Mishimoto 2015+ Ford Mustang EcoBoost Direct-Fit Oil Cooler Kit, Part 1: Project Introduction and First Prototype Design

Interested in purchasing our Mustang EcoBoost oil cooler kit? Check out more details on our product page linked below!

Mishimoto Ford Mustang EcoBoost Oil Cooler Kit

Mishimoto 2015 Ford Mustang EcoBoost on dyno

Many of you have been following the video review series our team put together for our 2015 Ford Mustang EcoBoost PP. We were extremely excited to get this new vehicle into our shop to begin evaluating it for new product development. We searched for potential faults and areas where we thought additional cooling might be necessary. In one of our more recent videos, we highlighted some of the development taking place on our oil cooler kit for the EcoBoost. This direct-fit oil cooler kit is one of the first projects (along with a baffled oil catch can kit) our team tackled, because we knew that customers would prefer some extra cooling if they intended to put their Mustang through its paces, whether aggressive street driving, autocross runs, or days at the track. During the development process, we do extensive testing to ensure our product is performing to our standards, and to be sure that we are providing a high-value product that will benefit our customers.

If you aren't familiar with our brand yet, we welcome you to check out our introduction post linked below. This highlights a bit of our background, and explains what sets our company apart from others.

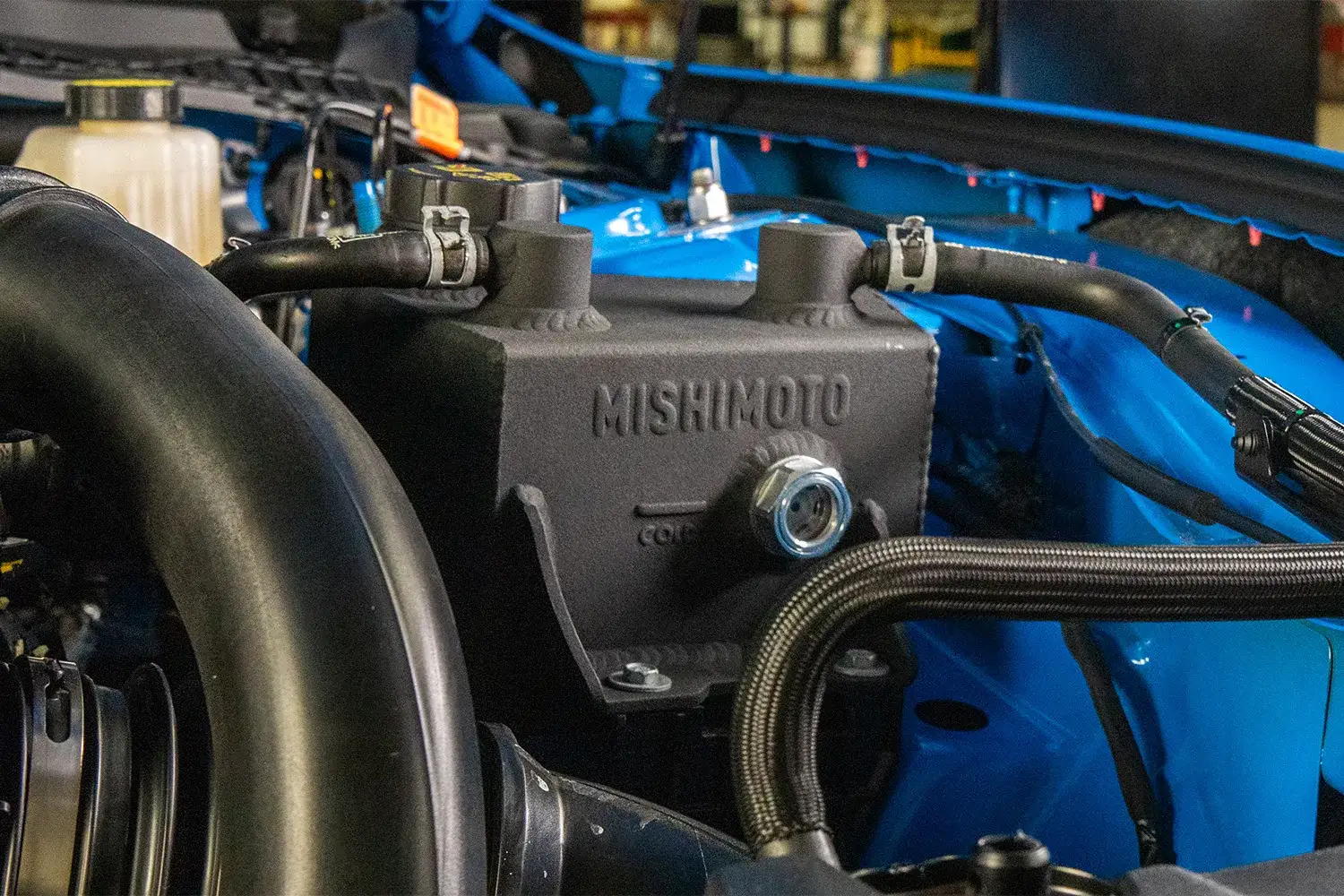

Ford 2.0L EcoBoost oil cooler

So, here is a shot of the oil filter housing on the Mustang EcoBoost. This is where we normally see some form of factory oil cooler.

Mishimoto 2015 Ford Mustang EcoBoost oil filter housing

In fact, even the 1.6L and 2.0L EcoBoost engines (2.0L shown in the engine image above) utilize such a system for oil cooler. It is interesting that Ford has left this particular component out of the Mustang. Once we begin testing, we should see what kind of temperatures we are dealing with in our completely stock Mustang. If high oil temperatures during track driving (due to lack of a factory cooler) become an issue, I am sure we will begin to see reports of limp-mode activation here on the forums.

A similar situation existed in 2006 with the inception of the BMW 335i, which was a twin-turbocharged 2- or 4-door RWD vehicle making power similar to the EcoBoost. Upon release, several vehicles were going into limp-mode during aggressive street driving because of high oil temperatures. BMW made a change midyear to add a liquid-to-air oil cooler, which helped alleviate some of the concerns.

We hope this will not be the case with the Ford!

