Unleashing The EcoBoost - Downpipe Development, Part 1: Stock Component

Interested in purchasing our Mustang EcoBoost Downpipe? Check out more details on our product page linked below!

Mishimoto Ford Mustang EcoBoost Downpipe!

Opening up the exhaust on a turbocharged vehicle is a great first modification that can make a big impact on drivability, vehicle sound, and driver enjoyment. Typically, a vehicle will see improvements in horsepower and massive gains in torque output. Emissions and sound requirements normally restrict the size and efficiency of stock exhaust systems, which explains why big gains result from enlarging the piping and eliminating or reducing restrictions within the piping.

For this project, we will focus our efforts on designing and testing a new downpipe option for the 2015+ Ford EcoBoost Mustang. Before tackling our downpipe design, we will take a look at the stock unit pulled from our Triple Yellow shop vehicle.

Stock Downpipe Features

If you haven't peeked under your new Mustang, this portion of the article will give you a look at what the stock vehicle is equipped with in terms of the downpipe.

Stock 2015 EcoBoost downpipe

The downpipe mates the turbocharger to the rest of the exhaust system. This component runs from the passenger side of the engine bay down under the vehicle and connects with the rear portion of the exhaust right behind the transmission.

Stock 2015 EcoBoost downpipe

Stock 2015 EcoBoost downpipe

The stock downpipe is rather easy to access and remove; six bolts and some shimmying, and the pipe is out. It is almost as if Ford designed this component with the implication that it would be tossed to the side for a larger unit.

Once out, we can get a closer look at the individual components.

Stock 2015 EcoBoost downpipe removed

Stock 2015 EcoBoost downpipe removed

Now, let's go through each component/feature of this pipe.

Turbocharger Flange

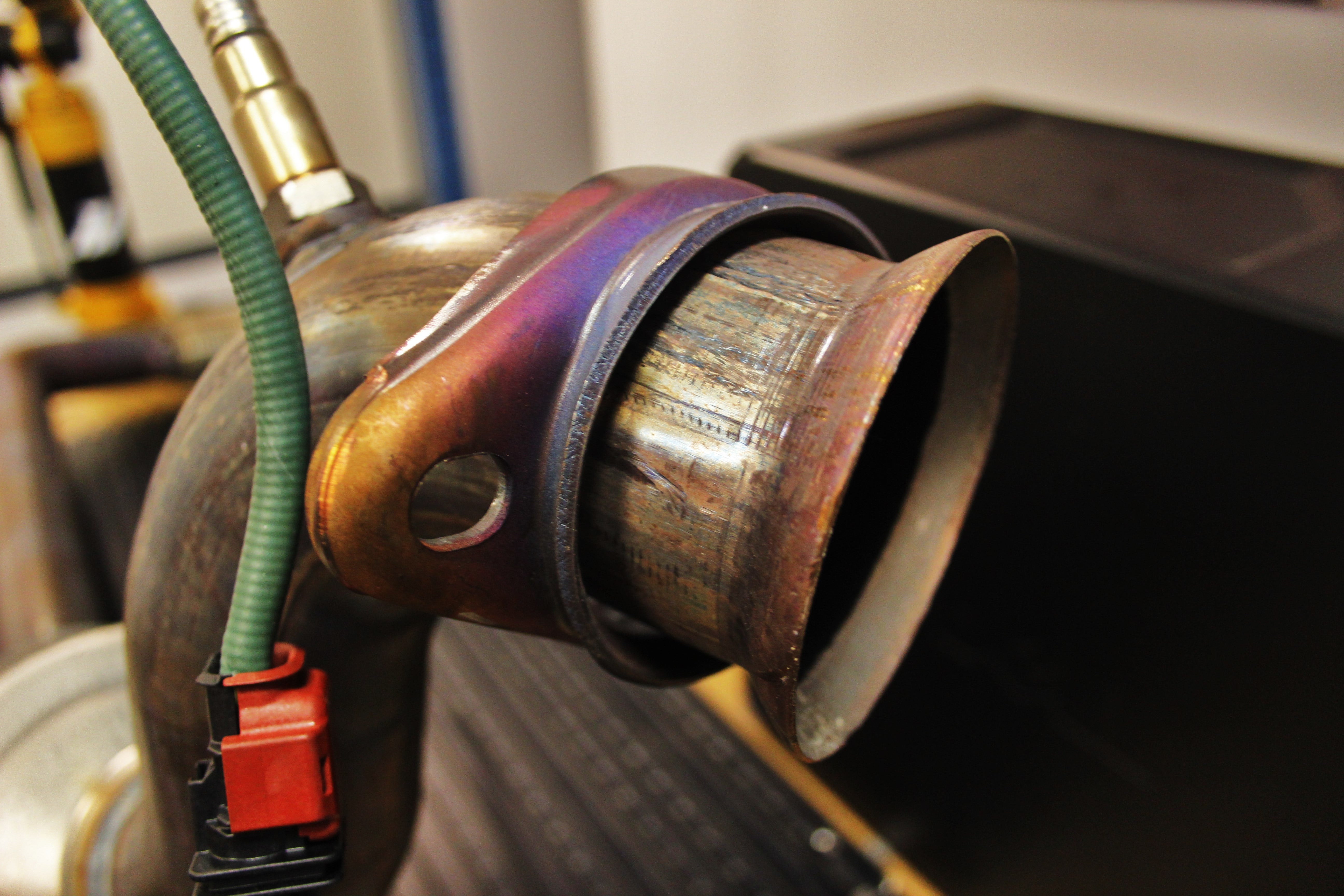

Stock downpipe turbocharger flange

The stock turbocharger flange is a pretty unique setup. The Mustang utilizes a two-bolt, ball-style flange. Typically with modern downpipes, we see a multiple bolt (four to five) flat flange that mounts to the turbocharger exhaust housing.

Check out a side-view profile of this connection.

Stock downpipe turbocharger flange

The inner diameter of the pipe measures 2.75" from this flange until it meets with the catalytic converter. After the converter the piping measures 2.5" up to the flex joint. Following the flex joint, the pipe tapers to 2.25" to mate with the rear portion of the exhaust. We should have no problem increasing the size of this with the allotted space on this vehicle.

Stock downpipe turbocharger flange diameter

Oxygen Sensors and Catalytic Converter

As with most modern four-cylinder engines, the EcoBoost features two oxygen sensors that are both plumbed into the downpipe.

First oxygen sensor

The second oxygen sensor is positioned within the catalytic converter assembly.

Second oxygen sensor

Flex Joint

The flex joint is toward the rear of the downpipe. This component allows the pipe to flex, which reduces the chances of cracking or damage from engine movement during acceleration. As with the flanges, this flex assembly is fairly unique compared to what we normally see on exhaust systems.

Stock downpipe flex joint

Rear Exhaust Connection

The last portion is the rear connection point, where the downpipe attaches to the rest of the exhaust system. We typically see a flanged connection here; on the Mustang, however, we have a pretty slick slip-joint.

Stock downpipe slip-joint

Data Collection

Now that we had an idea of what we were getting ourselves into from a development standpoint, we needed to collect dimensional information from the stock pipe so we could begin working on our design. We placed the stock pipe on the Coordinate Measuring Machine (CMM) table and set our engineering team to work.

Stock downpipe on CMM table

Stock downpipe on CMM table

Stock downpipe on CMM table

On The Horizon

We have big plans for this downpipe. Check back with us next time for a look at our 3D renderings and an explanation of our design and features.

Thanks for reading!

-John