Heavy Breathing - 2017+ Honda Civic Type R Performance Intake R&D, Part 3 - Production Sample and Test Results

At some point early on in our car obsessed years, we've all dropped in a cone filter, with a shiny tube, possibly with some flimsy heat shielding and called it an intake. We've also claimed we could feel the unharnessed power now bellowing out from under the hood. We've all been guilty of it. Really, it was just louder, and maybe with the right combination a few extra horses were added to the pack. Here at Mishimoto, we've moved way past that, as you can see from the amount of fabrication going into developing our initial intake prototype, not to mention the sheer amount of testing that has lead us to our first production sample.

Opinions of the latest generation CTR's styling can be quite polarizing. While the massive rear wing and aggressive looking body kit aren't for everyone, Honda has made sure that it's all installed in the name of aerodynamics.

Much like the FK8, function over form is the direction that we headed in with the development of this kit. Even though the CTR has some obvious styling cues to give it that more aggressive look, the gaping grilles and towering spoilers all serve a purpose to help guide the Civic around the bends as accurately as possible. With that mantra in mind, as well as the general feedback from our customers on the baffled catch can kit, sticking with the OEM+ theme was our path forward.

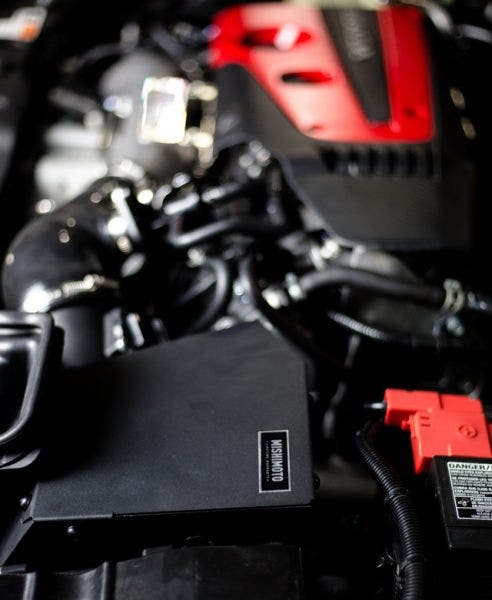

Black matches everything. Even with the conspicuously red engine cover demanding your attention every time you pop the hood, our blacked out intake kit fits right in. The lack of vivid colors to the kit might not accentuate the improvements our design has made over the stock system, they are still immediately noticeable.

Our more durable silicone combined with the larger box and new MAF housing add the subtle hint of performance to the CTR's engine bay. Our final production unit is going to have a few differences in appearance, including all black hose clamps and a slight change to the MAF housing's external design.

The visual improvements might be subtle, but since it's the first component to greet you as you open the hood, you begin to pick up on the improvements right away. Much like Honda's quest to functionalize their aggressive styling, there is a reason behind our improvements. First, our box is larger. We've increased the size and shape of our box in order to fit our better flowing air filter. We have also separated the MAF housing from the airbox so we could increase the inner diameter and allow more air to pass through. Finally, and probably the most noticeable, is we've changed the intake boot, and replaced it with 5 layers of sturdy silicone. The larger diameter and smooth interior will allow the fresh air to pass through and into the turbo with much less resistance.

Our newly designed hose is also pulling triple duty. In addition to offering a slick surface for the fresh air to pass through with ease, the heat resistant fibers imbedded into the hose helps with isolating the engine bay heat from the MAF sensor. With the position of the air intake in regard to the sweltering turbocharger, it's important to ward off as much residual heat as possible. Also, our intake boot acts as a flexible coupler between the engine and the securely fastened airbox, which helps with how the K20C1 rocks around in the engine bay, especially if you have a lead foot.