So, we located the oil filter housing, and it appears we should have plenty of room for placement of our sandwich plate and routing of our lines. Next, we popped off the front bumper to check out space we could allocate for our heat exchanger.

Front bumper removed

Looks like we have plenty of real-estate! The only challenge will be developing brackets that use existing mounting points and ensuring that our cooler is achieving appropriate airflow.

So, with all this in mind, we set our engineers to work on developing our first prototype!

Preparation for prototype fabrication

First Prototype Fabrication

After looking over the available space, Steve (lead engineer for this project) began putting together plans for his first prototype design.

Prototype 1 bracket mock-up

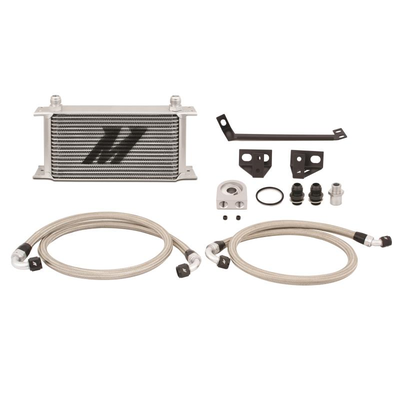

As you can see, we are using one of our 19-row stacked-plate fluid coolers. We have used this particular cooler for several of our direct fit kits, and it has proven to be extremely efficient for temperature reduction for vehicles with similar power output.

Now, similar to the Ford Focus ST, the Mustang features an active grille shutter system. This system closes off a large portion of the grille during specific driving conditions (engine warm-up and highway driving). Doing so provides more rapid engine warm-up and improved vehicle aerodynamics. Both of these benefits help to increase fuel mileage, which means a few more dollars in your pocket. These systems are pretty slick, however we will have to keep them in mind for our product design and testing processes.

Ford Mustang EB Active Grille Shutter

Check out a few shots of our first prototype design fully installed.

Prototype 1 mounted in grille

Prototype 1 mounted in grille

With our first option in place, our team evaluated the potential benefits and negative points for this particular mounting point.

First, the positive points. This cooler placement receives a reasonable amount of airflow. Around half of the cooler is exposed to airflow through the grille. Additionally, by placing the cooler to one side of the designated area, we can leave room for additional heat exchangers (such as an automatic transmission cooler). Finally, we found this particular location to be fairly aesthetically pleasing, with more of a subtle feel.

There is only one true downside to this location: airflow. Half of this cooler is blocked by the bumper support, meaning only a portion of the cooler is receiving proper airflow. Our product must provide function over form, so if we can squeeze out greater efficiency by mounting the cooler in a more appropriate location, we will certainly do so.

With this in mind, we decided to place this design to the side and work on a second location. Check back with us next time for a look at our second prototype!

Thanks for reading!