Improved Induction - Silicone Induction Hose R&D, Part 1: Stock Review

Many would question the motives behind someone who purchases a four-cylinder turbo of what has come to be a staple of the American muscle culture. Personally, I get it. I'm one for combining performance without having to sacrifice fuel economy or aggressive styling. On top of that, turbo engines open a whole new world for modification, and one of the first steps for most is to increase the airflow to the turbo. The engineers at Chevy had to make a trade-off, however, when it came to designing the stock induction hose for the 2.0T Camaro. I'm sure they would prefer designing each aspect of the Camaro to milk every single drop of horsepower out of this newer, and smaller engine, but they also have the noise, harshness, and vibration tests to contend with, which induction sounds fall under. So, in short, they had to trade performance for cost, and comfort, when designing the stock induction hose.

An overhead view of the stock 2.0T induction hose.

We here at Mishimoto understand that it wasn't exactly the objective of Chevy's engineers to design a sexy, high performance induction hose, and as previously stated, they had that pesky obstacle of the NHV tests to overcome. Sexy hose production falls to us, then. Much like our 2016 Camaro SS, the stock induction hose on the 2.0T really takes away from the initial "Wow" factor one would usually get from popping the hood on a Camaro. The stock induction hose is an eye sore, and is accentuated by the now extra space in the engine bay where the other two to four cylinders would typically reside. Our engineers are already working on a new design that will spruce up the bay, and return that "Wow" factor (in three different colors), but will also improve on the initial design and put a few more horses under the hood.

The first half of the stock hose is constructed from the standard polyurethane that's found under the hood of most modern cars. Most manufacturers stick to this similar design for their induction hoses since it's fairly cost effective, and generally durable, however bland it may be. The ribbing on the exterior of the hosing allows Chevy to produce an overall thinner walled hose, which will save on weight, and maintain its overall strength. The downside of using this specific construction is that over time the rubber section will wear out. Granted, the life of rubber hoses under the hood depends on the care of the hose and engine itself, but with the constant cycle of heating and cooling, and the effect of saving on cost, the hose could start to show signs of wear in as early as 5 years. Our plan is to craft the induction hose from silicone, creating not only a more durable part, but also a more free-flowing one.

The stock airbox and hose.

Creating an easier path for the air to follow is one of the main objectives for the new induction hose, an issue that starts to present itself as we move closer to the turbo. The idea behind this design is for longevity of the part. The stock flex fitting allows the hose some give, and the ability to move around to compensate for engine vibration, or bumps in the road. Basically, Chevy wanted to make sure the car wouldn't shake itself apart while you're driving to work in the morning. The drawback to this design is that, on top of closing the diameter of the hose, it also creates turbulence in the airflow and slight differences in pressure. This is not necessarily a huge problem to have, but our engineers would like to straighten that out.

The junction between the hosing and the turbo muffler. The irregular shape of this junction causes unwanted turbulence and pressure drop.

Speaking of straightening things out, the next issue that arises with the stock hose is the turbo muffler. Remember those noise, harshness, and vibration tests? This is what comes out of it. The idea behind intake silencers is to dampen the harshest sounds of the engine through the rev range by way of adjusting the sound waves. The silencer on our Chevy has two main components to facilitate the dampening. First, there is the chamber, which gives the sound waves a space to reverberate and expand in. The hard plastic exterior allows the wave to bounce around until there is a larger peak between the waves. The other piece is the baffling which is placed inside of the chamber. The array of holes allow the high frequency sound waves to escape in to the chamber to reverberate and expand, and the fins make decrease the area in which the waves are now colliding with each other and to speed up the dampening. The silencer isn't necessarily strangling the engine for air, but it also isn't doing any favors. It's another variation in the shape of the hose, and extra air turbulence. Worst of all, it just about negates one of the perks of buying the turbo model: the whine.