There's much more to redesigning a vehicle's intake system than adding a cone filter and silicone hose. Granted, those items help improve on the turbo's ability to suck more fresh air into the system, but there's much more you don't see that goes into the development. For this intake kit, we spent plenty of time testing on several platforms to ensure its performance

Benchwarmer

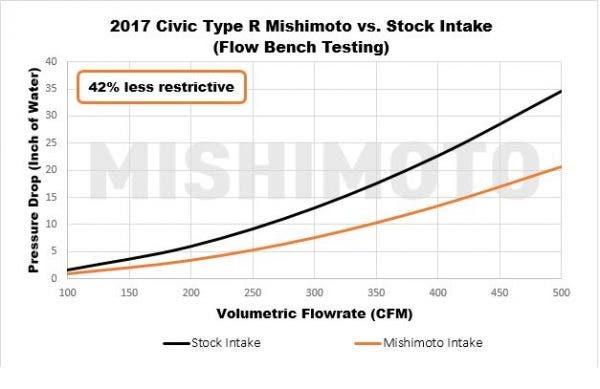

The first step in the development process is to devise a plan to increase the flow. The answer might seem obvious given the design of the stock system. Typically the plan would be to ditch the airbox and accordion-style hose in favor of a wider hose and more free flowing filter. In this case, that's partially correct. Looking back at our last post, the plan was to keep the box, but our initial prototype spent some time on our flow bench to determine just how much larger and sleeker our hose could be.

Ye logs every detail of our preliminary prototype's flow characteristics. Nailing down the proper flow in the hose is step one in improving on the stock unit's design.

Since this hose covers a short distance, and incorporates other systems, we couldn't just use the largest piece of silicone we had available to span the gap between the MAF housing and the aluminum intake runner. Our improved design still had to follow a specific path. Even under these restrictions, our engineer opened up the flow of fresh air into the turbo. By removing the jagged flex pipe, and other sources of turbulence, we were able to improve the flow by 42% with our full intake kit.

Trimming the Road

The MAF housing must be perfect, and not because we just really like our MAF housings, although, the sleek black anodizing does look great under the hood. It's more of the fact that in most intake systems, the MAF sensor holds a majority control over whether you'll get the dreaded amber light on your dash. This is where our road testing comes into play.

The MAF sensor in your FK8 communicates the amount of airflow passing through the housing to help the ECU determine just how much fuel needs to be mixed in the cylinder to run at peak efficiency, also known as your fuel trims. The short-term fuel trims are the ECU's immediate response to the airflow data supplied. The long term fuel trim, or LTFT, is the overall trend of trim adjustments that the ECU is performing, typically measured in a positive or negative percentage. Just by reading this data point, you can tell whether the vehicle is running too rich or too lean. If that percentage creeps over a certain threshold, it triggers the check engine light.

As previously discussed, this sensor poses the highest risk to derailing an intake project. Ensuring that the new MAF housing satisfies the demand of the sensor is key.

Since the idea behind a performance intake is to open up the entire system to allow more air in, the LTFT becomes a major hurdle during the development, especially when the plan is to make power on the stock tuning. The stock sized MAF housing becomes a restriction once we start beefing up the rest of the system. Naturally, we would want to increase the size of the new housing along with the hose and the more free-flowing filter. However, the MAF sensor is specifically calibrated for its housing, and the LTFT will begin to rise with the increase in size. Knowing this, we had to tread lightly when designing our new MAF housing, but with some precision adjustments we were able to come up with a new design that allowed more air in, but kept the fuel trims in check.

Our final production MAF housing will have some minor changes to the exterior design.

Before we can test to see how much power the complete kit will add to the already speedy Civic, we needed to be sure that we kept the check engine light at bay. We ran a series of road tests, which involved driving at least 1000 miles on various MAF housing sizes, letting the ECU “learn” new LTFTs for each. Even with our housing adjustments, we were still within the realm of safe operation, and with over 6000 miles logged for road testing, we were ready to see just how much power this intake adds to the Type R.

Stationary Bike

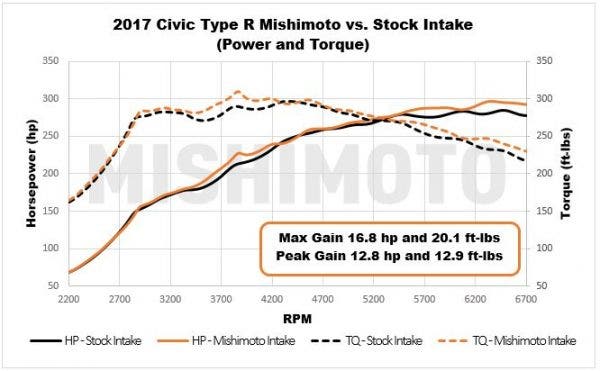

It might seem like we took the long road to finally getting on the dyno, that's just across the shop floor, but there's a good reason. We need to make sure that we have all of our ducks in a row before we test just how much power our intake kit produces, since accuracy is key. It's important that we complete the road testing before hitting the dyno so that the LTFT has settled into its normal operation range and we don't skew the results. With all of the preliminary testing complete, our CTR made its way to the dynapacks.

