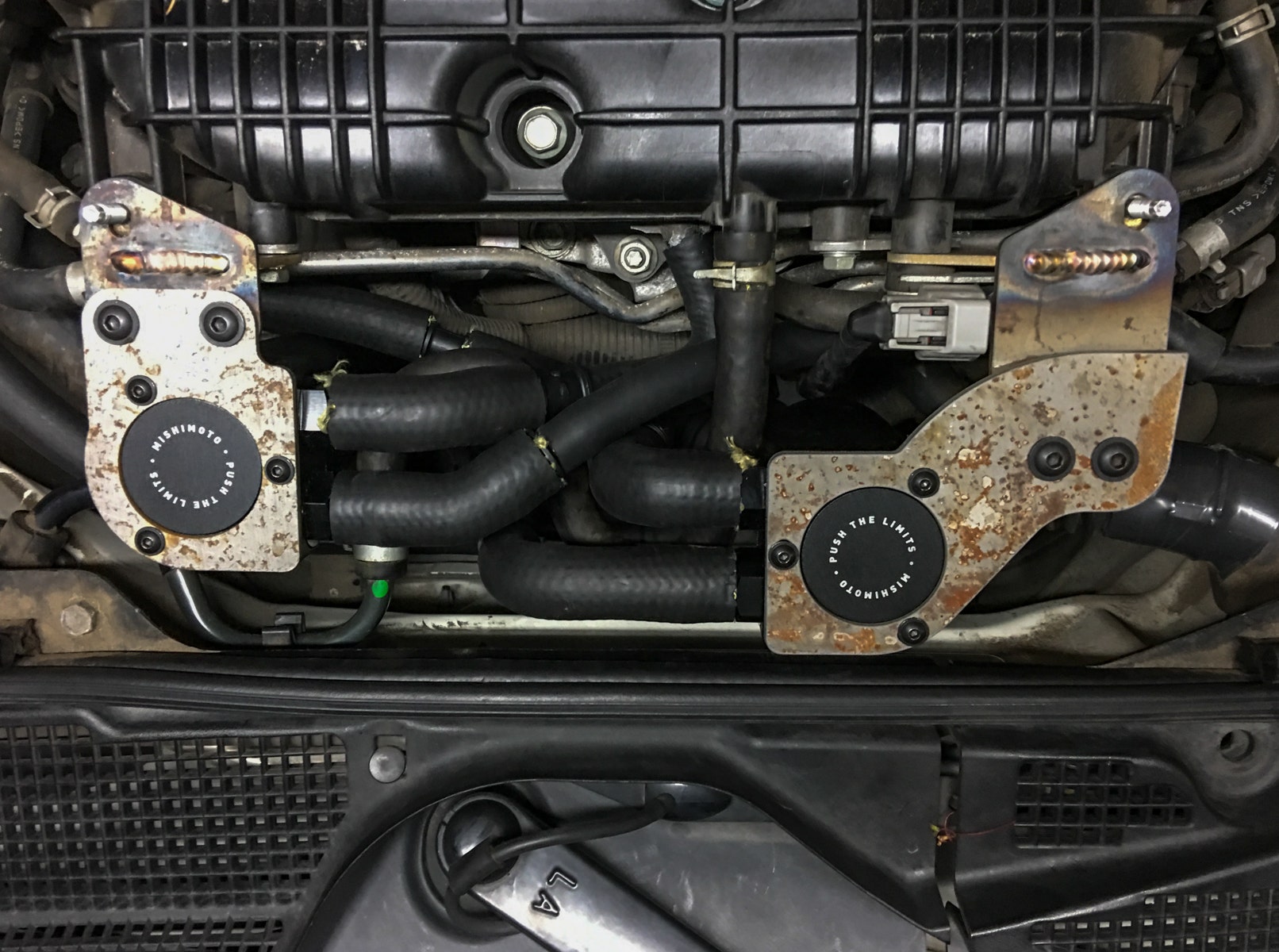

Available space is half of the challenge when it comes to integrating a catch can kit under the hood of a 350Z. True, there is a nice open spot on the front side of the engine to mount a pair of cans similar to our 370Z kit; however, the ports that we would need to access are located on the rear of the HR's new intake plenum. So, to avoid using a mile of hose on our new kit, Dan located a new spot on the rear of the engine to mount these cans in closer proximity to the PCV ports.

With the new mounting location determined, Dan had three things to keep in mind for the rest of the design. The fitment needed to be clean, which means no absurd lengths of hosing. The brackets needed to be sturdy, and they needed to mount in such a way so that servicing these cans doesn't require a master mechanic.

There's only so much control we can have over the lines. We can do our best to ensure a clean and organized routing, but generally speaking, the lines will end up routing around other systems in the vehicle. One option for us, though, is adjusting the angle of the catch cans' ports. Using this mounting location, using our standard compact catch can mean angling the in and out ports of the cans directly toward the engine or the firewall. Instead, Dan opted to utilize our parallel-port compact catch can lid, allowing for a more manageable line routing. He also arranged the cans for a clean crossover effect that reduces the installation difficulty and lessens risking kinks or bends in the lines.

To make a sturdy yet serviceable bracket, we split our design into two pieces. One side of the bracket mounts to the engine head, while the other attaches to the main bracket. This slick design ensures that both cans stay firmly attached, no matter how much the engine vibrates. It also takes the headache out of draining any collected blow-by. Instead of squeezing your hand underneath, and loosening the bottom 0.3 mm of a turn at a time, our bracket will detach with a single bolt, allowing you to pull the can up to get your whole hand on it.

With the prototype complete, it's time to see just how well our kit protects the VQ35HR. So, we sent our donor 350Z on our standard 1000 mile test. This test first ensures there are no significant changes to the PCV pressure that would trigger a very unwelcome check engine light, but also acts as a gauge of how much blow-by we can expect to see in the cans. While waiting for the return of the 350Z, Dan is steadily working on a more refined look for our catch can kit to ensure a clean aesthetic under the hood. Make sure that you stay tuned for the first look at our production sample kit and our testing results.

Thanks for Reading!

-Nick