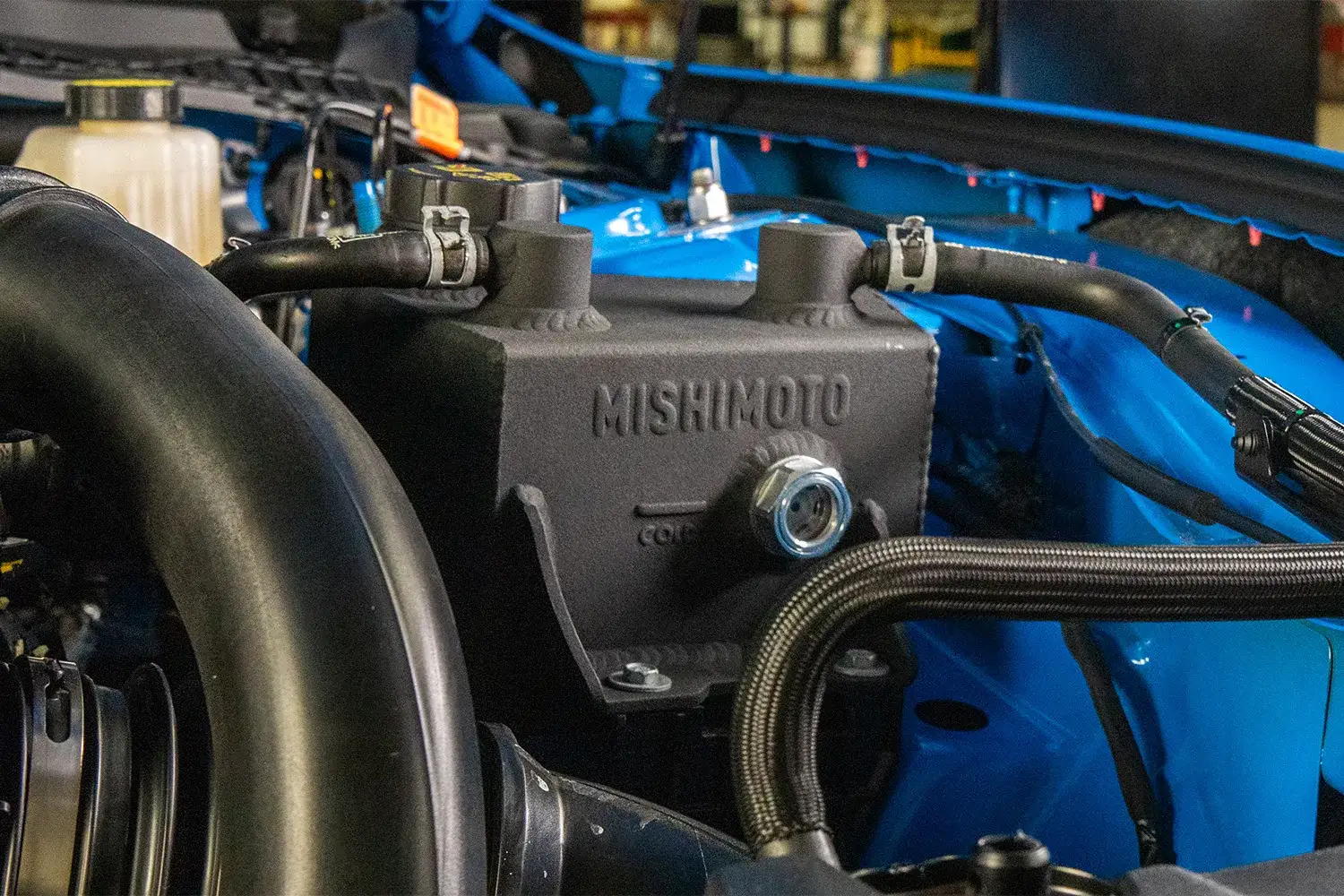

A look at the turbo muffler in the engine bay.

An inside look at the turbo muffler. The baffling and fins change the pressure of the air, in turn creating different sound wavelengths to cancel out the high pitched whine of the turbo.

Our engineers have already been hard at work on increasing the airflow from your Camaro's stock airbox into the turbo. Our plan starts with putting the silencer on the chopping block, to let you hear that turbo spool up. We're also making the overall diameter hose wider than stock and forming the entire hose as one piece. These changes will allow for not only an increase in the volume of air, but also a more uniform flow from the airbox to the turbo, resulting in a boost in power.

Here's a sneak peek at our current prototype. There was a slight hiccup with the fitment, and it bumps into the fan shroud, but we can get it on for initial testing. We just want to make sure the final product has the best fit and performance possible, so we have another prototype on the way.

The final version of our prototype is due back in the next few weeks for a final fitting and testing. Stay tuned.

Thanks for reading!

-Nick