Now for the moment you've all been waiting for, the power figures. With the final iteration of our intake kit, we made several runs on our Dynapack system, to compare the stock equipment and also ensure the accuracy of our results. With our testing complete, we produced max gains of 16.8 HP and 20.1 TQ, with a 12.8 HP and 12.9 TQ peak gain on the stock tune, and the potential to increase once tuners begin to crack the complex FK8 ECU.

Track Fiend

There is no doubt that plenty of this generation's Type R's will see the track, and with the amount of time we've been spending at Raceway Park in Englishtown, NJ with the Focus RS, we felt that Type R #01254 could benefit from some track time. It's one thing to perform bench line testing on dyno, but we sought to get a true feel for our Civic Type R, so our in-house Stig suited up and pushed it to the limits around the road course.

Dan and Ye work on calibrating the data logging software before hitting the track in Englishtown.

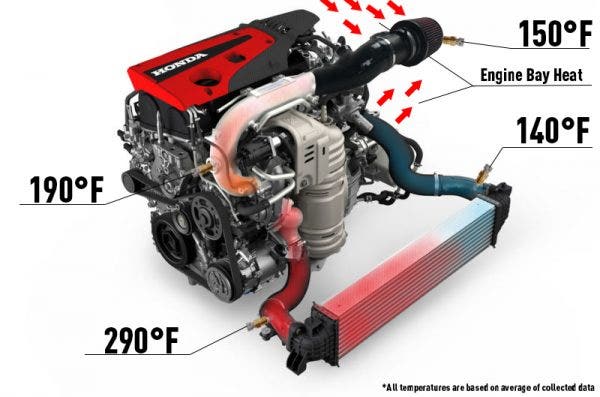

One of our secondary objectives throughout the day was to test the air intake temperatures in a real-world setting. Also, with the popularity of cold-air, and box-less intake systems, we wanted to compare our system to the systems that are historically popular in the world of Honda. For this test, we installed an excess of sensors throughout the different systems of the K20C1, and relayed them back to our AEM AQ1 data logging system to collect the results. With all systems go, we set out for three sets of 5 laps around the track.

The highlighted course was originally selected to be the ideal torture chamber for our Focus RS's differentials, but it also proves to be a perfect proving ground for our Type R. Eric can round the course in just under a minute all while putting every system to the test, as he demonstrates in the following video.

We already knew before hitting the track that keeping the box was beneficial. Keeping a sealed, and dedicated channel of air directly to the filter only helps to ensure an improved flow throughout the full system, not to mention the added heat protection.

With the box attached the fresh air is able to stay cooler before entering the turbo. The importance of keeping the air cool at the intake becomes apparent once we read the temperature at the intercooler inlet. While still higher than we would want, the stock unit can still keep up with cooling for the most part.

With our box removed, we did find that it gave the CTR a much more pleasing sound once Eric put the hammer down, however, there was no protection from the residual engine bay heat. Without the box, the intake temperatures spiked to an additional 40°F at points. This increase in temperature doesn't just rob the Civic of performance, it also puts additional strain on the intercooling system and cooling system. Chalk one up for keeping the box.

You might notice that the intake temperature at the filter remained the same for the box-less test. Since it was mounted in the same location, we were getting the same readings from this particular sensor, but couldn't measure the residual engine bay temperatures. However, the rest of our sensor array was able to record how the additional heat at the filter affected the system.

Form and function. It's a topic often debated in the automotive world, especially when it comes to aftermarket components. Some might argue that the FK8 is more form than function, however throughout all of the testing we've performed over the last few months, we can attest that it's definitely a combination of the two. When it came to our intake, we wanted to make sure that it was more function than form. With plenty of dyno runs, road testing miles, and track time under our prototype's belt, we feel that we met our goal.

Thanks for Reading!

-Nick